Features

- Down-spiral flute directs chips downward to reduce clogging

- Drill-through pilot for guided plunge and template work

- High-speed steel construction

- Reduces chipping and upward tearing of material

- Resharpenable cutting edge

- Sold individually

Specifications

| Cut Diameter | 1/4 in |

| Shank Diameter | 1/4 in |

| Flute Length | 0.675 in |

| Working Length | 5/8 in |

| Material | High speed steel |

| Suitable Materials | Aluminum sheets, wall panels, plywood, chipboard, insulation sheeting, synthetic boards |

| Product Dimensions | 2.75 in x 0.25 in x 0.25 in |

| Weight | 0.05 lb |

| Upc | 000346049015 |

| Pack Quantity | 1 |

| Regulatory Note | Prop 65: product can expose you to chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm |

Related Tools

Related Articles

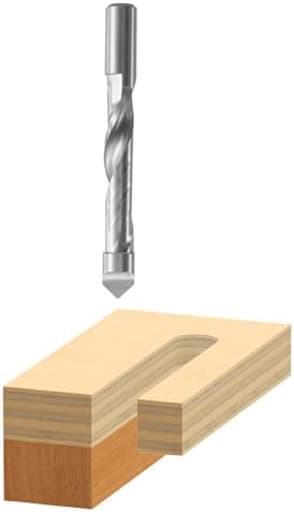

High-speed steel down-spiral router bit with a drill-through pilot point. The down spiral directs chips downward to reduce build-up and help prevent chipping and upward tearing of the workpiece. The pilot guides the bit for template or framing operations and the cutting edge can be resharpened for continued use. Intended for cutting thin sheets and panels and for window/door cutouts.

Bosch Pilot Panel Down Spiral Bit Review

Why I reach for this bit

Cutting clean openings in thin sheet goods can be maddening with the wrong cutter: the top veneer chips, the kerf clogs, and plunge starts wander. For window and door cutouts, outlet openings, and HVAC penetrations in plywood, paneling, and synthetic sheets, I’ve had good results with Bosch’s panel‑pilot downcut bit. It’s a straightforward tool—1/4-inch shank and 1/4-inch cut diameter, high-speed steel, down-spiral flutes, and a drill-through pilot point—but the details add up to a reliable, controllable cut in the materials it’s meant for.

Design and specs that matter

- 1/4 in cut diameter and 1/4 in shank, so it fits trim routers and full-size routers with a 1/4 in collet.

- Down-spiral flute that pushes chips downward.

- Drill-through pilot point for accurate plunge starts and template/framing guidance.

- HSS construction with a resharpenable edge.

- Flute length of 0.675 in and working length of 5/8 in.

On paper, that working length tells the story: this bit is tuned for thin sheets and panels. On 1/4 in to 1/2 in stock, the geometry feels right. If you routinely cut 3/4 in material, the 5/8 in working length becomes a real limitation; you either need to step your cut or choose a longer bit.

Setup and technique

I’ve used this mostly in a compact, fixed-base trim router at 22,000–28,000 RPM. The pilot point makes plunge starts easy: mark the opening, drill through with the bit itself, tip the router to engage, and then feed into the cut. The pilot rides along an existing opening, framing members, or a template. Because there’s no bearing, your template must define the finished edge; there’s no built-in offset to account for.

A few practices that improved my results:

- Keep the base flat and maintain steady pressure against the template or framing; the pilot is forgiving, but you can push it off line with inconsistent pressure.

- Vacuum or blow out the chips periodically. Downcut flutes keep the top face clean, but they pack chips below if you don’t evacuate them.

- For laminate-faced panels, blue tape plus a light scoring pass before full-depth routing further reduces top-side chipping.

- Move clockwise when cutting inside openings to maintain constant support at the edge.

Cut quality in plywood, paneling, and synthetics

On cabinet-grade plywood and wall paneling, the top surface stayed noticeably cleaner than with an upcut panel-pilot bit. The down-spiral puts the cutting pressure down into the work, so I didn’t see the familiar fuzzing and chip-out along the top veneer. The pilot point leaves a small center hole where you start; in most cutout applications that hole ends up inside waste.

Edge quality depends on feed rate and sharpness. HSS arrives quite sharp; if you push too slowly and let chips accumulate, you’ll get heat and a slight burnish on resin-heavy plies. With a brisk, steady feed and chip extraction, edges were crisp and ready for paint or trim. On melamine and high-pressure laminate, the top face stayed intact—better than many carbide straight bits—but HSS dulls faster in those abrasive materials, so I reserve this for short runs or fieldwork, not for production in melamine.

One trade-off with any downcut: the underside can chip as the cutter exits. Backer material solves this. When I could, I clamped a sacrificial board; otherwise, a climb pass taking 1/32 in before the final conventional pass helped minimize breakout on the back face.

Aluminum sheet capability

Bosch lists aluminum sheets as a suitable material, and I’ve used this bit on thin 3003/5052 sheet for panel openings. A few caveats:

- Use light passes and keep the router square; aluminum will let the pilot skate if you plunge aggressively.

- A dab of cutting wax or a spritz of WD‑40 on the flutes reduces galling and heat.

- Clear chips often; downcut flutes will push them into the workpiece cavity, which is fine if the cavity is open but can pack tightly in closed pockets.

Edge finish wasn’t mirror-smooth (it’s a router cut on thin aluminum), but it was clean and burrs were minimal—quick deburr with a countersink took care of it. I would not use this on steel or thick aluminum plate.

Dust and chip management

Directing chips downward is a two-edged sword. Overhead or vertical work benefits because chips aren’t blasting back at you, and the top face stays clean with less scoring. The flip side is that you’re packing chips where you can’t always see them. In hollow wall cavities or door panels that’s fine, but in closed boxes I paused to vacuum often. If you have a router base with decent dust collection, connect it; it makes a noticeable difference in cut temperature and edge polish.

