Features

- One-handed trigger operation

- Reinforced nylon body with heat-treated steel bar

- Removable non-marring jaw pads

- Quick-change button converts large clamps to spreader

- Quick-release mechanism

- Safety stop

- Pump-style trigger tightening

Specifications

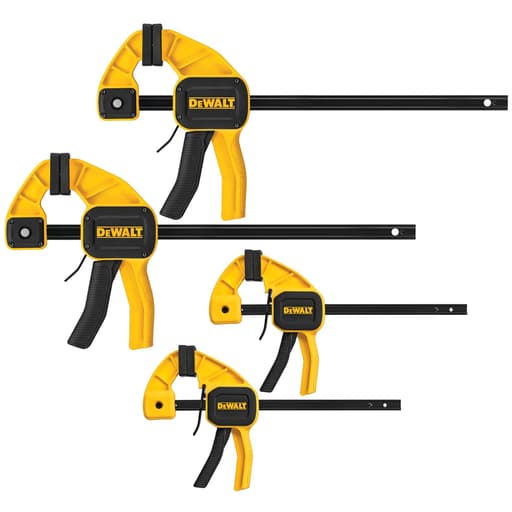

| Included | (2) 6 in. (150 mm) medium trigger clamps; (2) 12 in. (300 mm) large trigger clamps |

| Medium Throat Depth | 2-7/16 in. (62 mm) |

| Large Throat Depth | 3-1/4 in. (82 mm) |

| Medium Clamping Force | 100 lb (approx.) |

| Large Clamping Force | 300 lb (approx.) |

| Bar Material | Black oxide carbon steel I-beam |

| Body Material | Plastic (reinforced nylon) |

| Handle Material | Plastic |

| Handle Type | Trigger |

| Quick Release Mechanism | Yes |

| Safety Stop | Yes |

| Jaw Pads Material | Non-marring |

| Jaw Pad Type | Fixed / removable pads |

| Spreading Function | Yes (large clamps convert to spreader) |

| Pad Dimensions | 35 mm x 25 mm x 10 mm; 50 mm x 40 mm x 10 mm |

| Product Dimensions (Without Packaging) | 305 mm x 170 mm x 40 mm; 485 mm x 250 mm x 45 mm |

| Product Weight | 2000 g (2 kg) [pack weight] |

| Packaging | Hang tag |

| Warranty | Limited lifetime warranty |

Related Tools

Related Articles

Four one-handed trigger clamps (two medium, two large) intended for holding workpieces during assembly or while adhesives cure. The clamps have a reinforced nylon body with a heat-treated steel bar, removable jaw pads to protect surfaces, and a mechanism that allows the large clamps to convert to a spreader.

DeWalt 6 in. (150 mm) and 12 in. (300 mm) Trigger Clamps - 4 Pack Review

First impressions

Adding more clamps to the shop rarely feels glamorous, but this DeWalt trigger clamp 4-pack has turned into one of those reach-for-it-every-day sets. You get two 6-inch mediums and two 12-inch larges, which covers a surprising amount of day-to-day work—holding a straightedge for circular saw cuts, locking down pocket-hole assemblies, tacking parts while glue sets, and general bench tasks. They feel balanced in hand, the triggers are predictable, and the mix of sizes is genuinely useful.

Build and design

The bars are black-oxide carbon steel with an I-beam profile, and the bodies are reinforced nylon. That combination keeps weight down while resisting torsion better than the flat bars you’ll see on bargain clamps. The pack isn’t heavy (about 2 kg total), and the clamps don’t feel bulky in a tool bag or hanging off the bench.

- Throat depth: 2-7/16 in. (medium), 3-1/4 in. (large)

- Claimed force: roughly 100 lb (medium), 300 lb (large)

- Pads: removable, non-marring; medium approx. 35 x 25 x 10 mm, large approx. 50 x 40 x 10 mm

- Quick release: yes; pump-style trigger with a safety stop

- Spreader function: on the large clamps only (tool-free, quick-change button)

The jaw casting is tidy, the bar is straight, and there’s a sensible safety stop at the tail so the head doesn’t shoot off the end when you pull it back.

