Features

- High-concentration aluminum oxide abrasive for efficient cutting and longer life

- Two layers of fiberglass reinforcement for strength and safety

- Formulated free of iron, sulfur, and chlorine to minimize contamination during stainless steel cutting

- Designed for use on stationary and chop saws (Type 1)

Specifications

| Diameter | 12 in |

| Thickness | 7/64 in |

| Arbor Size | 1 in |

| Pack Quantity | 10 |

| Abrasive | Aluminum oxide |

| Reinforcement | Two layers of fiberglass |

| Compatible Materials | Stainless steel |

| Contaminant Exclusions | No added iron, sulfur, or chlorine |

Related Tools

Related Articles

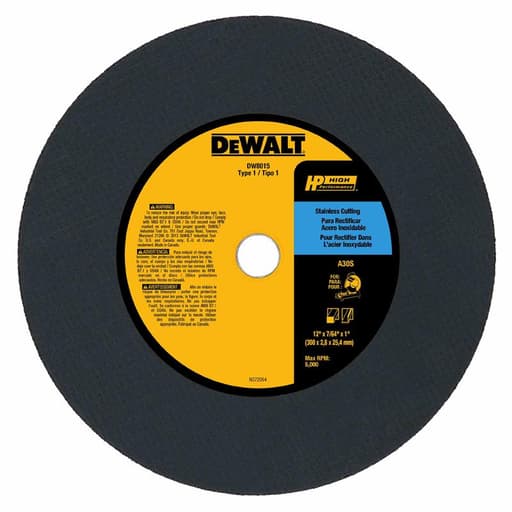

Type 1 cutting wheel intended for use on stationary and chop saws to cut stainless steel. The wheel uses a concentrated aluminum oxide abrasive to increase material removal and extend wheel life. It is reinforced with two layers of fiberglass and is manufactured without added iron, sulfur, or chlorine to reduce contamination when cutting stainless steel.

DeWalt Stainless Steel Cutting Type 1 Stationary and Chop Saw Wheel Review

Why this stainless cut-off wheel earned a spot in my shop

A good stainless cut-off wheel earns its keep the first time you face a bundle of 304 and need clean, repeatable cuts without contaminating your weld areas. I’ve been running the DeWalt stainless chop-saw wheel on a stationary cutoff saw with a 1-inch arbor, and it’s become a predictable, low-drama option for day-to-day stainless work. It strikes a sensible balance between cut speed, wheel life, and heat management—exactly the mix I want when I’m bouncing between thin-wall tube and thicker flat stock.

Build, specs, and what stands out

- Diameter: 12 inches

- Thickness: 7/64 inch (a nice middle ground between 3/32 and 1/8)

- Arbor: 1 inch

- Abrasive: Aluminum oxide, high concentration

- Reinforcement: Two layers of fiberglass

- Purpose: Stainless steel, with no added iron, sulfur, or chlorine

- Format: Type 1 (flat), for stationary and chop saws

- Pack: 10 wheels

The 7/64-inch thickness is a smart choice. It holds a line better than thinner wheels, yet still cuts faster and with less heat than a full 1/8-inch disc. The dual fiberglass reinforcement inspires confidence under load—no flexy, drifty feel—and the iron/sulfur/chlorine-free formulation is what I want for stainless so I’m not smearing contaminants into the cut face before welding.

Setup and compatibility

The wheel fits the standard 1-inch arbor used on many stationary cutoff saws. If your saw takes a different size, plan on a proper, flat-fitting bushing—don’t hack it with tape or a wobbly adapter. Because it’s a 12-inch wheel, check your saw’s guard and maximum capacity; if your saw is set up for 14-inch wheels, you’ll lose some cut depth with a 12-inch wheel. No issues with my 12-inch machine.

As always with Type 1 wheels, use flat flanges in good shape, keep the blotter between the wheel and flanges, torque to spec (snug, not gorilla), and run the guard. Give the wheel a quick ring test before mounting and let it spin up to speed for a few seconds before the first cut.

