Features

- Dense diamond concentration to reduce chipping and tile breakout

- Ultra-tensioned plate to reduce vibration and improve cut straightness

- Continuous rim for smooth wet cutting of glass tile

- Intended for wet cutting applications

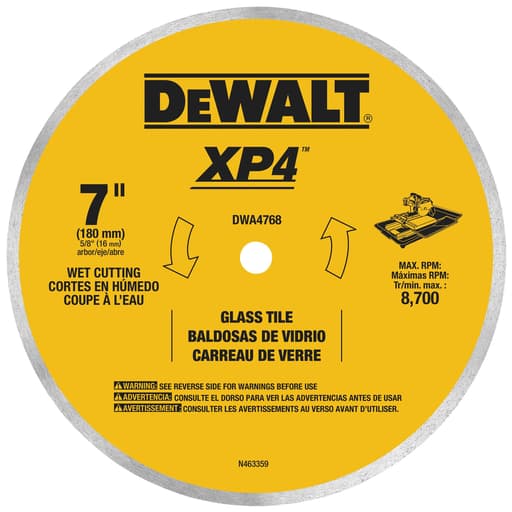

Specifications

| Arbor Size (In) | 5/8 |

| Diameter (In) | 7 |

| Rpm | |

| Intended Use | Wet cutting of glass tile |

| Recommended Materials | Glass tile (not recommended for ceramic or porcelain) |

Related Tools

Related Articles

Continuous-rim diamond blades designed for wet cutting of glass tile. The diamond concentration and tensioned plate reduce chipping and vibration for smoother, straighter cuts. Not intended for use on ceramic or porcelain tile.

DeWalt XP4 Glass Tile Blade Review

Why I reached for this blade

A glass backsplash and a couple of custom glass shelves pushed me to reach for the XP4 glass blade. Glass can be unforgiving: it’s brittle, it shows every chip, and it punishes any wobble or heat buildup. I wanted a blade that prioritized edge quality over speed, and the XP4 is designed specifically for wet cutting glass with a continuous rim and a tensioned plate to keep things stable. That purpose-built approach shows up in use—when you set it up correctly.

Setup and compatibility

The XP4 is a 7-inch blade with a 5/8-inch arbor, so it drops onto most small to mid-size wet tile saws without fuss. I ran it on a well-aligned sliding table saw with solid water delivery. If your saw’s pump is weak or the nozzles aren’t aimed right at the cut, fix that before blaming the blade—glass demands consistent cooling and slurry removal.

Out of the wrapper, I gave the blade a brief break-in on a dressing stone. It’s not strictly required, but it made the first cuts a touch smoother and helped keep the diamonds exposed. I also checked runout with a dial indicator; even a few thousandths of wobble at the arbor will show up as micro-chipping on glass. The XP4’s plate is impressively true—no noticeable wobble, and it rings like a tensioned blade should.

Cutting performance on glass tile

On 3x12 glass “subway” pieces and on mesh-backed mosaics, the XP4 produced clean edges with minimal flecking. The continuous rim does what it’s meant to do—there’s no segment-to-segment thump, and the cut feels controlled. With typical tempered or back-painted glass tile, exit-chip is the Achilles’ heel. The XP4 kept it in check as long as I did two things:

- Slowed the feed through the last 1/2 inch of the cut.

- Supported the tile fully so nothing cantilevered off the tray.

I also pulled a couple of cuts with the paint face down to compare results. Face-down cuts were marginally cleaner on the visible edge but risked scratching the surface if any grit got under the tile. A strip of blue tape across the cut line helped in both orientations but wasn’t essential with this blade—more of a belt-and-suspenders step for fussy finishes.

On thicker, cast glass shelves, the XP4 could handle the cut but not quickly. This is a finish-first blade; if you push it, heat climbs and the edge starts to pepper. When I kept the feed slow and steady, water flow high, and paused midway to clear slurry, the exits stayed tidy with only a whisper of haze that hand-buffed out with a 200-grit diamond pad.

Vibration, noise, and tracking

The “ultra-tensioned” plate reads like marketing until you put the blade to work. It tracks straight, resists deflection on longer rips, and doesn’t telegraph motor vibration the way thinner, cheaper glass blades can. On my saw, there was no audible flutter even at full depth. That stability shows up most on narrow rip offcuts—those are where glass likes to chip out. The XP4 kept those slivers intact more often than not, which is a quiet testament to plate stiffness and balance.

Speed and finish

This blade is tuned for finish quality, not production speed. I’d put it in the “medium-slow” category for glass. If you’re used to pushing porcelain blades, recalibrate: the XP4 rewards patience. Trying to force it will glaze the rim and increase chip-out. Treated as a precision tool—steady pressure, consistent cooling—it returns a factory-like edge that needs little or no cleanup.

Blade life and maintenance

I dressed the XP4 periodically with a silicon carbide dressing stone, especially after long, uninterrupted runs. Glass can load the rim and glaze the diamonds faster than you’d expect. A few quick passes restored bite each time. Over a backsplash and shelving project, I noticed a small but definite drop in aggressiveness after substantial linear footage; not abrupt, but enough to make me increase dressing frequency. That’s typical for a glass-specific continuous rim.

In terms of overall life, I’d categorize it as good for a premium glass blade—more than a one-project wonder, less than a general-purpose tile blade cutting porcelain. The dense diamond concentration seems to pay dividends in consistency: performance fades gradually rather than cliff-diving mid-project. Handling matters, too. Don’t dry cut with this blade, and don’t ask it to touch ceramic or porcelain. Use it for glass, keep it wet, and it should cover multiple glass jobs without drama.

