Features

- Carbide grit edge for improved wear resistance

- Steel wheel body to help maintain cutting speed and depth

- Laser-bonded carbide grit to the steel body for stronger adhesion

- Thin wheel profile for cutting in confined or hard-to-reach areas

- Compatible with standard 3" mini grinders using a 3/8" arbor

Specifications

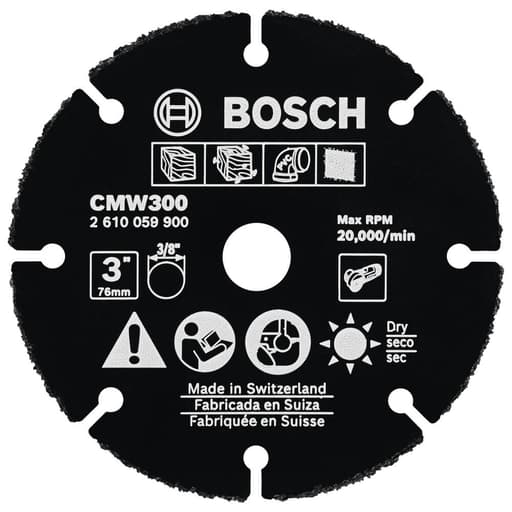

| Model Number | CMW300 |

| Order Number | 2610059900 |

| Material | Carbide grit on steel body |

| Diameter (In) | 3 |

| Bore Diameter (In) | 0.375 |

| Thickness (In) | 0.28 |

| Pack Quantity | 1 |

Related Tools

Related Articles

3-inch carbide cutting wheel designed for use with mini angle grinders. Carbide grit is bonded to a steel body to provide extended cutting life and consistent cutting performance. Intended for cutting a range of materials and for use on 3-inch mini grinders with a 3/8-inch arbor.

Bosch Carbide Multi-Wheel for Mini Angle Grinders Review

Why I reached for this wheel

Mini angle grinders are brilliant for quick, tight-quarters work—snipping a stubborn screw, trimming a bit of flashing, or scoring a cut where a full-size grinder won’t fit. The Bosch carbide mini wheel (model CMW300) is built exactly for that role: a 3-inch, carbide-grit edge bonded to a steel body, meant to tackle a mix of materials without swapping discs every five minutes. I spent time using it for small repairs and shop tasks to see where it excels and where it doesn’t.

Setup, fit, and compatibility

The wheel’s 3/8-inch bore dropped cleanly onto my 3-inch mini grinder’s arbor without fuss, and it seated flat between the flanges. Balance was good—no noticeable wobble, and spin-up was smooth. If you’re used to thin resin-bonded cutoff wheels, this steel-bodied design feels more rigid and confidence-inspiring. The thin profile helps in tight spaces under sink cabinets and inside electrical enclosures, where clearance is everything.

One practical note: with a 3-inch wheel, your max cutting depth is inherently limited. Expect something in the three-quarter-inch neighborhood depending on your guard and approach angle. That’s fine for screws, small angle bracket trims, sheet stock, and pipe up to about 1/2 inch, but it’s not your tool for thick bar stock.

As always, check your grinder’s RPM against the wheel’s rating and run a guard. The wheel throws typical grinder debris—sparks with metal, dust with wood and plastics—so PPE is not optional.

Cutting performance across materials

Mild steel: On 18–20 gauge sheet and standard screws/bolts, the carbide grit bites in steadily without the “grab” you can get from toothed accessories. It’s not as fast as a fresh abrasive cutoff wheel in a straight line, but it’s more controllable and less prone to shattering. I trimmed a galvanized angle bracket and lopped off three protruding screws flush with a cabinet face. Cuts were predictable, and heat stayed manageable as long as I kept the feed light and let the grit do the work.

Stainless hardware: For small-diameter stainless screws, it works, albeit slower. The grit doesn’t glaze over quickly, and I didn’t see chunking or grit loss. I wouldn’t choose it for repeated stainless rod cuts, but for occasional hardware cleanup, it’s practical.

Aluminum and copper: The wheel handled 1/2-inch copper pipe and a strip of aluminum trim cleanly. Light feed avoids loading; if you push too hard on soft metals, you’ll smear and heat things up. I saw minimal loading and cleared the edge by easing off and letting RPM do the cleaning.

Plastics and PVC: Good control, with a consistent kerf and less melting than I expected. The rasp-like edge of the carbide grit actually helps here; keep the grinder moving to avoid local heat buildup and you’ll get a clean cut on Schedule 40 PVC.

Wood (including nails): This is where the design makes sense. Unlike toothed wood blades—which I avoid on grinders because of kickback risk—the grit edge tracks with less tendency to self-feed. I made plunge openings in plywood and cut a notch in a 2x for a repair, intentionally crossing embedded brads. Progress is steady rather than aggressive, and the cut face is rougher than a saw’s, but the control is excellent for a grinder. Use a light touch and keep your stance braced; it’s still a grinder.

Cement board and soft masonry: It will score fiber cement and backerboard in a pinch, but this isn’t a diamond blade. Expect a slower rate and more dust. For porcelain or stone tile, use the proper diamond wheel.

Overall cutting speed is in the “deliberate but safe” category. If raw speed is your only metric, a fresh, material-specific disc will beat it. If you value one wheel that can handle mixed materials without swapping, the Bosch wheel hits a sweet spot.

Cut quality and control

Because the edge is grit and not teeth, the wheel tracks straighter on thin metals and plastics with less grabbing. I could follow a scribed line on sheet metal without a fight, and a light oscillating motion helped keep the kerf clean. On wood, the edge leaves a coarse finish—think rasp, not saw. Plan to sand or plane to a line if appearance matters.

