Features

- Tungsten carbide teeth for improved edge life

- Thin (ultra-thin) kerf for faster cutting and reduced material removal

- Ribbed heat vents to reduce blade temperature and flexing

- Anti-stick coating to minimize gum-up and friction

- Includes two blades in the combo pack

Specifications

| Product Diameter | 5-3/8 in |

| Kerf Thickness | 0.059 in |

| Number Of Teeth | 30 |

| Tooth/Hook Angle | 3° |

| Includes | 2 blades |

| Tooth Material | Tungsten carbide |

| Arbor Size | 0.3937 in |

| Warranty | 30-day money back guarantee |

Related Tools

Related Articles

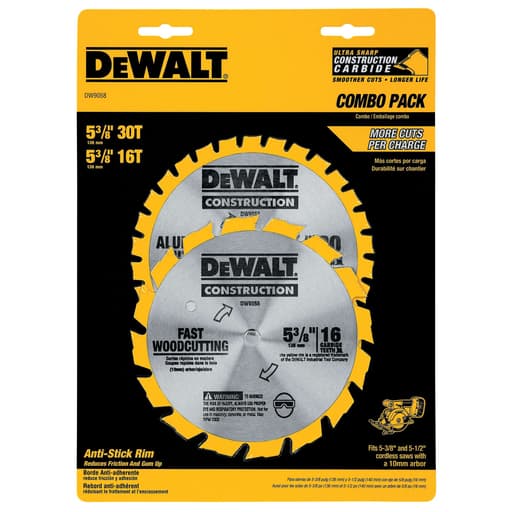

Set of small-diameter construction saw blades with tungsten carbide teeth and a thin kerf designed for durable, fast, and smooth cuts in a variety of building materials. Ribbed heat vents help reduce operating temperature and blade flexing. An anti-stick coating reduces friction and material buildup.

DeWalt 5-3/8 in. 16T/30T Construction Saw Blade Combo Pack Review

Why I reached for this combo

In compact saws, blade choice matters more than you think. With a 5-3/8-in saw, you don’t have a lot of spare torque or plate thickness to hide flaws—every design decision shows up in the cut. That’s exactly why I put the DeWalt combo pack (a 16T and a 30T blade) through a few weeks of framing, sheet-goods work, and trim repairs. I wanted to see if a thin-kerf, small-diameter, tungsten-carbide set could be a true do-most-things pairing for a compact circular saw.

Setup and compatibility

This pack uses a 10 mm (0.3937 in) arbor. That’s perfect for many compact 5-3/8-in cordless saws but won’t fit saws with a 5/8-in arbor without a bushing—and I don’t recommend relying on reducer rings for high-speed tools unless the blade and saw manufacturer explicitly allow it. If your saw calls for a 10 mm arbor, these mount securely and run true.

Out of the sleeve, both blades were flat with no visible plate runout. The anti-stick coating was even, and the ribbed vents are more substantial than simple cosmetic slots—they’re formed, not just laser-cut, which helps keep the plate stable under heat.

What’s in the pack and why it matters

- 16-tooth blade: Fast, aggressive, and suited to framing, rough ripping, and general-purpose site cuts.

- 30-tooth blade: Cleaner crosscuts, sheet goods, and finish-adjacent work where splintering and tear-out matter.

Both blades share the same thin 0.059-in kerf and a modest 3° hook angle. That hook angle is a smart choice for compact saws: it reduces self-feeding and kick while giving you better control on plunge starts and crosscuts.

Cutting performance

I started with the 16T in construction lumber—SPF studs, pressure-treated deck boards, and a few knottier pieces of Doug fir. The blade gets up to speed quickly and bites without the lurch you can get from high-hook framing blades. In 2x PT, it ripped efficiently and stayed on line without wandering, provided I kept a steady feed. With the kerf this thin, you’ll feel it if you push too hard—the plate reminds you with a faint singsong—but normal feed pressure keeps chatter in check.

