Features

- Zirconia-based abrasive grain for extended wheel life

- High grain concentration for aggressive material removal

- Type 27 (raised hub) wheel profile for grinding applications

- Three full sheets of fiberglass reinforcement for increased durability and safety

- Designed for smooth running in compatible angle grinders

Specifications

| Product Diameter | 4-1/2 in |

| Disc Thickness | 1/8 in |

| Arbor Size | 5/8"-11 |

| Number Of Pieces | 25 |

| Product Pack Quantity | 25 |

| Includes | Cutting and grinding wheel (individual); sold in packs of 25 |

| Warranty | Not eligible for warranty (no limited warranty) |

Related Tools

Related Articles

Type 27 ceramic cutting and grinding wheels intended for cutting and grinding metal and stainless steel. The wheels use zirconia-based abrasive grain and are reinforced with multiple layers of fiberglass for durability and improved safety during use. They are designed for sustained material removal and smooth running in compatible grinders.

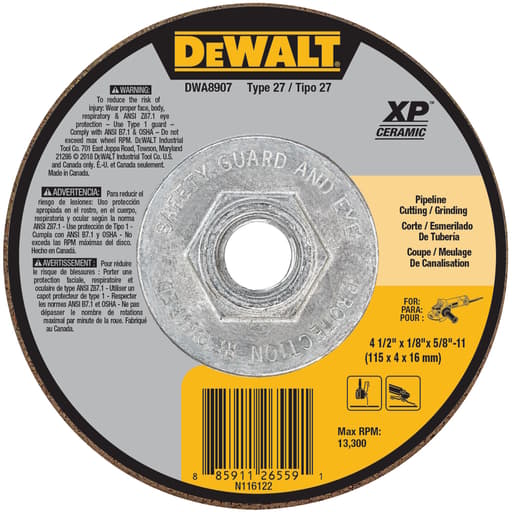

DeWalt 4-1/2" x 1/8" x 7/8" Ceramic Metal & Stainless Cutting & Grinding Review

I keep a stack of 4-1/2-inch combo wheels on the shop shelf, and lately the one I reach for most is DeWalt’s Type 27 1/8-inch cutting/grinding wheel. It’s a simple, humble accessory, but the right abrasive changes how a grinder feels in your hands. This wheel has the balance, life, and control I want when I’m bouncing between cutting and light cleanup on steel and stainless.

Setup and Compatibility

This wheel is a Type 27 (raised hub), 4-1/2-inch diameter, 1/8-inch thick, with a 5/8"-11 threaded arbor. On my grinders that means it threads straight onto the spindle without fuss, sits flush, and runs true. No drama with the flange. If you’re used to flat cutoff wheels with a 7/8-inch arbor that rely on a nut, the threaded hub is a nice quality-of-life improvement—especially if you’re swapping wheels often on site.

It’s a 1/8-inch “combo” profile, so it’s thick enough to handle side pressure for light grinding and beveling, but still thin enough for straight, controlled cuts. I use it primarily with mid-size, 10–13 amp corded grinders and 18V/20V cordless grinders. Just verify the RPM rating on the label and keep your guard in place; this wheel is sized for the common 4-1/2-inch class, so compatibility hasn’t been an issue.

Build and Safety

The construction is what you’d expect from a wheel that leans toward pro use. The abrasive is a zirconia-based blend (often marketed as “ceramic” or “zirconia alumina”), which is tougher and more self-sharpening than the cheaper aluminum oxide wheels you find in bargain packs. Under pressure, zirconia fractures to expose fresh cutting edges rather than glazing over—exactly what you want when you’re cutting stainless or leaning into welds.

DeWalt uses three full sheets of fiberglass reinforcement in this wheel. I don’t get overly romantic about reinforcement layups, but in use it translates to stability and a little extra confidence when a cut binds or you accidentally tip the wheel into a bead. It runs smooth, without chatter, right up to the last usable inch. For storage, bonded abrasives carry expiration dates; the stock I’ve received has had plenty of runway left. Keep them dry and out of the back of the truck bed if you can help it.

Cutting Performance

For a 1/8-inch wheel, it cuts cleanly and predictably. I’ve used it to trim galvanized fence posts, slice rusted bed bolts off a truck frame, and section 3/8-inch plate for brackets. On stainless tube and sheet, it notably resists loading and keeps the cut temperature down compared to basic AO wheels. You can still discolor stainless if you lean too hard or linger, but if you let the wheel do the work you’ll see a steady stream of bright, fine sparks and a kerf that doesn’t scorch the edges.

Compared to a dedicated 0.045-inch cutoff, this wheel won’t win the race for fastest, coolest cut—that’s not its brief. The extra thickness means a wider kerf and slightly more heat. But you get consistency, durability, and the ability to transition from cut to quick cleanup without swapping wheels. On site, that matters more than shaving a few seconds off a cut.

A few practical notes:

- Rebar and structural steel: Straight cuts are quick and repeatable. I find it happiest at moderate pressure; too light and it skates, too heavy and you lose that self-sharpening effect.

- Stainless fasteners and thin-wall tube: Good control and minimal grab. Keep your angle shallow and your feed steady.

- Aluminum: It’ll cut, but aluminum can load any bonded wheel. A quick swipe of cutting wax or a dedicated non-ferrous wheel is better. If this is your only wheel on hand, ease off periodically to clear the face.

Grinding and Cleanup

The Type 27 profile and 1/8-inch thickness make this a capable “one wheel to finish the task” when you’re doing light grinding, beveling edges for weld prep, or knocking down a small bead. It’s not a substitute for a 1/4-inch grinding wheel or a flap disc when you need to move a lot of material or blend for finish, but it tolerates side loading within reason.

