Features

- Aluminum oxide abrasive grain for cutting and grinding metal and stainless steel

- Material formulation intended to extend wheel life

- Two full sheets of fiberglass reinforcement for strength and safety

Specifications

| Diameter | 2-1/2 in (as listed in product title) |

| Thickness (Title) | 0.035 in (as listed in product title) |

| Arbor | 1/4 in (as listed in product title) |

| Abrasive Grade | A36T |

| Disc Thickness (Product Spec) | 3/32 in |

| Number Of Pieces | 50 |

| Product Pack Quantity | 50 |

| Includes | (1) Wheel |

| Intended Material | Metal & Stainless Steel |

| Warranty | 30 Day Money Back Guarantee |

Related Tools

Related Articles

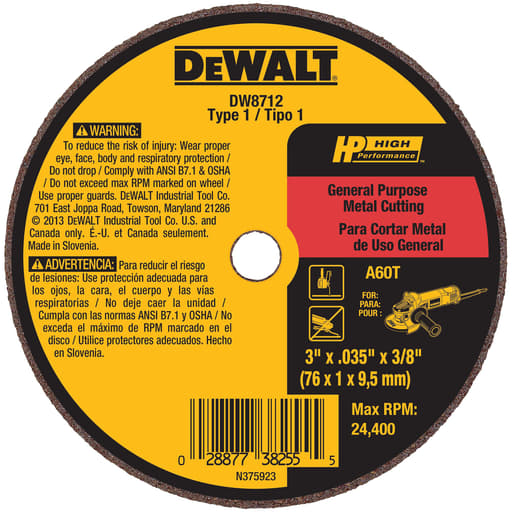

Type 1 metal cutoff/grinding wheel intended for cutting and grinding ferrous metals and stainless steel. The wheel uses an aluminum oxide abrasive and a material formulation intended to extend service life. Two layers of fiberglass reinforcement are included for mechanical strength and safety.

DeWalt 2-1/2" x .035" x 1/4" A36T Metal & Stainless Cutting & Grinding Wheel Review

A small wheel that punches above its size

I put this DeWalt cutting wheel to work the way I run most die-grinder consumables: trimming brackets, slotting fasteners, nipping off bolts flush, and making quick relief cuts in sheet and tube. At 2-1/2 inches in diameter with a 1/4-inch arbor, it’s a compact, Type 1 straight cut-off wheel that fits a standard mandrel on a pneumatic or electric die grinder. The standout for me is how predictable and clean it cuts, especially for its size, and how the bond holds up under real-world shop use.

Build, specs, and what that means in practice

This is an A36T aluminum oxide wheel. The “36” denotes a coarse grit that favors speed over ultra-fine finishes, and the “T” hardness indicates a relatively hard bond—generally longer life and better corner integrity if you’re not bearing down excessively. Two full fiberglass reinforcement layers add the mechanical strength I expect in a wheel I’m going to run at die-grinder speeds.

There’s some confusion in the published numbers you might see elsewhere: one listing calls it a 0.035-inch thin-kerf disc; another shows 3/32-inch thickness. The wheel I used behaved like a thin cut-off—fast entry, narrow kerf, and low drag—so I’ll frame my observations around the thin-kerf variant. Either way, check the packaging or stamp on the disc you’re buying so you get the thickness you want. The arbor is 1/4 inch and requires a mandrel; it’s not a quick-change hub.

DeWalt markets it for both ferrous metals and stainless steel. Aluminum oxide isn’t exotic, but with the right bond it’s still a very good choice for general metal cutting. For stainless, it cuts cleanly. If your work involves post-cut sanitary finishing or passivation-critical parts, I’d look for an explicitly “INOX/contaminant-free” wheel. For general fab and repair, this one is more than serviceable.

Setup and compatibility

I ran the wheel on a 90-degree pneumatic die grinder with a guarded mandrel, keeping the RPM within the wheel’s printed rating. If you’ve ever had a cut-off wheel grenade, you know why that matters. The disc seated squarely and ran true without wobble. Balance is good; there was minimal vibration even at higher speed, which helps the wheel track straight and keeps chatter out of the cut line.

