Features

- Aluminum oxide grain formulation for extended life on aluminum and other soft metals

- Soft resin bond to help prevent loading and enable faster material removal

- Three layers of glass reinforcement for added durability and safety

Specifications

| Product Type | Depressed center wheel (Type 27) |

| Abrasive Material | Aluminum oxide |

| Applicable Material | Aluminum and other non-ferrous metals |

| Bond Type | Resin (resinoid) |

| Wheel Diameter | 4 in (family includes other diameters) |

| Wheel Thickness | 1/4 in |

| Center Hole Size | 5/8 in |

| Grit | 30 (very coarse) |

| Wheel Hardness | N |

| Maximum Speed | 15,200 rpm |

| Connector Type | Arbor |

| Grade | Very coarse |

| Standards | ANSI specified |

| Wheel Color | Black, yellow |

| Package Quantity | 25 (varies by SKU) |

Related Tools

Related Articles

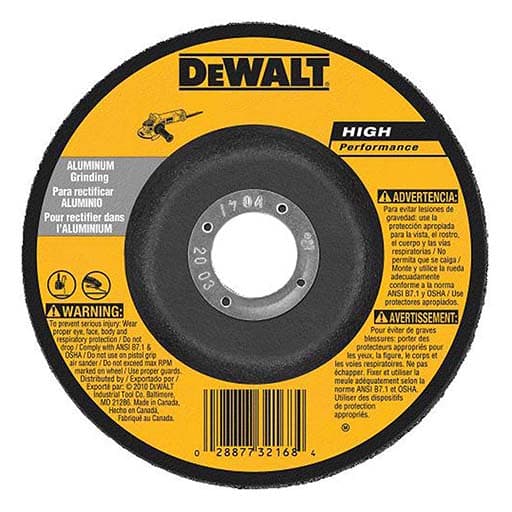

Type 27 depressed-center grinding wheel intended for grinding aluminum and other non-ferrous metals. Constructed with aluminum oxide abrasive and a resin bond to provide material removal while resisting loading.

DeWalt HP Aluminum Grinding Wheel Type 27 Review

Why I reached for this wheel

Aluminum can turn a standard grinding wheel into a glazed hockey puck in minutes. Between smearing, loading, and heat, it’s a material that demands a wheel made for the job. I’ve been running DeWalt’s aluminum-focused Type 27 wheel—the DW8400—on a compact grinder for weld cleanup, beveling, and general stock removal on 6061 and 5052. It’s a straightforward, coarse, depressed-center wheel with a soft resin bond and aluminum oxide grain, built specifically to keep loading at bay while staying aggressive. Over several weeks of fabrication work, it showed a good balance of cut rate, control, and durability for aluminum and other non‑ferrous jobs.

Build and specs that matter

The DW8400 I tested is a 4-inch diameter, 1/4-inch thick Type 27 with a 5/8-inch arbor, rated to 15,200 rpm. It’s a very coarse 30-grit wheel with a medium-soft bond (marked N), reinforced with three layers of fiberglass. In hand, it feels like a true grinding wheel rather than a multi-purpose disc—thick, slightly compliant at the edges, and clearly intended for grinding on the face at a shallow angle rather than on the rim like a cutoff wheel.

A few quick notes that affected my use:

- Type 27 depressed-center geometry plays nicely with a grinder guard and keeps the wheel stable at 15–25 degrees.

- The soft resinoid bond is key for aluminum; it sheds grain to prevent loading and self-sharpens under pressure.

- 30 grit is unapologetically coarse. Think weld removal, beveling, and heavy deburring—not blending to a cosmetic finish.

Setup and balance

Out of the box, the wheel ran true. No noticeable hop, no odd vibration at speed, and balance stayed consistent as the diameter wore down. I mounted it on a 10,500 rpm grinder (well below the wheel’s 15,200 rpm limit) with a Type 27 guard. After a brief one-minute no-load spin-up to check for issues, I went straight to work on 6061-T6 plate and square tube.

