Features

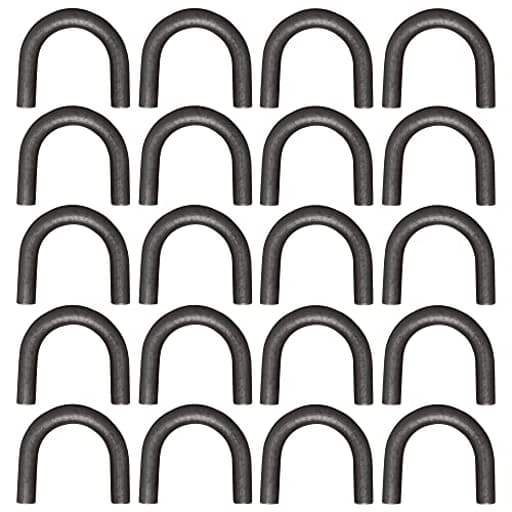

- 20 Pack of D-Ring Tie Downs

- Great for chains, heavy duty straps on trucks and trailers as well as other applications

- Can be used wherever a rope-tie or halter-tie is needed, easy weld-on style

- Made from durable, heavy duty 1/2" alloy steel

- Inside Diameter: 2" - Outside Diameter: 3"

Specifications

| Size | 3 inches x 0.5 inches |

| Unit Count | 20 |

Pack of 20 weld-on steel D-ring tie downs for securing chains, straps, ropes, and halters on trucks, trailers, and other equipment. Each D-ring is made from 1/2" thick alloy steel and measures 2" inside diameter and 3" outside diameter with a weld-on base for permanent attachment.

A.A 20 Pack 1/2" Thick Weld-on Steel D-Ring Rope Hook Chain Tie Down D Ring for Trucks Trailers Review

What I used and why

I needed a simple, permanent way to add more tie-down points to a small equipment trailer and a couple of steel posts in my carport. Bolt-on anchors would have worked, but the locations I had in mind were better suited to welding. I picked up this 20‑pack of weld‑on D‑rings to knock out both projects and leave spares for future builds. Each ring is 1/2-inch thick alloy steel with a 2-inch inside diameter and a 3-inch outside diameter, attached to a flat weld-on base. The size is a sweet spot: big enough to accept typical chain hooks, strap ends, and carabiners, but not so bulky that they snag everything in the bed.

Build and finish

Out of the box, the D‑rings are no-nonsense steel parts. Mine arrived with a light oil to keep rust at bay and a few cosmetic scuffs from shipping—nothing that matters once you grind, weld, and paint them. The rings were consistent in thickness and shape; the inside diameter was uniform, and the bases sat flat on plate and tubing without rocking. I measured several with calipers, and they were right on spec. No weird cast flashing, pits, or out-of-round oddities to deal with.

The 1/2-inch cross-section feels stout in hand, and that thickness pays off when you’re working with hooks and chain. Standard 3/8-inch transport chain hooks nest comfortably, and 2-inch strap hardware drops through the opening without fighting for space. The weld-on pad is sized sensibly: enough footprint to lay in a proper fillet weld without crowding the ring.

Welding and installation

These D‑rings weld the way you want them to. I installed eight along each side of a trailer’s 3/16-inch angle rail and a pair on 4x4 steel posts in a carport. Prep was straightforward: I hit the surfaces with a flap disc to clean off mill scale and paint, wiped everything with acetone, and clamped each ring in place. I oriented the ring so the opening faces down when used for tie-down—this helps the load seat in the curved portion rather than prying on the open end.

Welding was with ER70S‑6 wire, C25 gas, about 19–20 volts and 250–275 ipm for the trailer, stepping up for the thicker post install. On the thinner rail, I used a two-pass fillet to avoid overheating the base metal; on the posts, a single heavier pass was fine. If you’re stick welding, 7018 at the appropriate amperage will do a nice, clean job. In all cases, the rings took heat well, wet out nicely, and didn’t spit contaminants back into the puddle. No surprises—just good, weldable steel.

A few practical notes:

- Put these on structure, not on sheet. Aim for frame rails, crossmembers, or tube posts.

- Space them so your ratchet handles have room to operate; I went about every 18–24 inches.

- Watch alignment: keep the ring plane vertical to minimize side loading.

- After welding, prime and paint right away. The ring shape traps moisture if left bare.

Performance under load

I’ve used the trailer anchors for a half-dozen trips so far: a compact lawn tractor, stacks of 2x lumber, and a load of pavers. The rings haven’t budged, and the weld toes show no cracking or rust creep after use in light rain. The 2‑inch ID comfortably accepts strap hooks without marring the zinc plating, and there’s enough material thickness that chain links don’t bite into an edge.

On the carport posts, I hung a sit-on-top kayak with rope slings and added two rings low on the leeward side to clip in shade panels. The rings don’t squeak or rattle once painted, and the low-profile base keeps them from snagging clothing. For hanging and light rigging, they’re unremarkable in the best way: you forget they’re there because they just work.

It’s worth pointing out that these are not stamped with a working load limit. The actual capacity in service is a combination of the ring, the weld size and quality, and the base metal you attach to. For non-commercial use—trailers, home rigs, utility hauling—they’re more than robust enough when welded correctly. If you need rated anchor points to meet DOT or workplace requirements, look for stamped, certified hardware and follow the manufacturer’s weld procedures.

Versatility

The form factor makes these handy beyond trailers:

- Shop and garage: overhead rope guides, quick clip-in points for slings (with proper structure).

