Features

- Up to 250 lb clamping force

- Includes two table clamps for mounting to a work surface

- Pivoting threaded screw to accommodate different board thicknesses

- Fixed 90° hold for corner and T‑joint assembly

- Comfort grip handle for manual tightening

- Easy access for fastening while clamped

Specifications

| Clamp Type | Angle/Corner |

| Clamping Strength (Lb) | 250 |

| Clamping Force (Kg) | 113 |

| Maximum Opening (In) | 4 in |

| Jaw Opening (In) | 2 in |

| Jaw Width (In) | 4 in |

| Throat Depth (In) | 4 in |

| Jaw Depth (Mm) | 30 |

| Jaw Width (Mm) | 100 |

| Clamping Capacity (Mm) | 57 |

| Distance Between Centers Of Fixing Holes (Mm) | 63 |

| Body Material | Steel |

| Handle Material | Soft grip |

| Handle Type | Quad-lobe |

| Number Of Pieces | 1 |

| Packaging | Blister |

| Product Weight (G) | 1300 |

| Product Weight (Kg) | 1.3 |

| Product Weight (Lbs) | 2.8 |

| Warranty | Limited lifetime warranty |

| Returnable | 90-Day |

Related Tools

Related Articles

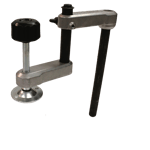

A right-angle clamp intended to hold two workpieces at a fixed 90° for assembly and fastening. It uses a threaded screw with a rubberized handle to apply clamping force and includes two removable table clamps for mounting to a bench or work surface. The screw pivots to accommodate different material thicknesses and provides access for fasteners.

DeWalt 90-Degree Angle Clamp Review

Why I picked it up

Squaring casework and small cabinet boxes is the sort of task that either goes smoothly or becomes a slow dance of clamps, shims, and quiet frustration. I wanted a dedicated solution that would hold corners at a true 90 without a lot of fuss, give me access for fastening, and be robust enough to live on my bench for years. That’s what led me to the DeWalt angle clamp. After several projects—drawers, a couple of small cabinets, a bookshelf with T‑joints—I’ve got a good feel for where it excels and where it could be improved.

Build and design

This is a heavy, steel-bodied angle clamp with a pivoting screw and a comfortable quad‑lobe handle. At 2.8 pounds, it feels substantial in the hand and it’s clearly built to take shop abuse. The cast body resists flex under load, which matters when you’re counting on the clamp itself to keep corners square. The screw runs smoothly and threads into a polymer housing; I stayed strictly with hand torque and never felt close to its rated 250 lb clamping force. The handle has enough contour to generate real pressure without tearing up your palm.

A small but meaningful design choice: the screw handle sits outside the corner you’re clamping. That keeps the interior of boxes clear and makes it easier to clamp multiple corners at once on larger assemblies without interference between tools.

Setup and mounting

Out of the box, I could use it freehand, but the included table clamps make a big difference in control. The base has through-holes on both axes, so you can mount the clamp oriented either way and lock it to a bench or an MFT top. With the clamp fixed, alignment becomes straightforward: set your reference piece against one jaw, bring the mating piece into place, and tighten. Being able to use the clamp as a small fixture rather than chasing the workpiece around the bench improves speed and repeatability, particularly on T‑joints.

The base holes line up nicely for permanent or semi-permanent setups. I’ve also used the two removable table clamps to temporarily anchor the tool to a cabinet side while assembling in situ. That flexibility is a practical advantage over simpler corner clamps that can’t be mounted.

Capacity and clamping performance

The working capacity is well matched to furniture and cabinetry. The jaws are 4 inches wide with a throat depth around 4 inches, and the clamping capacity is roughly 2 inches—comfortably takes 3/4-inch panels, face frames, and 1‑1/2-inch thick 2x stock. The pivoting screw is the star here. Because the screw pivots, it equalizes pressure on dissimilar thicknesses, letting me clamp, say, a 3/4-inch shelf to a 1‑1/2-inch gable without racking the joint.

Pressure application is controlled and predictable. A few turns snug the work; a few more lock it. With moderate hand force, I had zero creep while drilling pilot holes and driving fasteners. The casting keeps things rigid, and the broad jaws distribute load well enough that I didn’t see denting in softwoods, though on painted or soft stock I still stick a thin pad between the jaw and workpiece as a best practice.

Working access and real-world use

Access for fasteners is excellent. The open interior of the clamp gives plenty of room for drills and drivers; I could run pocket screws, confirmat screws, and standard wood screws without needing to reposition. On drawers and small boxes, the outside handle location is especially handy—you can clamp all four corners on a larger box because there’s nothing protruding inside the cavity.

For T‑joints, the clamp behaved like a little third hand. I’d mount the tool to the bench, set the vertical workpiece against one jaw, lay the horizontal shelf across, spin the handle, and the joint would hold square while I checked reveal and drove fasteners. It was quick and repeatable.

Accuracy and repeatability

I checked the fixed 90 against a reliable machinist square before first use and again after several weeks; the register surfaces on my unit are dead on. In practice, assemblies came off the clamp square without a fight. On cabinet carcasses, diagonals matched within a millimeter or so over 600 mm, which is what I expect when parts are cut accurately. The more rigid the clamp body, the more confident I feel pushing to final torque without fear of introducing twist, and this one inspires confidence.

Ergonomics and ease of use

The quad‑lobe handle is a smart shape: easy to grip, good leverage, and comfortable over repeated cycles. The screw thread is cut cleanly, so it doesn’t bind or gall; a light wipe of paste wax on the thread made it even smoother. Because the screw pivots, setup is forgiving—you’re not fighting to shim two different thicknesses level before you tighten. The jaws have enough area to register parts consistently, and the open design gives good visibility.