Performance on aluminum

The reason to use a wheel like this is simple: avoid loading while keeping the cut moving. In practice, that’s what I saw.

Weld cleanup: I knocked down 1/8-inch proud fillet welds along a dozen 8–10 inch runs. The wheel stayed open and biting under moderate pressure. Keeping a 15–20 degree angle with a steady feed produced predictable, controllable grinding with less of the gummy “skate” you get from general-purpose wheels. I only needed to pause and brush the face once when I pushed too flat and too hard on a warm part.

Beveling and edge prep: On 1/4-inch 6061 plate, I cut a 1/16–3/32 chamfer along several feet of edge. The wheel held its corner well enough to do consistent prep without gouging. As long as I kept the tool moving and let the bond self-sharpen, I didn’t see the alloy smear that usually telegraphs into the surface.

Deburring: For trimming extrusions and plate cut on a shear, the wheel is admittedly more aggressive than necessary. It works, but you’ll leave a 30-grit texture that requires a flap disc pass if appearance matters.

Compared with a standard steel-focused grinding wheel, the DW8400 loads far less on aluminum. Compared with flap discs, it removes material faster, especially on weld toes and proud beads. The trade-off is finish quality; you won’t get a blended surface here.

Loading and heat behavior

No aluminum wheel is immune to loading. The question is how controllable it is. With light to moderate pressure, the DW8400’s soft bond kept the face open. If I got greedy—flattening out the angle or leaning hard to speed things up—I could glaze a section in a minute or two. A quick touch with a stainless wire brush or a dressing stick restored the cut. Using a stick lube (wax) improves things further, though I did most of my testing dry to judge the bond on its own. Heat discoloration on the workpiece was minimal (aluminum conducts heat quickly), but I still recommend light passes and an active feed to keep the wheel slicing rather than rubbing.

Wear and lifespan

Durability is solid for a soft-bond aluminum wheel. After the weld removal and beveling described above, the 4-inch wheel had lost approximately 3/16 inch of diameter—reasonable given the 30-grit aggression. I didn’t experience chunking, edge crumbling, or unexpected glazing. The three-layer reinforcement adds confidence when you need to lean into it, and the wheel stayed intact and predictable down to about 3-1/2 inches.

If you’re coming from flap discs, expect to use fewer of these wheels for heavy removal, but you’ll still want a flap disc on hand to refine the finish afterward.

Control and feel

What stood out is how controllable the wheel feels once you find the sweet spot. At 15–25 degrees and with firm, not frantic pressure, it tracks cleanly along welds without dancing or biting too deep. The depressed center and 1/4-inch thickness keep it from flexing into the work, so you can carve precisely when beveling or flattening a bead. Noise and vibration are typical for a coarse grinding wheel; hearing protection and a steady grip are a must.

Safety and good habits

- Use a Type 27 guard and mount the wheel per the grinder’s manual.

- Let the wheel run up to speed for 30–60 seconds before grinding.

- Aluminum dust is combustible; keep sparks and dust away from ignition sources and use extraction when possible.

- Don’t cross-contaminate: keep this wheel off ferrous metals to avoid embedding particles that can rust or spark later.

- Store resinoid wheels dry and cool; avoid using cracked or expired wheels.

Where it excels

- Fast weld removal on aluminum and non-ferrous alloys

- Beveling edges for prep before welding

- General stock removal where finish isn’t the priority

- Situations where general-purpose wheels quickly load up

Where it falls short

- Blending and finishing work—30 grit leaves a rough surface

- Thin sheet, where a flap disc offers better control and less risk of gouging

- Users who prefer one-disc-does-it-all; this is a task-specific wheel

- Cutting—at 1/4-inch thick, it’s strictly for grinding, not slicing

Buying advice and setup tips

- Match size and arbor to your grinder; the wheel family includes multiple diameters. Stay within the rpm limit.

- Run it at a consistent 15–25 degree angle; avoid flattening out under heavy pressure.

- Keep the face clean with a wire brush or a light dressing pass if you notice smearing.

- If you grind a lot of aluminum, consider a light wax stick to further reduce loading.