- Vehicle racks: low-profile anchors for strap tie-downs (again, welded to structure).

- Yard projects: gate latches, tether points, or shade sail corners on steel posts.

Because they’re a permanent weld-on, you don’t have hardware loosening over time, and you’re not drilling holes that can crack paint and invite rust in thin sheet metal.

Things to watch

- Permanent means permanent. Plan your layout carefully; grinding off a well-welded ring is no fun.

- Weld quality matters. A burly ring won’t save a cold lap or an undersized fillet. If you’re unsure, have a welding-savvy friend or shop handle the install.

- No swivel. For loads that shift, these can put a twist on straps. Swivel rings or recessed swivel anchors are better for that.

- Clearance. The 3-inch outside diameter is fairly compact, but give yourself room around stake pockets, fenders, and jack handles.

- Rust protection. After welding, prime with a zinc-rich primer and topcoat. Touch up chips early; rings tend to see chain and hook abrasion.

How they compare

Against bolt-on tie-downs, these D‑rings win on robustness and simplicity once installed. No nuts to loosen, no backing plates to fuss with. They lose on flexibility—bolt-ons can be removed or relocated. Compared to E-track systems, you don’t get modularity, but you do get a much stronger single-point anchor with less protrusion. If you need flush floors, recessed D‑rings are a better choice, but they require cutting and reinforcing the deck. For most utility trailers and steel frames, these weld‑on rings are a strong, low-cost, minimal-hassle solution.

Tips for best results

- Surface prep matters. Grind to bright metal on both parts; clean with solvent before striking an arc.

- Size your weld to the job. For 1/8–3/16-inch trailer rails, a multi-pass fillet reduces burn-through risk.

- Orient thoughtfully. A downward-facing opening seats hooks well and sheds water after rain.

- Think chains and straps. The 2-inch ID accommodates most hook styles; test-fit your hardware before final placement.

- Finish like you mean it. Prime and paint every ring and the surrounding weld area; toss a spare can in the trailer for touch-ups.

The bottom line

These weld‑on D‑rings do exactly what they’re supposed to do: provide sturdy, compact anchor points that are easy to install and hold up under repeated use. The steel is cooperative under the torch, the dimensions are true, and the size works with the most common strap and chain hardware. You give up adjustability and a stamped load rating, and you’ll need to bring welding competence (or someone who has it). In return, you get durable, low-profile anchors that should outlast the trailer or post they’re welded to.

Recommendation: I recommend these D‑rings for anyone comfortable with welding who wants permanent, reliable tie-down points on steel trailers, racks, or posts. They’re affordable in bulk, consistent in quality, and straightforward to install. If you require rated hardware for commercial compliance, or you need removable anchors, look elsewhere. For general hauling and shop rigging on steel structure, these are a solid, no-drama choice.

Project Ideas

Business

Mobile Tie‑Down Installation Service

Offer on-site welding and installation of permanent D-ring tie-downs for trucks, trailers, RVs and farm equipment. Market to small fleets, landscapers, haulers and recreational customers. Revenue streams: per-unit installation, fleet contracts, emergency mobile service. Low startup: welder, trailer, parts stock.

DIY Tie‑Down Kits (E‑commerce)

Package the D-rings with welded mounting plates, grade-8 bolts, step-by-step instructions and optional mounting templates to sell as plug‑and‑play kits for DIYers. Target channels: Amazon, Etsy, niche forums for overlanders, boaters and tiny-home builders. Upsells: stainless options, pre-drilled plates, installation video downloads.

Industrial Home Decor Product Line

Create a branded line of industrial-style home goods using welded D-rings: coat racks, curtain tiebacks, shelving anchors, and lamp hangers. Produce small batches and sell on Etsy, at craft fairs and to boutique home stores. Differentiators: genuine heavy-alloy hardware (not flimsy replicas) and customizable finishes.

Fleet Compliance & Retrofit Packages

Package inspection, retrofitting, and documentation services for small-business fleets to meet cargo restraint/safety standards. Offer site surveys, install certified D-ring anchor points, provide load‑testing certificates and recurring maintenance. Sell as annual subscriptions to landscapers, movers and construction contractors.

Creative

Industrial Coat & Gear Rack

Weld several D-rings onto a reclaimed wood board or flat steel plate to create a heavy-duty wall-mounted rack for coats, backpacks, helmets and tool belts. The 1/2" alloy steel rings take heavy loads and give an industrial look—finish with a clear coat or patina. Variations: staggered rings for different heights, add numbered plates for workshop organization.

Modular Hanging Planter Grid

Build a steel frame (or repurpose a pallet) and weld D-rings at regular intervals to serve as anchor points for rope-hung planters. Use the rings to change planter positions easily or to loop different rope lengths. Great for vertical herb gardens on patios or balcony screens; rings make planting reconfiguration simple.

Heavy-Duty Pet Tie-Out Station

Create a secure, permanent pet tie-out system for decks, porches or yards by welding D-rings to steel posts or mounting plates. Combine with quick‑release carabiners and braided rope/straps to make a weatherproof tether point that’s safer than temporary stakes. Offer versions sized for dogs, horses, or multiple pets.

Secure Cargo Bench / Garage Storage

Fabricate a garage or truck-bed bench with welded D-rings on the top and sides so gear can be strapped in place. Use internal storage for tools and external D-rings for straps to secure bikes, fuel cans, or power equipment. Ideal for entryway benches too—baskets clip to rings for flexible storage.