Cutting performance

I ran this wheel through a handful of common stainless profiles:

- 304L 1-1/2 x 0.065-inch tube: quick, clean cuts with a light, consistent feed

- 304 2-inch x 1/4-inch flat bar: steady progress without bogging

- 316L 1-1/2 x 1/8-inch angle: predictable, low chatter

Feed pressure is the real differentiator with this wheel. It likes a firm but patient hand. Push too hard and you’ll glaze the abrasive and add heat; let the wheel do the work and it tracks straight with minimal burr formation. On thin-wall tube, my cut times landed in the 6–10 second range; on 1/4-inch flat bar, closer to 15–20 seconds. The wheel never felt grabby, and I didn’t see the edge wandering off the line unless I got careless with clamping or rushed the feed.

Cut quality is good for an abrasive chop: square ends with manageable burrs and a heat-affected stripe that didn’t extend far past the cut line. The finish is consistent enough that a quick pass with a flap wheel or a deburring tool cleans it up for welding.

Heat, discoloration, and contamination control

You can’t avoid some heat tint with abrasive chops, but this wheel keeps it in check as long as you’re not forcing the cut. The stainless-friendly formulation matters here. After cutting, I wiped the edges with a cleaner and left a few test pieces on the bench—no suspicious rust blooms or brown haze the next day. If you’re TIG-welding stainless and want to minimize post-cut prep, using a wheel with no added iron, sulfur, or chlorine is simply the right call.

One note: if you switch this wheel between carbon steel and stainless, you’re going to cross-contaminate your stainless anyway. Dedicate a set to stainless work and mark the flanges to match.

Wheel life and value

Aluminum oxide isn’t the flashiest abrasive in 2025—ceramics and zirconia get the headlines—but DeWalt’s high-concentration mix here gives solid life. I could handle small batches (30–40 cuts in mixed 1/8- to 1/4-inch material) on a single wheel and still have useful diameter left. On thin-wall tube, the wear rate was especially slow, which is often where budget wheels melt away.

For all-day production on heavier stainless, a premium ceramic wheel will likely outlast this by a meaningful margin. But for general fab, maintenance, and job-shop work, the cost-to-life ratio lands in a sweet spot. The 10-pack format suits shops that don’t want to reorder constantly, and it keeps per-wheel cost in check.

Safety and user experience

- Stability: The dual fiberglass reinforcement keeps the wheel rigid without feeling brittle. No flutter, no wobble.

- Comfort: Fewer stalls and less feed force needed means the saw stays composed, and so do your hands.

- Spark pattern: Typical for a stainless cut—directable and not excessively bright when feed is consistent.

Remember: this is a Type 1 wheel—don’t side-load it, and don’t try to use it like a grinding wheel. Let it stop fully before setting the saw down.

Packaging and storage

My 10-pack arrived with cardboard protection and shrink wrap. The discs were well protected, but I’d love to see individual sleeves for shop storage. Once a pack is open, loose wheels are more prone to nicking and moisture exposure if they live in a drawer. If you don’t have sleeves, a simple fix is to cut dividers from chipboard and keep the set in a sealed bin with a desiccant pack.

Where this wheel fits—and where it doesn’t

Choose this wheel if:

- You’re cutting stainless on a stationary or chop saw and want to avoid contamination without jumping to premium-price ceramic abrasives.

- You want a balanced thickness that tracks straight yet cuts faster than 1/8-inch discs.

- You value predictable performance across varied stainless stock—tube, bar, angle—without babying the cut.

Consider alternatives if:

- You need burr-free, cool cuts with minimal cleanup—then a carbide dry-cut saw or cold saw is the tool for the job.

- You’re pushing heavy stainless all day—premium ceramic wheels may provide better life, offsetting the higher price.

- Your saw is set up around 14-inch capacity—running a 12-inch wheel will limit cut depth.

Tips for best results

- Clamp aggressively. Stainless loves to sing; solid fixturing keeps the cut straight and your feed steady.

- Use a consistent, moderate feed. If you hear the wheel start to glaze, ease up and let it self-sharpen.

- Keep the line. Start with a shallow score cut to establish the kerf before committing full pressure.

- Mind the flanges and blotters. Clean, flat contact surfaces prevent chatter and premature wear.