- Follow up with a 60–80 grit flap disc if you need a presentable finish.

Verdict

The DeWalt aluminum wheel does what I want a dedicated non-ferrous grinding wheel to do: resist loading, stay aggressive, and remain predictable under a reasonable hand. It’s not a finishing tool and doesn’t pretend to be; it’s a coarse, durable grinder for aluminum that rewards good technique and keeps the work moving without turning into a glazed puck.

I recommend it for fabricators, installers, and DIYers who regularly need to remove aluminum welds, prep edges, or take material down quickly without constantly fighting a loaded wheel. If your work leans heavily toward blending and surface prep, pair it with a flap disc. If you mostly grind steel, pick a wheel designed for ferrous metals instead. For its intended role—fast, controlled grinding on aluminum—the DW8400 is a dependable choice.

Project Ideas

Business

Mobile Aluminum Weld Cleanup

Offer on-site weld bead blending and edge-smoothing for contractors and fabricators working on aluminum handrails, storefront framing, truck boxes, and fixtures. The Type 27 wheel’s aluminum-oxide grain and soft resin bond reduce loading on soft metals, enabling fast, clean finishes with fewer wheel changes.

CNC/Waterjet Parts Deburr Microshop

Partner with local shops to pick up batches of router- or waterjet-cut aluminum parts and return them deburred with blended tabs and uniform edge breaks. The 30-grit, high-RPM-capable wheel excels at rapid stock removal, letting you price competitively and offer tiered finish levels with quick turnaround.

Marine and Trailer Accessory Refurb

Specialize in refurbishing aluminum toolboxes, ladder racks, trailer fenders, and boat accessories: remove gouges, blend corners, and prep for polish or coating. Leverage the wheel’s loading-resistant bond for efficient cleanup of oxidized or contaminated aluminum, then upsell protective finishes.

Grind-Texture Decor Brand

Launch a line of grind-textured aluminum wall panels, address numbers, signage, and furniture accents. The wheel’s fast-cutting coarse grit lets you produce distinctive textures at scale; sell via Etsy, local markets, and B2B to interior designers seeking industrial-modern finishes.

Scrap Value Optimization Service

Help recyclers and contractors increase aluminum scrap payouts by removing embedded steel fasteners and brackets. Use the Type 27 wheel to grind flush and separate mixed assemblies, improving grade and price per pound while charging a percentage of the uplift.

Creative

Shimmerwave Aluminum Wall Art

Create large wall panels from 1/8–1/4 in aluminum sheet and use the Type 27 wheel (30-grit, soft resin bond) to carve sweeping grooves, scallops, and crosshatch textures that catch light. The aluminum-oxide grain resists loading on soft metal, letting you build dramatic, reflective patterns quickly; finish with clear coat or dye to accentuate the grind marks.

Kinetic Wind Mobile

Cut scrap aluminum into fins/discs and use the wheel to round edges, add bevels, and balance pieces for a smooth spin. The depressed center profile gives good control on curves while the soft bond sheds clogging dust. Suspend elements with stainless wire for a breezy kinetic sculpture with rugged, industrial textures.

Upcycled Garden Totems

Turn old ladder rails, window-frame extrusions, and plate offcuts into stacked garden totems. Use the wheel to deburr, notch, and blend welds, then texture faces for contrast. The coarse 30-grit removes material fast on non-ferrous metals, making it easy to sculpt faceted, weather-hardy outdoor art.

Textured Coasters and Plaques

Cut aluminum blanks and grind chamfers, radial swirls, or geometric patterns for a modern set of coasters, nameplates, or small plaques. The wheel’s resin bond helps prevent loading during heavy passes; follow with finer abrasives for touch-safe edges and seal with anodize or clear coat.

Industrial Lamp Base

Fabricate a desk or floor lamp with a thick aluminum base: grind facets, smooth corners, and blend welds for a crisp, machined look. The Type 27’s reinforced construction adds stability during aggressive shaping; pair with a simple tube stem and minimalist shade for a gallery-ready piece.