Features

- 0.045 in thin kerf for fast, burr‑reduced cuts

- Temper Point(TM) coated grains for extended cutting life and improved adhesion

- Designed to cut carbon steel, stainless steel and nickel‑based alloys

- Two layers of fiberglass reinforcement for wheel strength and reduced breakage

- High grain concentration for aggressive cutting action

Specifications

| Package Quantity | 25 |

| Wheel Diameter | 4-1/2 in |

| Disc Thickness | 0.045 in |

| Arbor Size | 7/8 in |

| Max Speed | 13,300 rpm |

| Abrasive Material | Aluminum oxide |

| Grit | 60 |

| Disc Type | Flat (Type 1) |

| Intended Use / Applicable Materials | Steel, stainless steel, high‑strength nickel‑based alloys |

Related Tools

Related Articles

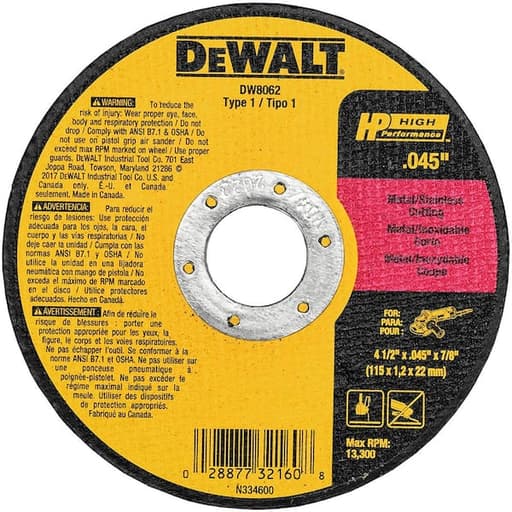

A thin cutting wheel designed for cutting ferrous metals and stainless steel. The wheel uses a proprietary aluminum-oxide grain formulation with improved grain-to-resin adhesion to maintain cutting performance and extend service life. It is reinforced with two layers of fiberglass to increase strength and reduce the risk of breakage.

DeWalt 4-1/2 in. x 0.045 in. x 7/8 in. Metal and Stainless Cutting Wheel (25-Pack) Review

Why these thin cut-off wheels earned a slot in my grinder bag

I ran this 4-1/2 in. by 0.045 in. DeWalt cutting wheel over a couple weeks of real shop work—fabrication, maintenance cuts, and a few on-site trims—using both corded and cordless grinders. The short version: they cut fast, track straight, and hold together well, especially for a thin kerf disc. They’re not the longest-lasting wheels I own, but the balance of speed, cut quality, and predictability makes them an easy reach for day-to-day ferrous work.

Fit, form, and build

- Size and type: 4-1/2 in. diameter, 0.045 in. thick, 7/8 in. arbor, Type 1 (flat).

- Max speed: 13,300 rpm, so they’re happy on typical 4-1/2 in. grinders.

- Abrasive: Aluminum oxide, 60 grit.

- Reinforcement: Two layers of fiberglass.

The thin kerf is the headline. That 0.045 in. profile reduces load on the grinder and leaves a narrow slot, which translates to quick cuts and smaller burrs. DeWalt’s grain is bound with a resin system they say improves grain-to-resin adhesion, and the grains get a Temper Point coating. In practice, that combination kept the wheel from glazing prematurely, especially on stainless, which is often where budget discs die.

The wheels are Type 1 flat, so they require a proper cut-off guard and aren’t meant for any side loading. If you’re used to Type 27 depressed-center wheels for occasional side grinding, plan your setup accordingly—these are for straight-in cutting.

Test setup and materials

I put several of these DW8062 wheels on:

- A 13-amp corded grinder (11,000 rpm no-load).

- A 20V brushless cordless grinder.

Materials included:

- 3/8 in. mild steel angle and 1/4 in. plate.

- 1 in. schedule 40 steel pipe.

- 304 stainless 1/8 in. flat bar and 16-gauge sheet.

- A short run on a scrap of a nickel-based alloy (harder than mild/stainless).

