Features

- Compatible with Starlock interface

- Segmented design for plunge and flush cuts

- Titanium bi-metal construction (listed in product title)

- 0.25 in maximum immersion depth

- Sold as a single piece (pack quantity 1)

Specifications

| Model Number | OSL312T |

| Product Name | 3-1/2 in Starlock oscillating multi-tool titanium bi-metal segmented saw blade |

| Material (Title) | Titanium bi-metal |

| Material (Table) | Carbide RIFF |

| Width (In) | 3.5 |

| Immersion Depth (In) | 0.25 |

| Pack Quantity | 1 |

| Compatibility | Starlock oscillating multi-tools |

Related Tools

Related Articles

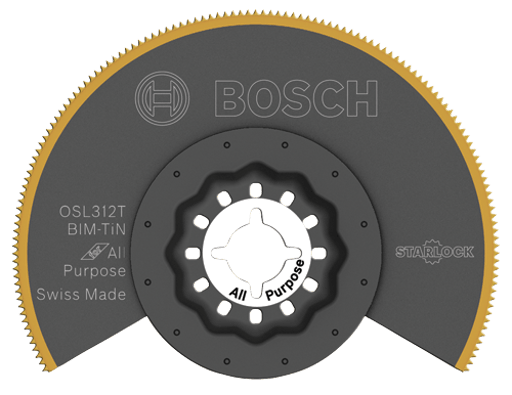

3.5-inch segmented saw blade for Starlock-compatible oscillating multi-tools. The blade is described as titanium bi-metal in the product title and is intended for segmented/plunge cutting. Listed immersion depth is 0.25 in.

Bosch 3.5 in Starlock oscillating multi-tool titanium bi-metal segmented saw blade Review

Why a segmented oscillating blade still earns a spot in my kit

I reach for straight plunge blades most days, but a good segmented blade solves problems those can’t: long, controlled flush cuts, notching without overrun, and trimming fasteners or flooring tight to surfaces. Bosch’s 3.5-inch Starlock segmented blade (OSL312T) has become my go-to for exactly those tasks. It’s sold as a single blade, sized generously at 3.5 inches across, and built for Starlock-compatible oscillating tools.

Before I get into performance, a quick note on the listing: I’ve seen this blade described both as “titanium bi‑metal” and as “carbide RIFF.” The sample I used (OSL312T) is a titanium‑coated bi‑metal toothed segment blade, not a carbide‑grit RIFF. That matters. Bi‑metal with a titanium nitride coating is what you want for general-purpose cutting in wood, plastics, and non‑ferrous metals, while RIFF (carbide grit) is what you’d pick for grout, tile backer, and masonry. If you need a carbide-grit segment blade, Bosch sells those as separate SKUs.

Design and build

The segmented form is essentially a partial ring with teeth along the arc. On this Bosch, the arc provides a long, stable cutting edge for scoring or trimming while the closed sides keep the blade rigid and easy to steer. The face is toothed—not grit—so it behaves like a fine metal-cutting blade in feel and feed. Teeth are uniform and cleanly ground, with a TiN coating that keeps heat at bay and resists galling.

Immersion depth is listed at 0.25 inches. That’s shallow compared to straight plunge blades and is the right way to think about a segment: it’s not for deep slots; it’s for controlled, shallow trimming and flush work where you’re riding the edge of the blade along a surface. The 3.5-inch diameter matters—it gives you a long arc to work with and a broad, stable footprint when referencing against casing, flooring, or a sill.

Starlock is the connection, and that’s a big part of why this blade feels solid in use. It locks positively with no slop, transmits torque efficiently, and lets you set the blade at whatever angle you need relative to the housing. On a dense cut, that tight fit reduces chatter and keeps the tool from “walking.”

Setup and compatibility

This is a Starlock blade. It clicks straight onto Starlock and StarlockPlus tools (Bosch, Fein, some Makita and others). If you’re running an older bolt-and-washer interface, you’ll need an adapter, and some platforms simply won’t accept Starlock at all. Be sure your tool is compatible before you buy; this blade has a closed mount, so it will not hang on a traditional open‑back post without the right adapter.