Heat management is good for the size. The steel body acts like a small heat sink, so you don’t get that “rubber band” feeling as the wheel wears. The cut depth stays consistent longer than on comparable abrasive discs that shrink quickly.

Vibration was minimal on my setup, which matters for accuracy and user fatigue. Noise is typical grinder territory—not louder than usual, but I did notice a slightly lower-pitched “hiss” from the grit edge on wood and plastics versus the shriek of a resin disc on steel.

Durability and grit retention

Bosch laser-bonds the carbide grit to the steel body, and I saw the benefit there. After a week of mixed-material cuts—sheet steel, copper pipe, PVC, and half a dozen wood notches—the wheel still had an aggressive edge with no bald patches. The wear pattern was even, and there was none of the chunking I’ve seen on cheaper grit wheels where a section simply lets go. I did a quick pass on scrap steel periodically to refresh the edge and it seemed to deglaze effectively.

Compared to a stack of resin cutoff wheels, this single wheel lasted longer in mixed use and didn’t require babysitting to avoid cracking. You’re trading upfront cost for longevity and convenience, and in my use, that math worked out.

Safety considerations

- Use the guard and keep both hands on the grinder. The wheel is forgiving, but it’s still a grinder accessory.

- On wood, resist the urge to force a plunge. Let the grit ease its way in; it reduces kickback risk and leaves a straighter entry.

- Don’t side-grind with the rim. The body is steel, but the grit edge is designed for cutting, not heavy lateral grinding.

- Manage debris: sparks on metal and fine dust on wood/plastic—respirator, eye and ear protection are a must.

Limitations to keep in mind

- Depth of cut is limited by the 3-inch diameter; not the right choice for deep material.

- It’s a generalist. Specialized discs (thin kerf metal cutoffs, diamond tile blades, wood-specific saws) are faster and cleaner in their niches.

- Not ideal for thick or hardened steel. It can handle small hardware and thin sections, but you’ll be there a while on anything substantial.

Who benefits most

- Maintenance techs, remodelers, and punch-list pros who encounter mixed materials in tight spaces.

- DIYers who want one wheel living on a mini grinder for quick “grab and go” fixes around the house or shop.

- Electricians and plumbers making small openings, trimming fasteners, and cutting pipe where a hacksaw or oscillating tool is awkward.

If your work is primarily heavy metal fab or precision woodworking, this won’t replace your core blades and discs. It’s an adjunct for odd jobs and tight locations.

The bottom line

The Bosch carbide mini wheel does exactly what a good multi-material accessory should: it trades single-material speed for broad usefulness, control, and durability. Fit and balance were solid, the carbide edge stayed intact through real-world abuse, and I spent more time cutting and less time swapping discs. Its small diameter is a built-in limitation, but that’s also what makes it so handy in confined spaces.

Recommendation: I recommend this wheel for anyone running a 3-inch mini grinder who wants a dependable, single accessory for light-to-medium cuts across metal, plastics, and wood (including the occasional nail). It’s not the fastest tool for any one material, and it won’t replace dedicated blades for deep or heavy cuts, but it earns its keep through longevity, control, and versatility. If your day includes varied, small tasks in tight spots, this belongs in your kit.

Project Ideas

Business

On-Site Fastener Removal & Flush-Cut Service

Offer a mobile service to cut seized bolts, trim protruding nails/screws, and slice rusted hardware in tight spaces where larger tools won’t fit. Bill per callout plus time, serving property managers, auto/marine shops, and contractors.

Tile/Stone Notching & Modification

Partner with tile installers to handle tricky L-cuts, outlet openings, and on-the-fly adjustments in porcelain, ceramic, and stone. The thin carbide wheel excels at precise notches on-site, reducing install delays.

Custom Small-Part Fabrication Micro-Shop

Produce small runs of brackets, switch plates, trim rings, vent covers, and grommet plates from sheet aluminum/steel and PVC. Market to makers and renovators needing quick turnaround for bespoke dimensions.

Upcycled Metal Decor Product Line

Launch an online shop selling wall hooks, key racks, bookends, and minimalist sculptures made from cut scrap metal. The wheel’s long life lowers consumable costs, and the compact setup suits small-batch production.

HVAC/Plumbing Cut-to-Fit Support

Provide on-call trimming for ductwork, EMT conduit, registers, and PVC/ABS during installs and retrofits. The 3-inch wheel’s maneuverability helps with confined chases and tight mechanical rooms, keeping crews moving.

Creative

Layered Metal Cityscape Wall Art

Cut skyline silhouettes from thin steel or aluminum sheet, then stack and offset multiple layers for depth. The thin 3-inch carbide wheel lets you nibble tight details and clean edges in confined areas, and the wear-resistant grit handles repeated cuts through mixed scrap.

Mosaic Tile Planters & Stepping Stones

Create custom-shaped tile shards and stone accents for planters and garden pavers. The carbide grit edge is great for scoring and cutting ceramic, porcelain, and cementitious materials, enabling precise inlays and curved motifs.

Industrial Coat Rack From Upcycled Tools

Repurpose old wrenches, bolts, and rebar into a wall-mounted coat rack. Use the wheel to cut lengths, trim hardware, and flush-cut protruding screws for a clean, intentional look with rugged character.

Mixed-Material Table Lamp

Design a lamp using copper pipe, perforated steel, and hardwood. The mini grinder’s small wheel makes tight, controlled cuts in copper and thin sheet, helping you fabricate custom shades, brackets, and wire channels.

Custom Garden Trellis & Markers

Cut thin steel or aluminum into geometric trellis panels and herb markers. The steel-bodied, laser-bonded wheel maintains cutting speed and depth, so you can repeat shapes consistently for a cohesive garden set.