Weight is both an upside and a downside. The mass helps stabilize the work, especially when mounted. But if you’re juggling the clamp with one hand and a long workpiece with the other, the bulk can make the first few alignments feel clumsy until you develop a rhythm.

Where it shines

- Casework and cabinet boxes where you want reliable 90‑degree corners

- T‑joints for shelves and partitions

- Face frame alignment before nailing or screwing

- Small production runs where repeatability matters

- Situations where you want to clamp four corners at once without tools colliding inside the cavity

In each of these, the combination of true 90, open access, and the pivoting screw make day-to-day work smoother.

Limitations and nitpicks

- It’s a single‑purpose tool locked at 90. If you need odd angles or mitered corners, this isn’t the clamp.

- The body is chunky. In tight interiors or against deep rabbets, it can block a driver in certain orientations. A stubby bit or right‑angle attachment solves most of this.

- The screw threads into a polymer nut. It seems stout, but over‑torquing is not your friend. The rated 250 lb is more than ample—hand tight is all you need.

- The jaws are bare metal. On delicate finishes or softwoods, add pads or blue tape to prevent marring.

None of these are deal‑breakers, but they’re worth knowing before you rely on it for the first glue-up.

Durability, warranty, and value

The steel casting and smooth screw threads suggest long service life if you keep the threads clean and avoid abuse. I’ve knocked it around the bench and dropped it once with no ill effects beyond a cosmetic scuff. The brand’s limited lifetime warranty adds peace of mind, and a 90‑day return window is generous if you discover it doesn’t fit your workflow. Considering the build, included table clamps, and real-world performance, the value is solid for anyone doing regular square assemblies.

Tips from the bench

- Mount it. Using the included table clamps to anchor the tool greatly improves speed and accuracy.

- Light torque. Stop when your parts stop moving—more force isn’t better.

- Pre‑drill. Even with strong clamping, pre‑drilling keeps parts from shifting and preserves alignment.

- Pad the jaws for soft or finished stock.

- Keep a small brush near the bench to clean sawdust from the screw threads; a waxed thread turns more smoothly and lasts longer.

Recommendation

I recommend the DeWalt angle clamp to anyone who regularly builds boxes, cabinets, drawers, or shelves and wants reliable 90‑degree alignment with easy access for fastening. Its rigid steel body, pivoting screw, and included table clamps make it a practical, repeatable fixture rather than just another clamp. It’s not the right tool for mitered frames or odd angles, and its bulk can be awkward in tight spots, but for square assembly work it’s accurate, strong, and comfortable to use. If your projects live in the world of right angles, this clamp earns a dedicated spot on the bench.

Project Ideas

Business

Boutique Picture Frame Micro‑Shop

Offer custom and standard-size frames with dead-square corners. The clamp lets you glue and pin mitered corners with minimal setup, improving consistency and throughput. Batch production by bench-mounting two clamps to assemble multiple corners at once; upsell mats and hanging hardware.

On‑Site Cabinet Face‑Frame and Shelf Install

Provide mobile assembly and repair services for face frames, shelves, and corner cabinets. The clamp keeps rails and stiles square while you pocket-screw on site, reducing rework in tight spaces. Market to realtors and property managers for quick turnarounds between tenants.

Planter Box Pop‑Up for Markets

Produce clean, modern planter boxes and sell at weekend markets or via local garden centers. Use the clamp for fast, square assembly and hidden fastening, then finish in seasonal colors. Offer custom sizes within the clamp’s capacity and bundle with liners for higher margins.

DIY Workshop Classes: Square Joints 101

Run paid classes teaching beginners how to assemble square boxes, frames, and T-joints. Set up multiple benches with mounted clamps so students get hands-on success quickly. Monetize via class fees, materials kits, and tool affiliate links or on-site sales.

Small‑Batch Metal Brackets and Racks

Sell powder‑coated L‑brackets, cube frames, and wall rack components to local shops and Etsy buyers. The clamp ensures accurate 90° alignment for drilling, bolting, or light welding, speeding up jig-less production. Offer custom sizes and bulk pricing to interior designers and makers.

Creative

Splined Miter Keepsake Box

Build a small keepsake box with mitered corners reinforced by contrasting wood splines. Use the clamp to hold each 90° corner perfectly while you glue and pin-nail, then cut spline kerfs after the glue cures. The pivoting screw accommodates different side thicknesses, and the open corner lets you drive brads or insert biscuits without removing the work.

Geometric Shadow Box Shelves

Create a set of square and rectangular shadow boxes for a gallery wall. The fixed 90° hold helps you assemble T-joints and corners square so boxes hang flush. Batch the process by mounting the clamp to the bench with the table clamps for consistent, repeatable alignments across a whole set.

Cedar Cube Planter Trio

Make three outdoor planters with clean 90° corners and hidden fasteners. The clamp’s easy access lets you pre-drill and screw from the inside while the sides are held square, so the exterior faces stay pristine. Size the panels to the 4 in opening for effortless assembly and repeatable results.

Right‑Angle Desk Organizer

Build an L-shaped desktop caddy with vertical dividers for mail, notebooks, and devices. Use the clamp to accurately join the base and back at 90°, then add dividers as T-joints without losing alignment. The 250 lb clamping force keeps parts from creeping during glue-up.

Metal Angle Shelf Brackets

Fabricate minimalist 90° metal brackets from angle iron or flat bar. The clamp holds stock square while you drill and bolt or tack-weld. If welding, protect the clamp from spatter with heat shields and keep the screw threads clear; the steel body and fixed geometry help prevent twist.