In use: clamping performance

For their size class, the larges have ample bite. I used them to pull together 3/4-inch poplar carcass joints and to lock a 1x straightedge to plywood for long circular-saw rips. They held without creeping, and the jaws remained parallel enough that I didn’t need to shim for most work. The mediums are perfect for pocket-hole face-frames, small glue blocks, and general holding on the bench where finesse beats brute force.

The pump trigger is predictable: each squeeze advances in small increments and you can “sneak up” on final pressure without jumping past it. Under load, release is smooth if you keep a finger on the work; if you’re maxed out, expect to give the release lever a solid squeeze.

Would I trust the large clamp as my only pressure source for a heavy tabletop glue-up? No. For that, F-style or pipe clamps still rule. But for alignment and moderate pressure while the main clamps do the heavy lifting, they’re excellent.

One-handed operation: the reality

These are marketed as one-handed, and most of the time they are—if the jaws are already near the work. Where they lag behind some premium quick-grips is in sliding the head rapidly along the bar with gravity alone. The heads don’t “freefall” as readily as older, heavier-headed designs, so moving from fully open to contact often takes a second hand. A few notes:

- If the bar is clean and dry, I can push the head with the thumb while holding the clamp one-handed.

- Dust or pitch on the bar increases friction noticeably. A wipe with a rag and a shot of dry lube or paste wax makes a big difference.

- Once the jaws touch the work, the pump action is legitimately one-handed and controlled.

If you routinely need to reposition the head across the bar with one hand and no support, there are smoother options. For most shop tasks, this is a minor inconvenience rather than a deal-breaker.

Spreader mode (large clamps)

Converting the large clamps to spreaders is quick: press the button, pop the fixed jaw to the other end, and you’re in business. I used them to gently push face frames into alignment and to set the distance between cabinet sides while installing cleats. The action is as controlled in spread mode as in clamp mode, which is important when you’re applying outward pressure around finished edges. Note that the mediums do not convert.

Pads and surface protection

The removable pads are grippy and don’t mar prefinished plywood or paint. They sit flat, though the outer corners can ride up on tight edges. I like that they’re removable for cleaning or replacement.

A couple of caveats from my bench time:

- Avoid solvents and heat. The pad material can harden if you clean with aggressive chemicals.

- If you clamp on very sharp arrises, consider a backing block or slip on a leather/tape guard to prolong pad life.

I’ve not had the pads crumble, but I did see one medium pad develop a small chip after a clamp toppled onto the concrete. Replacements or DIY pads (leather, cork, UHMW tape) are simple fixes.

Ergonomics and control

The handles are shaped well for medium hands, and the trigger angle lets you apply full pressure without wrist contortions. Under near-maximum load, the release lever does require a committed squeeze. If you have smaller hands or reduced grip strength, you may prefer a clamp with a bigger lever ratio for releasing heavy loads.

Balance is good in both sizes. They hang off the bench without tipping, and the bar doesn’t flex excessively when fully extended. I measured minimal jaw deflection on the larges when cranked hard over 8–10 inches of opening—well within what I expect for this class.

Capacity and reach

The 6-inchers will cover most jig work and small assemblies; the throat depth of 2-7/16 in. reaches comfortably past edge banding and face frames. The 12-inchers will span typical cabinet sides and longer guide-rail setups, and the 3-1/4 in. throat depth gives you more clearance around irregular profiles. If you need to bridge deeper carcasses or long glue-ups, step up to longer bars or a different clamp style.

Durability and maintenance

The reinforced nylon bodies have shrugged off ordinary knocks, and the oxide-coated bars resist surface rust well. I’d avoid using these as wedges or prybars—trigger clamps don’t like torque abuse. Keep the bars clean; fine dust builds up and makes the slide sticky. A quarterly wipe-down and a dry lubricant keep them working one-handed as designed.

On warranty, DeWalt lists a limited lifetime policy. As always, expect it to cover defects, not misuse. Replacement pads and screws are worth keeping in a drawer for the inevitable shop mishaps.

Where they shine

- Quick alignment for casework and face frames

- Holding straightedges and track saw guides

- Pocket-hole assemblies and jig work

- Temporary fixtures on a portable bench or folding table

- Light-to-moderate glue-ups where even pressure and control matter

Where they fall short

- Not the right tool for high-pressure glue-ups or construction tasks where parts fight you. Use F-style, parallel-jaw, or pipe clamps.