Durability and maintenance

High-speed steel is resharpenable and takes a keen edge. In my shop, edge life was good in plywood, MDF, and synthetic boards for light to moderate work. On melamine or highly filled composites, it dulls faster than carbide—no surprise there. The good news is that the geometry is straightforward to touch up: a light grind on the cutting lips brings it back. If you’re routing hundreds of openings in abrasive sheet goods, a carbide compression panel-pilot would be the better long-term buy. For installers and occasional shop use, the HSS bit hits a sweet spot of cut quality and cost.

Where it shines

- Field installs: trim routers, ladder work, and awkward positions where a clean top surface matters and a pilot helps you stay on line around framing.

- Window, door, and vent cutouts in plywood sheathing, paneling, and synthetic sheets.

- Template routing of openings where a bearing would be impractical or add offset.

The pilot point genuinely simplifies life in those scenarios. I’ve done similar work with spiral bits and a pre-drilled starter hole; the pilot is quicker and more confident, especially when visibility is poor.

Limitations and caveats

- Working length is 5/8 in. That’s great for panels up to 1/2 in; marginal for 5/8 in; not ideal for 3/4 in.

- The pilot is not a bearing; it won’t tolerate nails, staples, or screws. Find and remove fasteners first.

- Downcut means more heat if you baby the cut. Keep your feed up, and clear chips.

- Not for ferrous metals. Light aluminum only, with lubrication.

Also note the Prop 65 warning common to many cutting tools; store and handle in line with your shop’s safety practices.

Alternatives and how this compares

Compared to an upcut panel‑pilot bit, the Bosch downcut version gives better top-face results and a slightly quieter cut, at the cost of more attentive chip clearing. Against a compression-style pilot bit (up/down flutes), the compression wins on two-sided laminate and thicker stock, but it’s heavier, pricier, and less happy in very thin material. A bearing‑guided laminate trimmer bit is great when the template can set standoff; here, the pilot’s zero-offset guidance is the advantage.

Practical tips

- Run 20,000–28,000 RPM on a trim router with a steady feed; don’t linger.

- Use a sacrificial backer when the back side matters.

- Score laminate or veneer for absolutely pristine edges.

- Keep a small file or deburring tool handy for aluminum edges.

- Mark and probe for fasteners before plunging the pilot.

Recommendation

I recommend the Bosch panel‑pilot downcut bit for anyone who regularly needs clean, guided cutouts in thin sheet goods—installers, cabinet shops, van upfitters, and remodelers. It produces a tidy top edge, the pilot makes plunge starts and template work simple, and the HSS edge is sharp and resharpenable. Its 5/8 in working length and HSS wear rate limit it for thick or highly abrasive materials, so high-volume laminate work is better served by a carbide compression alternative. But for its intended role—window and door openings, outlet cutouts, and panel work in 1/4–1/2 in stock—it’s a dependable, no-fuss choice that’s earned a place in my trim router kit.

Project Ideas

Business

Mobile Van/RV Cutout Service

Offer on-site window and vent cut-ins for vans, RVs, and tiny homes, using template-guided routing in aluminum skins and wall panels. The down-spiral bit preserves exterior finishes, reducing touch-up and seal prep. Package with gasket install and trim finishing.

Decorative Panel Studio

Produce custom wall, ceiling, and privacy panels in plywood, chipboard, or synthetic boards with branded patterns. The pilot-guided bit speeds template production for consistent runs without top-face tear-out. Sell ready-to-install panels to interior designers and builders.

Custom Electronics Faceplates

Make low-volume aluminum and plastic faceplates with clean switch, display, and connector cutouts. Use jigs and templates for repeatable results; the down-spiral minimizes edge chatter on the visible side. Offer engraving, powder-coat, and fast turnaround.

Door/Window Retrofit Partner

Partner with shed and ADU builders to handle precise window and door cutouts in pre-assembled wall panels. Create reusable templates for common sizes; the pilot point speeds plunge starts and corner accuracy. Bill per opening with optional trim routing and sealing.

Template & Jig Product Line

Design and sell acrylic templates for vents, hatches, speakers, and utility cutouts optimized for pilot-point bits. Bundle with setup guides and clamps, targeting DIYers and contractors. Offer custom logo patterns for boutique builders and makerspaces.

Creative

Layered Topographic Map Art

Stack contour layers cut from thin plywood or synthetic boards using a set of templates. The down-spiral bit keeps the top veneer crisp while the drill-through pilot lets you plunge and follow each template cleanly. Finish with stains/paints for elevation contrast and mount in a shadow frame.

Mid-Century Perforated Room Divider

Create a freestanding divider from thin plywood or chipboard with repeating hole and slot patterns. The downcut flutes prevent chip-out on the show face, and the pilot point rides template guides for fast, repeatable motifs. Edge-band and clear-coat for a furniture-grade look.

Aluminum Lantern Lightbox

Cut decorative window patterns and ventilation slots in thin aluminum sheets for a modern lantern. The pilot helps start precise plunge cuts inside the panel, and the down-spiral minimizes burrs on the visible side. Back the cutouts with frosted acrylic and LEDs.

Camper Window Upgrade

Add a custom acrylic window to a teardrop trailer or tiny shed. Use a template to route the opening in exterior panels without splintering the outer veneer, then follow up with a matching trim-ring template for a professional fit.

Acoustic Slotted Wall Panels

Route elongated slots in plywood or laminate-faced panels to create attractive, sound-absorbing wall features. The down-spiral protects the face veneer, while the pilot point tracks slot templates for consistent spacing. Back with black felt for a clean, dimensional look.