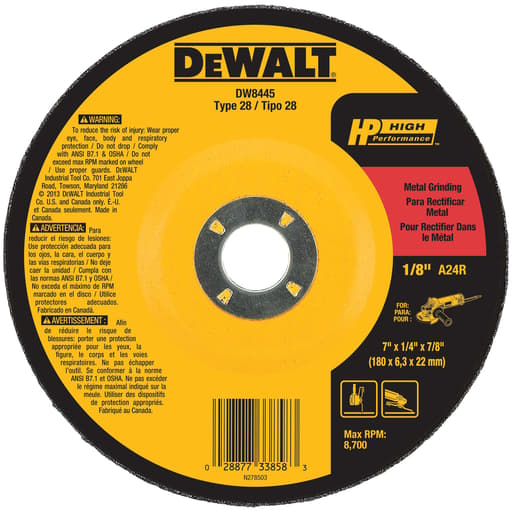

Features

- Aluminum oxide abrasive for material removal and extended life

- Type 28 depressed‑center shape for increased surface grinding coverage

- Three full-sheet fiberglass reinforcement for durability and safety

Specifications

| Wheel Diameter | 7" |

| Wheel Thickness | 1/4" |

| Arbor | 7/8" |

| Wheel Type | Type 28 |

| Grade | A24R |

| Maximum Rpm | 8,700 |

| Intended Use | Steel, stainless steel |

| Pack Quantity | 10 |

| Sku | DW8445 |

Related Tools

Related Articles

Type 28 aluminum-oxide abrasive wheel intended for grinding metal. The wheel is reinforced with three full sheets of fiberglass for strength and safety. Designed for use on steel and stainless steel and rated for a maximum operating speed of 8,700 RPM.

DeWalt Metal grinding wheel (Type 28) Review

What it is and where it shines

I’ve been running the DeWalt Type 28 wheel on a 7-inch grinder for a few weeks across a mix of shop tasks: weld removal on mild steel, beveling thick plate for full-penetration welds, and knocking down stainless fabrications before finishing. In short, this is a straightforward, aggressive stock-removal wheel that favors durability and control over finesse. If you’re used to thin cut-off discs or lighter-duty grinding wheels, the first thing you’ll notice is the mass and the confidence it brings. It’s not a precision cutter—nor is it meant to be—but it will move metal efficiently and keep its shape as you go.

Shape, build, and specs that matter

Type 28 refers to the “saucer” profile with a depressed center. Compared to the more common Type 27, this shape gives a slightly angled face that’s great for weld blending, edge work, and getting into corners without riding on the guard. It encourages a steeper working angle (I find 15–30 degrees works well), which helps the wheel bite and keeps the contact patch manageable.

Key specs:

- 7-inch diameter, 1/4-inch thick, 7/8-inch arbor

- A24R spec: coarse 24 grit aluminum oxide with a relatively hard bond

- Rated to 8,700 RPM

- Intended for steel and stainless

- Three full fiberglass reinforcement sheets

- Sold in a 10-pack

That A24R spec tells you a lot about how it behaves. The 24 grit is coarse and fast, while the harder “R” bond prioritizes wheel life and shape retention. The three-sheet reinforcement is a reassuring detail for a wheel that will see side loads during grinding.

Setup and balance

On a standard 7-inch grinder with a 7/8-inch arbor, the wheel seats cleanly and runs true. I didn’t notice any imbalance, and it spins up smoothly—though like any 7-inch consumable, you’ll feel the inertia. I used it on a 13-amp grinder and a lower-tier unit; both handled it fine, but the higher-powered machine maintains speed better under heavy pressure. Keep the guard on and oriented properly; the depressed center gives you some clearance, but you still want the guard doing its job when you hit a corner or change angles.

Performance on steel and stainless

- Weld removal: On 1/4-inch fillet welds, a quick pass at a moderate angle removes the crown efficiently without jumping. I could feather into base material without digging divots. The wheel keeps a flat face rather than dishing out quickly, which helps maintain even bevels.

- Beveling: For prepping 3/8-inch and 1/2-inch plate, the wheel makes consistent bevels with predictable wear. As the edge rounds off through use, you can roll the grinder slightly to keep a consistent land.

- Mill scale and heavy rust: It eats scale quickly, though it’s overkill if you only need a clean surface for painting. I’d still pick it for heavier scale or when you also need to kiss down weld spatter.

- Stainless work: It’s rated for stainless, and I used a dedicated wheel on 304 angle to avoid cross-contamination. It didn’t load up or smear, and it held a steady bite. You’ll still want to follow with a flap disc if you’re chasing a refined finish to avoid excess heat tint.

The surface it leaves is rough—as expected from 24 grit—so any cosmetic work needs a follow-up with a flap disc. But for raw stock removal, it’s efficient, predictable, and controllable.

Cutting vs. grinding

This is a grinding wheel first. You can make rough cuts in a pinch by using the edge, but it’s not fast or precise, and it generates more heat than a thin cut-off wheel. If your goal is straight, clean cuts in tube or sheet, grab a .045-inch cut-off disc instead. Where this wheel shines is shaping, blending, and removing bulk material safely and with less risk of shattering than a thin disc.

Heat, control, and technique

- Working angle: 15–30 degrees is the sweet spot. Too shallow and it skates; too steep and you’ll gouge and generate excess heat.

- Pressure: Moderate pressure keeps the wheel self-sharpening. Leaning too hard can glaze the bond and slow it down.

- Heat management: Keep the wheel moving to avoid bluing, especially on stainless. If you see straw or blue colors quickly, back off pressure and let the abrasives do the work.