Orientation is easy to adjust. I often rotate it so the arc is just shy of parallel to the surface I’m trimming; that gives me sight down the edge and keeps the teeth from picking up adjacent material.

Performance in the field

Engineered hardwood and trim: Undercutting door casings for flooring is where this blade shines. With its wide footprint, I could register the arc along a scrap of flooring and sweep a flat, continuous cut. The cut face was clean with minimal fuzzing, and, importantly, I didn’t overcut into the jamb corners the way a straight blade sometimes forces you to do.

Metal flush cuts: Bi‑metal teeth with TiN handled nail stubs and finish brads without sparking out. On drywall anchors and small screws, cutting speed is respectable as long as you let the teeth work and keep oscillation speed in the mid-range. For hardened screws or stainless fasteners, it will cut—but slowly. That’s where a carbide-tooth or dedicated metal blade is faster. For occasional metal flush cuts, this blade is absolutely serviceable.

Plastics and PVC: Clean, controllable, and no melting when I kept speed down. The segment form helps here because you can ride the arc and make a guided cut without diving too deep.

Sheet goods: Scoring laminate and notching plywood backcuts went smoothly. The limited depth is actually a feature when you’re trying not to blow through veneer. For deeper notches, I had to switch to a plunge blade.

What I noticed most is how quiet and stable the cut feels compared to some universal-mount segments. With Starlock, the blade doesn’t ring or buzz under load. It starts smoothly, and the tool remains balanced even as you lean into the arc.

Control and line of sight

Segmented blades excel at maintaining a straight reference against a surface. The Bosch’s tooth geometry and steady arc allow you to “roll” into the material and keep the cut square. It’s also easy to stop the cut exactly at a corner: the shoulders of the segment are non-cutting, so you’re less likely to scar an adjacent jamb, tile, or baseboard. That’s a meaningful difference from straight blades that can overreach.

Durability and wear

After a few hours of mixed work—engineered flooring, pine casing, MDF, and a handful of nail stubs—the teeth still felt sharp and the coating showed only light polishing along the cutting edge. Heat buildup was modest; I could see mild discoloration after continuous cuts in hardwood, but no tooth bluing or chip-out. Compared to budget no‑name segments, the OSL312T holds its edge longer and is less prone to grabbing as it dulls. It doesn’t match the longevity of a full carbide-tooth metal blade in abusive metal-only situations, but that’s not its purpose.

Because the immersion depth is shallow, you’re spreading work along the full arc more than burying a small section. That helps distribute wear and extends life. If you habitually jam the leading edge into screws at full speed, you’ll shorten its life, but with basic technique the blade lasts.

Limitations

Depth: The 0.25-inch immersion depth is limiting for deep notches or mortises. If you need to go deeper, switch to a plunge blade.

Material confusion: Retail listings that conflate “titanium bi‑metal” with “carbide RIFF” create ordering risk. Verify the SKU and tooth style—this review is of the toothed bi‑metal segment.

Not the fastest on thick metal: It’ll get through copper and mild steel, but if you’re cutting metal all day, choose a carbide-tooth or carbide-grit option.

Price: Sold as a single blade, it sits at a premium. The value is in longevity and cut quality, not sticker price.

Who it’s for

- Flooring installers and remodelers undercutting casings and trimming transitions.

- Finish carpenters notching trim and casing without overcutting corners.

- Service techs and handypeople who need a reliable, versatile segment for mixed materials and flush work.

- DIYers who own a Starlock tool and want one high-quality segment blade that won’t chatter or wander.

Tips for best results

- Let the teeth do the work; use medium oscillation speed on hardwood and metal.

- Ride the arc against a guide (scrap flooring, a shim, or a straightedge) for perfectly flat undercuts.

- Feather into metal at a shallow angle to reduce tooth shock and heat.