- Dedicate wheels to stainless. Don’t bounce between carbon and stainless with the same disc.

The good and the not-so-good

Pros:

- Clean stainless cuts with reduced risk of contamination

- Balanced 7/64-inch thickness: stable, relatively fast, manageable burrs

- Strong reinforcement; confident, chatter-free tracking

- Sensible life for the price, especially on thin-wall tube

- Pack of 10 is convenient for shop inventory

Cons:

- 12-inch diameter limits capacity on saws set up for 14-inch wheels

- Aluminum oxide won’t match ceramic wheels for life in heavy-duty, all-day use

- No individual sleeves in the pack makes shop storage less tidy

Recommendation

I recommend the DeWalt stainless chop-saw wheel for fabricators, maintenance crews, and job shops that routinely cut stainless on a stationary or chop saw and want reliable performance without the premium price of ceramic abrasives. It delivers clean, consistent cuts, respects stainless by avoiding Fe/S/Cl contamination, and offers a smart balance between speed and longevity. If your workflow is heavy section, high-volume cutting, there are more durable (and more expensive) options. For everything else, this wheel hits the mark and earns a spot on the shelf.

Project Ideas

Business

Stainless Cut-to-Length Service

Offer precise, quick-turn cutting of stainless tube, rod, and angle for local welders, makers, and contractors. Market the contamination-free cuts (no added Fe/S/Cl) for clients who TIG weld or need food-grade/marine-grade parts. Sell by the piece with tiered pricing and minimums.

DIY Railing and Furniture Kits

Produce flat-pack stainless kits: cable railing posts, table/bench bases, and shelf bracket sets. All parts pre-cut on the stationary saw for repeatability; include hardware and instructions. Sell online with options for custom lengths and finishes.

Restaurant/Brewery Stainless Fabrication

Niche service making and modifying stainless worktables, splash guards, shelving, and guard rails. Onsite measuring, shop cutting with the Type 1 wheel for clean edges, then install. Emphasize sanitary, corrosion-resistant results suited to food and beverage environments.

Minimalist Stainless Hardware Shop

E-commerce or Etsy store selling modern stainless shelf brackets, wall hooks, plant hangers, and address plaques. Use the chop saw for crisp, repeatable cuts and batch production. Offer brushed or mirror finish and custom sizing as an upsell.

Mobile Onsite Cutting & Repair

Bring a chop saw station to client sites (restaurants, marinas, labs) to cut and fit stainless repairs or alterations without contaminating parts. Charge a call-out fee plus per-cut pricing; cross-sell polishing and passivation for a complete service.

Creative

Modern Stainless Outdoor Bench

Build a sleek outdoor bench using 1.5–2 in stainless square tube. Use the chop saw wheel for repeatable, burr-minimized cuts on legs, stretchers, and slats. Weld or bolt together, then blend the joints and finish with Scotch-Brite. The non-contaminating wheel helps keep welds clean and corrosion-resistant for all-weather longevity.

Modular Kitchen Shelving + Pot Rack

Create a modular wall-mounted system from stainless angle and tube. Cut brackets, crossbars, and standoffs to length, then assemble with rivnuts or TIG welds. Add S-hooks for utensils. Stainless plus contamination-free cutting keeps a sanitary, food-safe finish that’s ideal for kitchens.

DIY Cable Railing Posts

Fabricate stainless posts and top rails for a balcony or deck. Cut posts and rail segments precisely on the chop saw, drill cable pass-throughs, and add swaged fittings. The no-iron/sulfur/chlorine wheel preserves stainless integrity for outdoor and coastal installs.

Grillmaster Accessory Set

Cut stainless rod, flat bar, and angle to make skewers, grill grates, a rib rack, and a plancha support frame. The wheel’s clean cut minimizes contamination, making the pieces safer for food contact and easier to clean after high-heat use.

Geometric Wall Art/Trellis Grid

Assemble a hex or diamond grid from stainless rod or flat bar. Chop precise lengths, jig them on a flat surface, and weld/braze. Polish for an indoor art piece or mount outdoors as a vine trellis—the stainless and clean cutting resist rust and staining.