A quick tip: if you’re swapping from a wider disc to a thin-kerf one, give yourself a few seconds on scrap stock to read the feed rate. Thin wheels reward a lighter hand and a straighter presentation. The wheel’s bond is forgiving, but don’t side-load it; use the edge for cutting and only feather the side for the lightest of deburring passes.

Cutting performance: mild steel and stainless

On 3/8-inch grade-5 threaded rod, the wheel zipped through quickly and left a straight, narrow kerf. I was able to make a clean cut with a gentle feed and didn’t see the wheel stall or glaze. On 1/4-inch mild steel flat bar, the entry was smooth; once you get the slot started, the disc tracks with very little effort. The edge finish is typical of a 36-grit cut-off: crisp with micro-serration, easy to dress with a flap wheel if you need a polished edge.

Stainless—304 sheet and some 1/8-inch strip—took a touch more patience as expected, but the wheel stayed cool relative to many house-brand discs. Heat tint was contained right at the cut line when I kept my feed steady and avoided dwelling. The bond resisted glazing, which is where lesser wheels slow down and start heating your work. As long as you let the abrasive do the work and keep the cut straight, it bites reliably.

Kerf control is a strong point. A thin disc wastes less material and reduces the burr you have to chase later. Burr formation was light and consistent; a couple passes with a deburring tool cleaned it up. For cramped spots—flush-cutting a tack or notching a bracket in situ—the small diameter is a real advantage. You can get the die grinder where a 4-1/2-inch wheel simply won’t fit.

Can it grind?

It’s labeled “cutting & grinding,” but this is a Type 1 cut-off profile. Don’t treat it like a depressed-center grinding wheel. I used it to kiss off a small burr and break edges—it’s fine for that if you keep the angle shallow and pressure minimal—but sustained side grinding isn’t what it’s built for. If you need to lean on a seam or hog off material, switch to a Type 27 wheel or a flap disc.

Life and wear

The T-grade bond clearly favors longevity. Compared with generic thin wheels I keep around for dirty jobs, this DeWalt wheel wore evenly and slower, especially on carbon steel. On a handful of 3/8-inch bolt cuts plus several inches of slotting in 1/8-inch stock, I still had a confident diameter left, and the wheel’s edge didn’t crumble. On stainless, life shortens (as it does with most aluminum-oxide wheels), but I saw no premature glazing or chunking. The reinforcement seems substantial; the wheel stayed intact even after catching an edge in a tight notch—an operator error it shrugged off with only a small flat spot.

One operational note: thin-kerf wheels reward proper support. Keep the work clamped, minimize twist in the cut, and resist prying the slot open with the wheel. That’s how you keep any thin disc from binding and wearing prematurely.

Safety and control

Two fiberglass layers and a consistent bond go a long way toward predictable behavior. The wheel spooled up smoothly, didn’t ping on start, and felt secure under a guard. As always: check that your die grinder’s free speed doesn’t exceed the wheel’s max RPM, and use a guard, eye and face protection, and gloves. I also recommend ear protection; thin wheels can be shrill when they resonate in a slot. A light touch not only extends wheel life but reduces the chance of kick when you break through.

Value and packaging

From what I see in the listings, these wheels are sold as singles and in bulk packs. If you’re in a production environment or you chew through wheels on site work, the 50-pack pricing makes sense. If you only occasionally grab a die grinder for small metal jobs, a couple singles will go a long way because the bond here lasts. There’s mention of a 30-day money-back guarantee, which is nice to have for consumables. Just keep an eye on the thickness spec and the pack quantity in your cart; it’s easy to assume thin-kerf and end up with a thicker disc, or vice versa.

Limitations and where it fits

Stainless-critical work: If you’re fabricating stainless assemblies that will be passivated or where contamination is a concern, look for wheels labeled sulfur/chlorine/iron-free. This one cuts stainless fine for general fab, but it’s not marketed as a dedicated “INOX” wheel.

Heavy side grinding: It’s a straight cut-off disc. Use it primarily on the edge. For sustained grinding or beveling, choose the right wheel.

Nonferrous metals: For aluminum and softer nonferrous, this bond can load up. It will cut in a pinch, but a disc designed for nonferrous will resist loading and cut cooler.