- Spark stream: Expect a heavy spark stream on mild steel; the bite is reassuring and helps you “read” the wheel’s engagement.

The Type 28 profile makes it easier to blend weld toes without nicking adjacent surfaces, and it’s helpful in corners where a flat wheel struggles to make contact.

Durability and wear pattern

The 1/4-inch thickness and hard bond extend the usable life. I got several hours of productive grinding per wheel on structural steel tasks—longer than many mid-priced alternatives. The three-sheet fiberglass reinforcement provides a noticeable sense of stability. The wheel wears evenly, holds its face, and doesn’t fracture under normal side loads. As always, inspect regularly; swap out a wheel if you see cracking, chunking, or embedded debris.

Safety and compatibility

- Verify your grinder’s no-load speed is at or below 8,700 RPM. Most 7-inch grinders are in the 8,000–8,500 range, which is appropriate.

- Keep the guard on, wear eye and face protection, gloves, and hearing protection.

- Ring-test new wheels before mounting, and avoid dropping them.

- Use dedicated wheels for stainless if you’re concerned about cross-contamination—don’t mix them between carbon steel and stainless projects.

- Store the 10-pack in a dry place, flat, and away from solvents or extreme temperatures.

Value

Buying in a 10-pack makes sense if you do frequent fabrication: per-wheel cost is reasonable, and the life is above average for an aluminum-oxide wheel in this class. If you’re a casual user who only occasionally grinds, a single or twin pack might be more sensible—though having spares on hand is never a bad idea. For daily weld cleanup and prep, the consistency and durability reduce swap-outs and interruptions.

Limitations and alternatives

- Finish quality: 24 grit leaves a rough surface. Plan on a flap disc (40–60 grit) or a fiber disc for blending.

- Precision cuts: It’ll muddle through, but thin cut-off discs are the right tool for cutting stock to length.

- Exotic alloys or maximum removal rate: For the fastest stock removal or cooler grinding on stainless and high alloys, ceramic or zirconia flap discs and fiber discs can outperform aluminum oxide—at a higher consumable cost.

- Aluminum: Not the best pairing. Aluminum tends to load aluminum-oxide wheels. Use a dedicated non-loading disc or apply a wax stick designed for non-ferrous metals.

Who it’s for

- Fabricators and welders who need reliable weld removal and beveling on steel and stainless

- Maintenance crews tackling heavy rust and scale, bolt heads, and brackets

- DIYers upgrading from thin, brittle wheels who want something safer and longer-lasting for rough shaping

If your day is mostly light deburring, a smaller wheel or a flap disc might be more comfortable. If you’re doing precision cutting, stick with cut-off wheels.

Recommendation

I recommend the DeWalt Type 28 wheel for anyone running a 7-inch grinder who needs dependable, aggressive stock removal on steel and stainless. It combines a useful Type 28 profile with a durable 1/4-inch build and a hard-bond A24R spec that holds up under real-world pressure. It’s not the fastest path to a fine finish and it’s not a precision cutting tool—but that’s not what it promises. For weld cleanup, beveling, and general shaping, it’s stable, long-lasting, and predictable, which is exactly what I want from a grinding wheel. If you pair it with a flap disc for final blending and keep a cut-off wheel nearby for precise cuts, this becomes a workhorse consumable that earns its keep in the shop.

Project Ideas

Business

Mobile Weld Seam Blending Service

Offer on-site weld blending and edge finishing for fabricators, gate and railing installers, and artists. Use the Type 28 wheel for fast surface coverage, blending MIG or TIG seams on steel and stainless. Charge per job or per linear foot.

Rust and Mill-Scale Removal Prep

Provide surface preparation for repainting or powder coating by grinding off mill scale, rust, and weld spatter on structural steel and fabrications. Price by square foot with add-ons for priming and cleanup.

Sharp Edge Mitigation for Facilities

Serve factories and construction sites by chamfering and deburring cut plates, stair treads, handrail ends, and mezzanine components. Reduce injury risk and improve compliance; set up scheduled maintenance visits.

Custom Ground-Finish Signage and Panels

Produce logos and decorative panels from stainless or cold-rolled steel using masked grind patterns for depth and sheen. Clear-coat and sell to cafes, breweries, and architects; offer installation and mounting hardware.

Hands-On Grinder and Finishing Workshops

Run small classes teaching safe grinder operation, wheel selection, weld blending, and surface finishing on steel and stainless. Monetize through ticket sales and upsell consumables like wheel packs.

Creative

Ground-Texture Metal Wall Art

Create wall panels from scrap steel or stainless sheet and use the Type 28 wheel to lay broad swirl, wave, or feather grind patterns. Mask sections with stencils for negative-space designs, then clear-coat or oil-finish for contrast.

Forged Bottle Openers With Blended Finishes

Forge simple steel openers, then use the wheel to remove scale, blend transitions, and add decorative scallops or directional grain. Leave some hammer marks and polish select areas for a rugged, gift-worthy look.

Industrial Steel Coffee Table Frame

Fabricate a steel frame and use the wheel to flush and blend welds, break sharp edges, and create a uniform brushed grind pattern. Pair with a wood, stone, or glass top for an industrial aesthetic.

Garden Sculpture With Faceted Highlights

Weld rod and plate into abstract forms and use the depressed-center wheel to sculpt facets and reflective planes. Seal with clear coat for stainless or a controlled patina for steel to enhance textures.

Custom BBQ Tools From Stainless Flat Bar

Cut spatulas or pokers from stainless flat bar and use the wheel to shape bevels, round edges, and add decorative grind lines. Finish with heat-resistant handles and a brushed grind aesthetic.