Features

- More cuts and fewer blade changes

- Longer lifespan in stainless steel and thick metals

- Faster cutting in thinner metals

- Increased cuts per charge

- Variable teeth per inch (TPI) for versatility across metal thicknesses

- Optimized tooth design for clean cuts

- Manufactured in the USA with global materials

- Compatible with specific Milwaukee compact band saw models

Specifications

| Number Of Teeth | 260 |

| Tpi | 8/10 |

| Blade Length | 30.5625 in |

| Pack Quantity | 3 |

| Size | 30 9/16 |

| Weight | 0.321 lb |

| Height | 0.85 in |

| Width | 7.03 in |

| Material Thickness | Thick Metal |

| Material Application | Medium Metal |

Related Tools

Related Articles

These band saw blades are designed for cutting various metals efficiently, providing durability and performance for job site use. They are available in different sizes to fit multiple portable band saws.

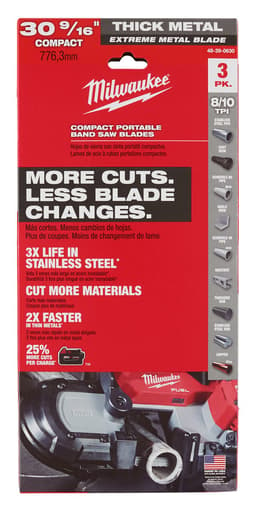

Milwaukee Extreme Metal Band Saw Blades Review

Every craftsman knows that the right blade can make all the difference when working with metals. Today, I’d like to share my experience with Milwaukee's Extreme Metal Band Saw Blades, model number 48-39-0630. These blades are designed to be durable, efficient, and versatile, making them suitable for a variety of job site applications. However, do they live up to the high standards Milwaukee typically sets for its tools? Let's find out.

First, let's talk about some of the key features that caught my eye. The blades boast an impressive claim of "more cuts and fewer blade changes," which immediately suggests longevity. Additionally, they are designed for fast cutting in thinner metals and promise to maintain performance in stainless steel and thick metals. The variable teeth per inch (TPI) offer versatility, theoretically allowing these blades to handle different metal thicknesses with ease. The blades are also optimized for clean cuts, which is crucial for precision work.

One of the things I appreciated about these blades is their compatibility with Milwaukee's compact band saw models. If you already own a Milwaukee band saw, these blades promise a seamless fit, which is always a plus. Moreover, the fact that they are made in the USA with global materials adds a layer of confidence regarding their quality and craftsmanship.

When I first put these blades to the test, the initial cuts were impressive. The blades sliced through thin metals like butter. For tasks requiring precision and speed, such as cutting conduit or threaded rods, the blades performed admirably. The clean cuts were a significant advantage, especially when working on detailed projects where precision is key.

However, as I continued to use the blades, I encountered some issues that were hard to overlook. Durability, one of the main selling points, seemed to falter. After a relatively short period of use, I noticed that the blades began to dull quite rapidly. This was particularly evident when cutting through thicker metals or harder materials. For instance, cutting through rebar or steel pipes proved challenging as the blades lost their sharpness quickly, requiring frequent replacements.

In terms of longevity, I expected more from a brand like Milwaukee. The blades snapped at the welds on multiple occasions, which was both frustrating and disruptive. I had to pause my work to replace the blades, which not only slowed me down but also increased the overall cost of the project. For a tool that promises fewer blade changes, this was a significant drawback.

Additionally, there were instances where the blades broke into pieces within a short span of use. This was concerning because it indicated potential flaws in the manufacturing process or material quality. When working on professional projects, reliability is non-negotiable, and these blades fell short in that regard.

Despite these issues, there were moments where the blades redeemed themselves. For cutting applications involving softer metals or materials like EMT and PVC, the blades performed satisfactorily. They managed to cut through these materials without much trouble, which suggests they might be more suited for lighter-duty tasks.

It’s also worth mentioning that the variable TPI design did offer some versatility. When switching between different metal thicknesses, the blades managed to adapt reasonably well, providing clean cuts across various materials. However, this versatility was somewhat overshadowed by the durability issues, as the need for frequent replacements negated the convenience of having a blade that could handle multiple tasks.

One area where these blades excelled was in compatibility. They fit perfectly with my Milwaukee M12 saw, which made installation straightforward and hassle-free. The convenience of having a blade that integrates seamlessly with my existing tools was a definite plus.

In summary, Milwaukee's Extreme Metal Band Saw Blades show promise but fall short in critical areas such as durability and longevity. While they offer clean cuts and perform well in lighter-duty applications, their inability to maintain sharpness and tendency to break at the welds are significant drawbacks. For professionals who require reliable and long-lasting blades for heavy-duty tasks, these blades might not meet expectations.

Based on my experience, I would hesitate to recommend these blades for those who frequently work with thick or hard metals. The frequent need for replacements and the associated costs could outweigh the initial convenience and performance benefits. However, if your work primarily involves cutting softer metals or lighter materials, these blades could still be a viable option, provided you are prepared for potential durability issues.

Ultimately, while Milwaukee has a reputation for high-quality tools, the Extreme Metal Band Saw Blades have room for improvement. If Milwaukee can address the durability concerns and enhance the blade's longevity, they could become a go-to choice for metal cutting applications. Until then, it might be worth exploring alternative options that offer better reliability for demanding tasks.

Project Ideas

Business

Custom Metal Fabrication Services

Offer metal cutting and fabrication services to local businesses and hobbyists. Market the precision and efficiency of your cutting services using these high-quality band saw blades.

Metal Art Commissions

Accept commissions to create custom metal art pieces for clients. Utilize the saw blades to deliver high-quality, detailed work that meets client specifications.

Metal Furniture Line

Launch a line of custom metal furniture. Use the band saw blades to produce consistent, high-quality pieces that can be sold online or through local retailers.

Workshop Classes

Offer classes and workshops teaching metalworking techniques using band saws. Charge a fee for participation and provide hands-on experience with metal cutting and fabrication.

Metal Part Production

Produce and sell custom metal parts for machinery, automotive, or construction purposes. Leverage the precision and efficiency of the band saw blades to ensure high-quality parts.

Creative

Metal Sculptures

Use the band saw blades to create intricate metal sculptures. The precision and durability of the blades will allow for detailed cuts in various metals, enabling the creation of custom art pieces.

Custom Metal Furniture

Design and build unique metal furniture pieces like chairs, tables, and shelves. The band saw blades can handle different metal thicknesses, making it easy to create sturdy and stylish furniture.

Metal Jewelry

Craft delicate and detailed metal jewelry such as rings, bracelets, and necklaces. The fine cuts enabled by the band saw blades will allow for intricate designs and clean finishes.

Decorative Wall Art

Create custom metal wall art pieces. Utilize the saw blades to cut various shapes and designs from metal sheets, then assemble and finish them for a professional look.

Model Making

Build detailed metal models of vehicles, buildings, or other structures. The precision cutting capability of the band saw blades will help in achieving accurate and intricate parts.