Switching to the 30T for plywood and trim repairs, cut quality was noticeably cleaner. On sanded ply and primed finger-joint stock, top-face tear-out was minimal even without tape; a slow feed and a shallow scoring pass produced a glue-ready edge. On veneered plywood, I still recommend a score cut, but the 3° hook helps keep fibers from lifting.

I used the 30T for light-duty composite and plastic cuts (PVC trim and a handful of polycarbonate sheets). The anti-stick coating did its job—no gummed-up shoulders, and chips cleared well. If you work in resinous pine, that coating matters; I didn’t have to stop and scrape pitch mid-day.

Durability and heat control

Thin kerf blades can be drama queens when they heat up. Here, the ribbed vents noticeably help. After repeated rips in PT, the plate stayed flat enough that I didn’t need to nurse the saw to prevent a wave. The coating fought friction, and I didn’t see the familiar crescent of burned wood that cheaper coatings can leave on longer crosscuts.

Edge life was solid. After framing two small closet openings, rough-ripping a dozen PT deck planks to width, and breaking down sheets for shelving, the 16T still cut straight; I noticed a minor reduction in feed speed but no chipped teeth. The 30T, after a day on ply and trim, still delivered clean edges. It’s not indestructible—if you hit a fastener, you’ll chip a tooth—but the tungsten carbide holds up as expected for a quality construction blade.

Accuracy and feel

With compact saws, balance and plate stiffness influence the “paint line” accuracy you can trust. Both blades tracked well. The 16T has a predictable, linear feed—no sudden burps—and the saw’s base stayed seated on rips across knots. The 30T, thanks to the low hook and tooth count, felt composed on plunge cuts for outlet openings and window shims; it doesn’t yank forward when you drop in.

Noise is typical for a thin-kerf small blade: a higher-pitched note under load with a slight whistle at full RPM in free spin. Under cut, the vents damp some of the chatter. Vibration through the handle is low if your saw’s flange is clean and you don’t over-tighten the nut.

Battery life on cordless saws

This is where the thin kerf pays off. On a 20V compact saw, I consistently got more cuts per charge than with a standard-kerf 24T I had on hand. The difference was most obvious when ripping PT, where the kerf reduction compounds with the lower tooth engagement of the 16T. If you spend days on a ladder or in tight spaces where battery swaps are a hassle, that matters.

Materials beyond wood

For plastics and composites, the 30T worked well with a light touch. For non-ferrous metals, I keep expectations conservative; while carbide teeth will physically cut thin aluminum, these are construction blades, not dedicated non-ferrous or steel blades. For occasional, careful cuts in thin aluminum stock at slow feed and with secure clamping, the 30T handled it, but I wouldn’t make that a habit. For ferrous metals, use a blade rated specifically for that purpose.

What could be better

- Limited diameter: 5-3/8 in is, by design, a compact-saw size. Your maximum depth of cut is limited compared to 6-1/2-in saws. That’s not a flaw of the blade, but it defines its job.

- Ultra-thin kerf sensitivity: Push too hard, and you’ll hear the plate sing. It stays true if you let the saw work, but aggressive feed on dense hardwood can induce a slight wobble.

- Arbor specificity: The 10 mm arbor is perfect for the saws it’s meant for, but if your compact saw uses 5/8 in, you’ll need a different blade rather than trying to force compatibility.

Who it’s for

- Remodelers and framers running compact cordless saws who want a two-blade solution: 16T for fast framing cuts, 30T for cleaner sheet-goods and trim repairs.

- DIYers who primarily break down plywood and make occasional framing cuts and want better battery life from a thin-kerf design.

- Punch-list pros who value control on plunge cuts and reduced kick thanks to the modest 3° hook.

Standout details

- 0.059-in kerf strikes a nice balance between speed and plate stability. You get the efficiency benefits without wandering if you use reasonable feed rates.

- Ribbed heat vents do more than market the blade—they keep the plate from walking during long rips and reduce the chance of heat-induced warp.

- The anti-stick coating resists pitch build-up, which is noticeable in PT and sappy pine. It also wipes clean easily.