I like it for:

- Breaking sharp edges after a cut

- Beveling a small chamfer before welding

- Cleaning up a tack or a small booger weld in a tight corner

Hold it around 10–15 degrees to the work and use controlled, short passes. Compared to thin cutoffs, it’s far less prone to chatter or digging in when you turn the wheel to the side.

Life and Value

Durability is where this wheel separates itself from the cheap stuff. The zirconia grain maintains bite longer, so I spend less time muscling a glazed wheel through steel. On a job that mixes cutting and light grinding, I can run one wheel for several tasks instead of swapping to a fresh cutoff and then to a flap disc. Over a full day of miscellaneous shop work, that adds up to fewer changes and a steadier pace.

Is it the longest-lasting wheel I’ve ever used for pure cutting? No—a dedicated thin-kerf ceramic cutoff will outpace it on straight cuts per wheel. But as a general-purpose metal wheel that straddles cutting and grinding, the life is excellent, and it stays safe and stable as it wears down.

Sold in a 25-pack, it’s well suited for a shop that wants consistency across stations or for stocking a job box. There’s no meaningful “warranty” on consumable abrasives, which is standard; what matters is the quality of the cuts and the confidence that the wheel won’t come apart under normal use. On both counts, this wheel is solid.

Limitations

- Not the fastest for thin-stock cutting: If you only need to make quick, cool cuts in sheet or tubing, a 0.045-inch wheel is faster and gentler on the material.

- 4-1/2-inch size disappears on big work: If you’re cutting a lot of heavy stock, stepping up to a 6-inch grinder and wheel saves time and reduces changeovers.

- Aluminum and non-ferrous: It’ll work in a pinch, but it can load. Use wax or pick a wheel designed for non-ferrous metals.

None of these are knocks against the wheel so much as natural tradeoffs of the format and thickness.

Tips for Best Results

- Let the wheel cut. Moderate, steady pressure keeps zirconia sharp and the cut straight.

- Keep the guard on and watch your angle. Even with triple reinforcement, side-loads can snap any bonded wheel if abused.

- For stainless, avoid excessive pressure to reduce heat tint and reduce your rework.

- If you need to switch from cut to grind, let the wheel spin free for a moment to clear fines before tipping it into the work.

- Store wheels flat and dry. Check the expiration date stamped on the label and rotate your stock.

Recommendation

I recommend this DeWalt wheel as a dependable, versatile 4-1/2-inch option for anyone who needs one wheel to handle both cutting and light grinding on steel and stainless. The zirconia grain holds its bite, the triple reinforcement keeps it running smooth and secure, and the Type 27 profile makes it practical to cut, chamfer, and clean up without a swap. If your work is mostly straight, thin-kerf cuts, go with a dedicated 0.045-inch cutoff. If you’re tackling mixed tasks around the shop or jobsite and want fewer wheel changes with longer, steadier performance, this wheel earns its place in the grinder bag.

Project Ideas

Business

Custom Metal Signage & Address Plates

Offer house numbers, business logos, and wayfinding signs in steel or stainless. Use the wheels to cut, contour, and brush surfaces for a premium finish. Sell standard sizes online and provide local installation for custom projects.

Mobile On‑Site Cutting & Deburring

Provide a same-day service to trim bolts, cut openings, and deburr edges on job sites, restaurants, and warehouses. The durable zirconia wheels enable fast, clean cuts on structural steel and stainless fixtures with predictable costs thanks to 25-pack bulk.

Handrail and Guard Fabrication

Fabricate and install steel or stainless handrails, grab bars, and guard panels. Use the wheels to miter tubing, prep joints, and blend welds to a consistent finish. Offer code-compliant measurements, templates, and powder-coat or brushed stainless options.

Restaurant Stainless Solutions

Build custom shelves, splash guards, smoker baffles, and griddle tools for commercial kitchens. The grinding wheels help deliver smooth, sanitary edges and blended welds. Package services with on-site measurement and quick-turn fabrication.

Weld Cleanup and Finishing Service

Partner with local welders and small fab shops to handle grinding, blending, and edge radiusing on parts. Per-piece pricing and pickup/delivery make it easy for shops to outsource finishing while you leverage the wheel’s aggressive material removal for throughput.

Creative

Upcycled Flatware Garden Sculpture

Turn discarded stainless spoons, forks, and knives into flowers, insects, or abstract forms. Use the 4-1/2 in Type 27 wheel to cut stems and petals from flatware and thin sheet, then grind welds smooth and add brushed textures that catch the light.

Industrial Skyline Wall Art

Cut city skyline silhouettes or mountain ranges from sheet steel or stainless. The zirconia abrasive gives clean cuts and fast stock removal for beveling edges, while the raised hub profile helps you blend seams and add layered depth before clear-coating or blackening.

Geometric Metal Planters

Fabricate faceted planters from mild steel or stainless offcuts. Score and cut panels with the wheel, weld, then use the grinder to break edges, radius corners, and create a uniform brushed finish. Great for indoor succulents or outdoor garden accents.

Custom Fire Pit Accessories

Make spark guards, grill grates, and poker sets. The wheel handles stainless rods and flat bar for food-safe components, and can quickly dress welds so accessories look clean and professional.

Gear Lamp or Bike-Chain Clock

Cut a circular backing plate, mount reclaimed gears or bike chain links, and grind highlights for contrast. Finish with a clear coat to showcase industrial textures in functional home decor.