All cuts were dry, with guards in place, consistent feed pressure, and full-speed passes. I avoided lateral twisting to keep test variables clean.

Cutting performance

- Mild steel: The wheels bite quickly and stay on line. On 3/8 in. angle, they pulled a clean cut in short order without bogging the grinder. Kerf accuracy is good; it’s easy to shave to a line without the disc wandering.

- Stainless: On 304, the wheels kept a decent cutting rate and resisted glazing longer than generic aluminum-oxide wheels. If I leaned too hard, heat built up and the wheel smoothed over, but backing off pressure restored bite. Heat tint on the workpiece was minimal with a moderate feed and fresh wheel.

- Nickel alloys: Usable but slower, as expected. The wheel wears faster on tough alloys, but it stayed intact and predictable.

Spark pattern is typical for thin cut-off discs: bright but not excessive. Cut edges needed a quick kiss with a flap disc; burrs were smaller than I usually see with thicker 1/16 in. wheels.

Life, wear pattern, and consistency

A thin wheel is never going to outlast a thicker or ceramic-bonded disc, but these held up well. Wear was even, with no chunking at the rim, and the wheel kept its shape down to a smaller diameter without becoming grabby. On mild steel, I could make multiple cross-cuts on 1/4–3/8 in. stock before the wheel shrank enough to notice a change in feel. On stainless, life drops—as it does with any aluminum-oxide wheel—but the Temper Point-coated grain delayed the usual glazing I get from bargain discs.

Compared head-to-head with premium ceramic options, these DeWalt wheels won’t match the sheer longevity or cool cutting in thicker stainless. Against mid-tier house-brand and off-brand wheels, they outlasted most and cut faster. The standout trait is consistency: I didn’t have to adapt my feed rate from one wheel to the next within the pack.

Stability, safety, and feel

The two fiberglass layers do their job. The wheels feel composed at speed, with minimal startup wobble and no “flop” mid-cut when the rim wears down. I had zero breakages, and no alarming chatter, provided I kept the cut straight and avoided binding. The thin kerf demands respect: any lateral twist or pinched kerf will remind you quickly. Use the cut-off guard, keep your orientation stable, and don’t pry with the disc.

Vibration is low, which helps track a line and keeps fatigue down during a string of cuts. These also run fine on a cordless grinder, where the lower mass of the wheel and thin kerf help conserve battery.

What they’re best at

- Fast cuts on mild steel and thinner stainless sections.

- Trim work where a narrow kerf matters.

- Battery-friendly cutting on cordless grinders.

- Situations where you want a predictable, straight-tracking wheel that won’t chip away unevenly.

Limitations to keep in mind

- Not a side grinder: Type 1 means strictly straight cuts. Any lateral pressure is a no-go.

- Aluminum and soft non-ferrous: They’ll load up quickly. Use a non-ferrous-specific disc for those.

- Heavy stainless production: If you’re living in 1/4 in. stainless all day, a ceramic wheel may be more economical despite higher upfront cost.

- Thin-disc fragility: Store them flat and dry to protect edges. Thin rims are more susceptible to damage from drops or cramped tool bags.

Practical tips for best results

- Let the wheel do the work. Moderate, steady feed keeps the grain sharp and the kerf cool.

- Keep the cut straight. Avoid rocking or steering with side pressure.

- Clamp your work securely and plan an exit. Binding at the end of a cut is where most wheel breaks happen.

- Use full speed. These are rated for common high-rpm grinders; don’t starve them with underpowered tools or weak batteries.

- Dress the edge with a quick flap-disc pass to remove light burrs—these leave little, but a touch-up always helps.

- Rotate through wheels before they get too small for your guard setup. Smaller diameter changes cut geometry and can tempt unsafe angles.

Value and alternatives

In a 25-pack, these DeWalt wheels land in a sensible middle ground: more expensive than no-name bulk discs, less costly than premium ceramic options. Given their speed and consistent life, the per-cut cost comes out favorably for general fab, maintenance, and jobsite use. If your workload is mostly mild steel with occasional stainless, they’re a smart, low-hassle choice. If you specialize in thick stainless or high-nickel alloys, a step up to ceramic-alumina or engineered abrasive wheels will reduce heat and extend life—at a higher price point.