- A 30-day money-back guarantee isn’t a lifetime promise, but it’s enough to try the set on your saw without buyer’s remorse.

Bottom line

As a two-blade kit for compact circular saws, this DeWalt combo pack hits the right notes. The 16T is a fast, controlled workhorse for framing and rough work; the 30T delivers clean, predictable cuts in sheet goods and finish-adjacent tasks. Both benefit from the thin 0.059-in kerf, the low 3° hook for control, and heat-dissipating vents that keep the plate honest when the cut gets long.

Recommendation: I recommend this combo for anyone running a 5-3/8-in compact saw with a 10 mm arbor who needs a simple, reliable two-blade quiver. The combination of edge life, cut quality, and battery-friendly kerf makes it a practical upgrade over generic stock blades. Just match the blade to the task—16T for speed, 30T for finish—and let the saw do the work. If your saw uses a 5/8-in arbor or you routinely cut metals, look elsewhere; otherwise, this set is an easy yes.

Project Ideas

Business

Accent Slat Wall Microbusiness

Offer turnkey slat wall installations for homes and small offices. Rip slats on-site to custom widths with the 16T blade, then finish and install with minimal mess thanks to the thin kerf and compact saw compatibility. Sell tiered packages (material choices, backer acoustics, lighting).

Mobile Cut-to-Size Service

Provide on-site panel and trim cutting for DIYers, van builders, and property managers. The 5-3/8 in. blades pair with cordless saws for safe indoor use; the 30T blade delivers finish-ready edges on plywood and trim, while the 16T handles quick rips. Charge per cut and offer layout optimization.

Flat-Pack Furniture Kits

Design and sell minimal-waste plywood kits (stools, shelves, planter boxes) precut with clean 30T finish edges and labeled parts. Market locally and online; customers assemble with basic tools. Thin-kerf blades reduce waste per sheet, improving margins.

Custom Wood Mosaic Art Shop

Create and sell geometric wall art from reclaimed flooring or offcuts. Use the 30T blade for crisp tile pieces and the 16T for rapid batching. Offer bespoke colorways and sizes; monetize via Etsy, craft fairs, and corporate decor commissions.

Trim and Small-Job Finishing Service

Specialize in small interior jobs: casing doors/windows, replacing baseboards, and repairing damaged trim. The 30T blade ensures clean miters and minimal tear-out on painted or stained trim; the anti-stick coating helps when cutting prefinished materials. Offer fast, fixed-price packages.

Creative

Geometric Slat Wall Panels

Rip long, consistent slats from plywood or cedar using the 16T blade for fast rips and the 30T for clean crosscuts to length. Create modern acoustic accent walls or headboards by spacing slats over felt or black-painted backer. The thin kerf minimizes waste and battery draw on compact saws, and the anti-stick coating helps when cutting resinous softwoods.

Kerf-Bent Lamp or Planter Sleeve

Use closely spaced kerf cuts to bend a thin plywood panel into a cylinder or gentle wave for a pendant lamp shade or a decorative planter wrap. The ultra-thin kerf allows controlled flexibility and less material removal, while the ribbed heat vents help keep cuts straight during repeated passes.

Modular Hex Shelves

Cut 30° miters for hexagon shelf modules. Use the 30T blade for crisp miters and visible edges; use the 16T to rip strips to consistent widths. Assemble multiple hexes into wall-mounted honeycomb storage. The compact 5-3/8 in. format excels in tight shop spaces and on makeshift jobsite benches.

Laminated Plywood Stool

Rip and crosscut thin plywood laminations, glue into a block, then facet the edges with controlled straight cuts for a sculpted, geometric stool. The thin kerf reduces saw marks and sanding time, and carbide teeth stay sharp through glue lines and engineered wood.

Cedar Planter Benches

Build outdoor planter boxes that double as seating using cedar fence pickets and 2x stock. The 16T blade speeds through rips and bevels; the 30T handles clean trim cuts and miters for corner wraps. Anti-stick coating helps reduce pitch buildup for consistent results.