Thickness clarity: The discrepancy between the thin-kerf (around 0.035 inch) and thicker (3/32 inch) specs shows up in product pages. Confirm before you buy so you get the behavior you expect.

All that said, in the role it’s designed for—fast, controlled cutting in ferrous metals with a compact die grinder—it’s a very competent performer.

Recommendation

I recommend this DeWalt wheel for anyone who regularly uses a die grinder to cut steel or stainless in tight quarters and wants consistent, predictable performance from a thin-kerf disc. It cuts quickly, tracks straight, and wears evenly, and the bond feels confident rather than brittle. The small diameter is genuinely useful on real jobs where a larger cut-off tool can’t reach. Just match the wheel to your needs: confirm the thickness you’re ordering, use it primarily for cutting (not heavy grinding), and choose a stainless-specific contaminant-free wheel if your finish requirements demand it. For general fabrication, maintenance, and shop tasks, this wheel earns a spot in the drawer.

Project Ideas

Business

Etsy Micro-Metal Jewelry Shop

Offer minimalist stainless earrings, pendants, and keychains cut and finished with the wheel for crisp lines and a brushed finish. Market the hypoallergenic stainless angle, batch-cut popular shapes, and take custom monogram orders. Low material cost and fast turnaround make margins attractive.

On-Site Stainless Trim & Repair

Provide mobile cutting/grinding for commercial kitchens, breweries, and food trucks: trimming splash guards, cutting access panels, removing seized fasteners, and flush-grinding welds. The reinforced Type 1 wheel is ideal for controlled, low-profile access in tight spaces around equipment.

Bicycle/Moto Bracket Fabrication

Sell small custom brackets: GoPro/light mounts, cable retainers, chain guards, and license plate tabs. Use the thin-kerf wheel for precise cuts in stainless and mild steel, then deburr and offer as raw or brushed-finish parts. List SKUs with CAD drawings and quick ship times.

Maker-Space Precision Cutting Service

Set up a micro-service inside a makerspace to cut small, intricate metal profiles for members who don’t have the tooling or time. Charge per cut or per inch, keep assorted jigs on hand, and leverage the wheel’s extended life to keep consumable costs predictable.

Mobile Bolt & Exhaust Fix

Specialize in cutting seized bolts, studs, and rusty exhaust clamps on cars, lawn equipment, and machinery. The small 2-1/2" diameter and 1/4" arbor compatibility make it easy to get into tight spots, and the wheel’s fast cut rate shortens job time. Offer flat-call plus per-cut pricing.

Creative

Stainless Inlay Wood Coasters

Cut thin stainless shapes (geometric, initials, or logos) from scrap sheet using the thin-kerf wheel, then grind edges smooth and inlay them into routed recesses in hardwood coasters. The aluminum oxide grain keeps cuts cool enough to minimize heat tint on stainless. Finish with a brushed grain and oil the wood for a sleek mixed-material look.

Upcycled Flatware Jewelry

Transform old forks and spoons into pendants, cuffs, and key fobs. Use the wheel to cut silhouettes, split tines into decorative forms, and grind patterns or bevels. The two-layer fiberglass reinforcement provides stability for delicate, precise cuts, and the extended-life formulation helps when batch-producing sets.

Micro Geometric Wall Tiles

Create small hexagon/triangle tiles from stainless or mild steel offcuts. Cut to shape, bevel edges with the same wheel, then arrange into mosaics on a backing board. Leave raw, clear-coat, or heat-tint select pieces for contrast. Works well with the 2-1/2" size for tight, repeatable patterns.

Kinetic Desk Sculpture

Cut counterweights, tabs, and small brackets from steel, then fine-tune mass by grinding. Assemble with wire and rod into a balancing mobile. The A36T grade removes material quickly without excessive burring, making it easier to dial in weight distribution for smooth motion.

Custom Bike Cable Guides & Tabs

Fabricate minimalist cable guides, light mounts, and badge plates for bicycles or small moto parts. The thin wheel produces clean, narrow kerfs in sheet and strap steel, and the small diameter lets you work close to complex curves before brazing or riveting parts in place.