Who will appreciate these wheels

- Fabricators and mechanics who prioritize a quick, straight cut with minimal burrs.

- Maintenance techs and builders who need a reliable, consistent disc in the bag.

- DIYers stepping up from bargain discs looking for a noticeable improvement without going premium-ceramic.

The bottom line

I like these DeWalt wheels for the same reason I like a well-tuned grinder: they make cutting feel controlled. The thin kerf speeds the work, the grain stays cutting longer than typical aluminum-oxide discs, and the reinforced build inspires confidence as long as you respect the rules of a Type 1 wheel. They’re not the longest-wearing in the world, but the combination of speed, cut quality, and consistency adds up to solid value.

Recommendation: I recommend these for anyone doing regular cutting on carbon steel and light-to-moderate stainless, especially if you appreciate a fast, clean kerf and predictable behavior across a full pack. If your shop lives in thick stainless or exotic alloys all day, consider a ceramic wheel for heat control and longer life; otherwise, these strike a very good balance for everyday ferrous work.

Project Ideas

Business

On-Site Metal Cutting and Removal

Offer a mobile service to cut bolts, rusted fasteners, stainless handrails, rebar, and small pipe where torches aren’t practical. Bill per hour plus consumables. The 25‑pack ensures you can handle dense stainless and nickel alloys without downtime.

Custom Brackets and Tabs Same-Day

Provide rapid-turn brackets, gussets, and tabs for contractors and makers. Cut parts from flat bar and sheet with tight tolerances thanks to the thin kerf, then deburr and deliver same-day. Upsell drilling and welding for ready-to-install hardware.

Stainless Restaurant Fit-Out/Repair

Specialize in cutting and fitting stainless splash guards, shelves, and equipment panels for commercial kitchens. The wheel’s stainless capability minimizes heat tint and contamination, enabling clean field modifications and emergency repairs.

Boutique Metal Wall Art Shop

Produce small-batch silhouettes, monograms, and nature scenes in carbon steel and stainless for Etsy and local markets. The thin kerf reduces post-grind time, boosting throughput. Offer custom sizing and finishes to command higher margins.

Mobile Address and Signage Service

Design and cut house numbers, mailbox plates, and small business signs on-site or in a pop-up shop. Fast, burr-reduced cuts speed installation. Pair with powder coating or brushed finishes and offer mounting hardware as a package.

Creative

City Skyline Silhouette Panel

Transfer a skyline outline to thin stainless or mild steel sheet and cut it out with the 0.045 in thin-kerf wheel for crisp detail and minimal burrs. Add standoffs for a shadow effect and finish with brushed or heat-patina accents. The wheel’s fiberglass reinforcement helps with longer, continuous contour cuts without chatter.

Kinetic Stainless Wind Spinner

Cut concentric rings and tapered vanes from stainless sheet, then twist and space them on a central shaft to create a wind spinner that catches light. The thin kerf keeps gaps even and reduces cleanup, while the wheel’s stainless-rated abrasive avoids contamination and burn marks.

Modern House Numbers and Sign Plate

Cut sleek numerals or a family name from 304 stainless or carbon steel plate. Use the thin kerf for tight inside corners and cleaner edges, then brush, blacken, or powder coat. Mount on a contrasting backer with stand-offs for a premium architectural look.

Modular Geometric Planters

Rip and miter cut strips of mild steel to form hexagons and triangles, then weld into faceted planters. The wheel’s fast cut speeds up repetitive angle cuts and keeps gaps tight so welds are neater. Seal with clear coat or let them develop a natural patina.

Upcycled Industrial Coat Rack

Cut sections of rebar, old wrenches, or bike chain and mount them to a steel backplate for hooks. The wheel slices hard alloys cleanly, and the thin kerf preserves the character of the salvaged pieces. Finish with beeswax or a matte clear to highlight the metal.