Accuracy and edge quality

I measured flake size along the cut under a loupe on a few test pieces. The XP4 kept chips to specks rather than crescents, and most were on the exit edge where technique matters most. On back-painted glass, the paint stayed put—no lifting or flares—when I used a slow finish pass. On clear glass, the edge was uniformly frosted, not polished, which is what you want before any edge finishing. A couple of quick strokes with a fine diamond hand pad brought it to a touch-safe finish.

Miters on glass are always tricky. The XP4 managed them with light, repeated passes and tight support under the piece. If you plan a lot of miter work, expect to factor in extra time and frequent dressing to keep the rim sharp.

What it isn’t

This isn’t a universal tile blade, and that’s by design. It’s not intended for ceramic or porcelain, and it isn’t a dry-cut blade. If you need one blade to swing between materials, look elsewhere; the XP4 earns its keep by being very good at one job. Also note that the manufacturer doesn’t print an RPM rating on the spec card I saw. That’s common on 7-inch wet-saw blades, but it’s still up to you to run it on a saw within normal wet-saw speeds and keep feed pressure sensible. Let the diamonds do the work.

Practical tips for best results

- Dial in water: aim the nozzles directly at both sides of the cut and verify flow before you start.

- Support everything: add a sacrificial board under mosaics and small offcuts to reduce exit-chip.

- Slow the finish: lighten up in the last half-inch; it’s the easiest way to keep the exit edge clean.

- Dress periodically: a few passes on a dressing stone keeps the rim sharp and prevents glazing.

- Keep the saw true: check fence alignment and table wobble; glass magnifies minor errors.

Value

The XP4 sits at the premium end of the price spectrum for 7-inch glass blades. The question is whether the edge quality and predictability justify that cost. For me, on projects where the client will scrutinize every line of the backsplash under under-cabinet lighting, the answer is yes. If you’re doing a small, one-off project and can tolerate more cleanup on edges, a cheaper blade might “work,” but you’ll spend the savings on time and touch-up. The XP4’s advantage is fewer surprises and a higher percentage of keepers on the first pass.

Final thoughts and recommendation

The XP4 glass blade does what a glass-specific, continuous-rim blade should do: it cuts cleanly, tracks straight, and stays composed when the material gets brittle and the cuts get delicate. It rewards careful setup and patient technique, and it holds its performance if you keep it dressed and well-cooled. It isn’t a speed demon, and it isn’t a do-everything blade, but for glass tile and glass trim it delivers reliable, low-chip results.

I recommend it for pros and serious DIYers who need consistently clean edges on glass and have a properly tuned wet saw. If your expectation is one blade for every tile material, or you plan to dry cut, this isn’t the right pick. If your priority is finish quality on glass, the XP4 earns its place in the case.

Project Ideas

Business

Premium Glass Backsplash Specialist

Offer a glass-only backsplash service focusing on chip-free edges, tight miters, and fast one-day installs. Market the precision of continuous-rim wet cuts for upscale kitchens and baths where standard blades struggle with glass.

Pre‑Cut Glass Tile Kit Shop

Sell DIY mosaic kits (coasters, wall art, mirror frames) with pre-cut glass shapes, layout maps, and adhesives. The clean, consistent cuts reduce customer frustration and returns, and you can batch-produce shapes efficiently on a wet saw.

On‑Demand Glass Tile Cutting for Designers

Provide white‑label cutting services to tile showrooms and interior designers: listello strips, mitered trims, custom sizes, and tight tolerance parts. The blade’s low chipping enables premium finishes they can’t achieve in-house.

Hospitality Mosaic Commissions

Pitch chip-free glass mosaic feature walls and signage for restaurants, hotels, and spas. Use the blade for precise, repeatable cuts on large batches, enabling fast installation and consistent quality across multi-location projects.

Workshops: Cutting Glass Tile with Confidence

Host paid classes for contractors and DIYers on wet cutting glass tile, covering setup, feeds, taping techniques, and mitering. Monetize via tuition, material sales, and upsells to pre-cut kits or contract services.

Creative

Seamless Mosaic Mirror Frame

Cut glass tile into thin, consistent strips and tight 45° miters to build a chip-free, seamless frame around a mirror. The continuous-rim blade’s smooth wet cut keeps edges clean so grout lines stay razor-thin, giving a high-end, boutique look.

Backlit Glass Tile Light Panel

Create geometric patterns from glass tile (diamonds, triangles, chevrons) and mount them over a slim LED panel. The blade’s reduced vibration helps keep long, straight cuts true so light leaks are minimal and the design glows evenly.

Gradient Wall Art Mosaic

Slice glass tiles into uniform tesserae and arrange by color for an ombre mural on a wood or foam backer. The dense diamond concentration minimizes chipping on delicate, translucent pieces so the color gradient reads crisp and uninterrupted.

Custom Shower Niche with Mitered Trim

Miter glass tile edges on a wet saw to fabricate a picture-frame niche trim with glass-on-glass corners. The chip-free continuous rim keeps exposed miters clean so you can skip bulky profiles and maintain a seamless, all-glass look.

Modern Address or Name Plaque

Cut glass tile into precise letters or number segments using straight kerfs and assemble on a weather-resistant backer. The blade’s smooth cut preserves glossy edges for a sleek, contemporary plaque that stands out at entrances.