- Keep a light touch near adjacent finished surfaces; the non-toothed shoulders are forgiving but not magic.

Value

If you only occasionally need a segment blade, cheaper options exist and will complete a few cuts. The Bosch earns its premium with a stiffer body, better torque transfer, cleaner cut faces, and slower wear. If time, precision, and finish quality matter—or you’re routinely trimming flooring and casings—the per‑job cost makes sense. If you’re primarily cutting fasteners or thick metals, a carbide-tooth segment might be a better investment.

The bottom line

Bosch’s 3.5-inch Starlock segmented blade combines a rock-solid mount with a well-executed bi‑metal tooth line and a practical 3.5-inch arc. It’s not a deep-plunge specialist, and it won’t outpace carbide on heavy metal, but for its intended work—flush trimming, controlled notching, and shallow cuts in wood, plastics, and light metals—it’s precise, predictable, and durable. The Starlock connection meaningfully improves feel and cut quality, and the blade holds up under real jobsite use.

Recommendation: I recommend this blade to anyone with a Starlock oscillating tool who needs a reliable, controllable segmented cutter for finish and flooring tasks. It’s a premium single blade, but the stability, cut quality, and wear life justify the spend if you value a clean result and fewer mid‑job blade changes. Verify you’re buying the toothed titanium bi‑metal version (OSL312T) and not a carbide‑grit RIFF if your work matches the use cases above.

Project Ideas

Business

Mobile Flush-Cut Finishing

Offer on-site trimming of proud dowels, plugs, shims, screws, and nails on cabinetry, stairs, and furniture. The segmented blade excels at flush work in tight spaces without harming surrounding finishes—perfect for punch-list contractors and millworkers.

Pallet Disassembly & Clean Boards

Cut nails between boards to quickly separate pallet slats with minimal damage, then sell cleaned, nail-free boards to makers and gardeners. Bi‑metal teeth handle hidden fasteners; segmented profile reaches tight seams.

Cabinet and Desk Cable Pass-Throughs

Retrofit neat cable notches and grommet holes in 1/4 in backs, drawer panels, and shelves on-site. The shallow 0.25 in immersion is ideal for thin panels and avoids blowout—market to offices and home studios.

Inlay Boards & Trays Shop

Produce and sell charcuterie boards, coasters, and trays with metal/wood inlays. Use the blade to plunge crisp inlay pockets and flush-trim inserts, enabling small-batch, customizable designs with low tooling costs.

Door and Hardware Touch-Ups

Provide quick service to adjust strike plates, shave shallow mortises, and trim proud hinge shims or fasteners up to 1/4 in depth without removing doors. Ideal for property managers and realtors needing fast, tidy fixes.

Creative

Brass-Inlay Coasters

Plunge shallow 1/8–1/4 in channels in hardwood blanks to inlay thin brass or aluminum strips in geometric patterns. The segmented blade lets you start and stop cleanly at corners, and the bi‑metal edge can nip thin metal to length. Sand and finish for a premium, giftable set.

Bow-Tie Inlay Repair Boards

Outline bow-tie (butterfly) shapes on live-edge or cracked boards and nibble the 1/4 in deep pocket with controlled plunge cuts. Fit contrasting wood inlays, then flush-cut any proud edges for a functional, decorative crack stop.

Flush-Cut Dowel Mosaic Tray

Glue a field of short dowels into a tray base, then use the blade to flush-cut all dowels level. The segmented profile helps get into edges and corners. Finish to reveal a tactile mosaic surface.

Upcycled Tin Lanterns

Use controlled plunge cuts to create star and window patterns in thin cans or sheet metal for candle lanterns. The bi‑metal teeth handle thin steel/aluminum, and the segmented arc helps trace curves. Deburr and add a handle.

Custom Plywood Vent Grilles

From 1/4 in plywood, plunge and connect parallel slots to form decorative return-air or radiator grilles. The 3.5 in segmented edge makes repeatable straight or arced cutouts with clean start/stop points.