- The head doesn’t glide along the bar as freely as some premium quick-grips, so occasional two-handed positioning is needed.

- Release effort under maximum load is higher than average.

Value

As a four-pack with two useful sizes, the value proposition is solid. You’d spend as much on two premium quick-grips as you would on this entire set, and for general shop work these deliver most of what you need. The spreader function on the large pair adds versatility you’ll actually use.

Tips for best results

- Keep the bar clean and apply dry lube or paste wax to improve one-handed sliding.

- Use backing blocks on sharp edges to protect pads and distribute pressure.

- Don’t over-crank trying to make these do a pipe clamp’s job. Use the right clamp for the load.

- Store with jaws closed lightly to keep pads from taking a set.

Recommendation

I recommend this DeWalt trigger clamp set for woodworkers and DIYers who need a reliable, everyday set of quick-grips for assembly, alignment, and workholding around the shop. The large clamps supply ample force for their size, the mediums are handy for jigs and light clamping, and the spreader mode is genuinely useful. They aren’t the smoothest sliding clamps I own and they’re not substitutes for heavy-duty glue-up clamps, but as a versatile, good-value four-pack, they’ve earned a permanent hook on my wall.

Project Ideas

Business

Mobile Glue-Up Service

Offer on-site glue-up and clamping for DIYers and small contractors who lack enough clamps. Provide cauls, alignment blocks, and these trigger clamps to assemble tabletops, frames, and trim. Charge per visit plus hourly, with a premium for rush curing and pickup/delivery.

Bent-Wood Home Goods Microbrand

Produce small-batch bent-laminate goods—key racks, headphone stands, wall hooks—using forms and the 12 in. clamps for consistent curves. Sell on Etsy and at markets. Emphasize clean surfaces thanks to non-marring pads and fast turnaround enabled by quick-release changes.

On-Site Cabinet/Fit-Out Assistance

Specialize in cabinet installs: use clamp pairs to hold face frames flush for fastening, align fillers, and in spreader mode to gently press gables against walls during scribing. Bill as a per-day subcontractor service to busy installers who need an extra set of hands.

Clamping and Assembly Workshops

Run weekend classes teaching glue-up strategy, pressure distribution, and jig-making. Each attendee builds a small project (e.g., cutting board or frame) using the clamps. Monetize via tuition, upsell starter clamp sets, and sponsorships from local lumberyards.

Weekend Clamp Rental

Create a rental ‘Clamp Kit’ with these trigger clamps, cauls, and corner squares. Offer 48–72 hour rentals with deposits and optional delivery. Target DIY renovators needing temporary clamping capacity for flooring transitions, trim, or panel glue-ups.

Creative

Bent-Laminate Coat Hooks

Steam or soak thin hardwood strips and laminate them over a simple plywood form. Use the 12 in. clamps to apply even pressure along the curve while the glue cures; the non-marring pads protect the wood. Once set, cut to length, sand, and finish. Mount several on a board for a minimalist wall rack.

Patterned Cutting Boards

Rip contrasting hardwood strips, arrange into patterns (checkerboard, herringbone), and glue up. Use both 6 in. and 12 in. clamps with cauls to keep the panel flat. The one-handed triggers simplify alignment while the quick release speeds up repositioning between glue-ups.

Custom Picture Frame Jig

Build a simple 90° corner caul set and use the medium clamps to pull miters tight without bruising the wood. Convert the large clamps to spreaders to gently push opposing sides outward for perfect joint alignment before pinning or splining.

Resin River Coasters

Create a silicone-lined mold; clamp two small live-edge pieces against straight cauls to define the ‘river’ gap. The non-marring pads prevent dents, and the pump-style trigger dials in pressure so resin doesn’t squeeze out excessively. After cure, slice into coasters and finish.

Canvas or Acoustic Panel Stretchers

Build a rectangular frame, staple fabric on one side, then use the large clamps in spreader mode inside the frame to tension opposite sides progressively. This yields a smooth, taut surface for canvas art or fabric-wrapped acoustic panels.