Features

- Includes two outer blades plus multiple chippers, spacers and shims for variable groove widths

- Micro-grain carbide teeth are resharpenable and reduce splintering

- Four-tooth chippers produce flat-bottom cuts

- Stainless steel shims allow fine width adjustments

- Heavy-gauge, laser-cut plates for accurate cuts

- Heat-resistant, non-stick coating on blades

- Heavy-duty storage case to protect blades

Specifications

| Arbor Size | 5/8 in |

| Product Diameter | 8 in |

| Tooth/Hook Angle | -12° |

| Groove Capacity | 1/4 in to 7/8 in |

| Included Components | 2 outer blades, 3 chippers, 3 spacers, 7 shims |

| Teeth Material | Micro-grain carbide (oversize, resharpenable) |

| Coating | Heat-resistant, non-stick |

| Compatible Materials | Softwood, hardwood, plywood, melamine |

| Warranty | No limited warranty (product not eligible) |

Related Tools

Related Articles

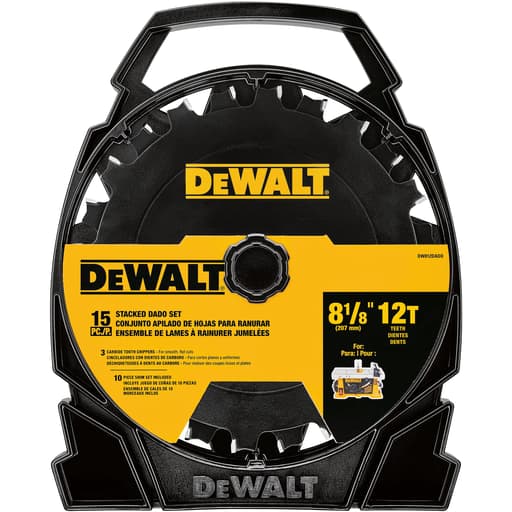

A stacked dado set composed of two outer blades, multiple chippers, spacers and shims. It is intended for cutting grooves (dadoes) in wood and wood-based panels. The blades have resharpenable carbide teeth and a heat-resistant, non-stick coating. The set is supplied with a storage case.

DeWalt Stacked Dado Set Review

First impressions and setup

I put the DeWalt dado set on my table saw for a week’s worth of cabinet and trim work—oak plywood shelves, a run of melamine carcass parts, and a batch of softwood shiplap. Out of the case, the components feel substantial. The outer blades and chippers are cut from heavy-gauge plates and the micro‑grain carbide is generous enough to invite resharpening when the time comes. The heat‑resistant, non‑stick coating is well applied and arrived clean with no overspray on the bores. Everything nests neatly in the included case, which is tough enough to live in a truck without the stack coming loose.

The set includes two outer blades, three chippers, spacers, and a selection of stainless shims. With a 5/8 in arbor and 8 in diameter, it fits the most common table saws, but as always, you’ll need a compatible dado throat plate and to remove the riving knife or guard. The published hook angle is -12°, which is a good choice for controlling feed and reducing tear-out, especially on plywood and melamine.

One practical note: there’s no limited warranty. If you expect a backstop from the manufacturer for consumables like this, you won’t find it here.

Dialing in widths

Stacked dado sets live or die by how easily they dial to a target width. With this set, I measured repeatable widths by stacking the chippers and spacers to the closest nominal size, then fine‑tuning with the thin stainless shims. I started with common tasks: a 1/4 in groove for drawer bottoms, a 23/32 in groove for “3/4 in” plywood, and a 3/8 in dado for partition dividers.

- The 1/4 in stack landed just shy of 0.250 in on my calipers; a single shim brought it dead on.

- The 23/32 in setup required a bit of trial, as typical—it’s the reason shims exist. Two thin shims plus a spacer got me to 0.718 in within a thousandth.

- The 3/8 in dado was straightforward with one chipper and a thin shim.

There are only three chippers, which means you’ll use shims more often than on premium sets with five or six chippers. That’s not a deal‑breaker, but it does add a few minutes when you’re bouncing between widths. My advice: keep a cheat sheet of shim combos once you’ve dialed in common sizes. Labeling your shims with a fine marker also speeds things up.

Cut quality and flatness

On hardwood and plywood, the cut quality was consistently good. The four‑tooth chippers left flat bottoms with clean walls, and I saw minimal “bat ears” at the shoulders—faint scoring ridges were visible on light‑colored maple if I went looking for them with raking light, but they were shallow enough to disappear under glue or a pass with a cabinet scraper.

- Oak plywood: With the blade height set just a hair above the veneer thickness and a zero‑clearance dado insert, I got crisp shoulders and no meaningful tear‑out on the cross‑grain cuts. The negative hook angle helps here, keeping the cut controlled rather than grabby.

- Melamine: The coating plus negative hook yielded better‑than‑average edges. I still used a sacrificial fence and light feed; the results were serviceable for shop cabinets without any edge banding.

- Hard maple: Dead‑flat bottoms, no chip‑out, and a nice smooth surface that glued up cleanly.

I checked flatness by placing a straightedge across the dado bottoms and measuring with feeler gauges. The bottoms were flat within a few thousandths across the width of the cuts. That speaks to the chipper grind and plate rigidity. I didn’t see the center riding high or low relative to the outers once the arbor nut was properly torqued and the stack assembled clean of dust.

Softwood behavior and feed sensitivity

Softwoods are always a harder test for cross‑grain dadoes because the earlywood can crush. In radiata pine and construction‑grade SPF, the cut quality depended on feed rate and support. Pushing too fast, I could coax a little fuzzing on the exit side of the cut and some bruising along the shoulders. With a backer board, steady feed, and a slightly lower blade height, the shoulders cleaned up. If you routinely run soft, knotty stock for visible joinery, plan on a light sanding or a scribe to pre‑score the shoulders for the best results.

I wouldn’t call the set aggressive; the -12° hook keeps it composed. But like any stacked dado, it rewards a calm feed and well‑supported work.

Accuracy, vibration, and power

Stack concentricity seemed solid. I measured runout at the rim with a dial indicator and saw less than 0.003 in on my cabinet saw, which is in the pocket for this class. On a smaller jobsite saw, the stack still ran smoothly with no alarming vibration, though you’ll feel the increased load compared to a single blade. The negative hook helps avoid bogging on lower‑power saws, but you still need a sharp stack and a clean fence. The heavy plates and laser‑cut bodies also help with stability—there’s a different sound to a rigid stack, and this one runs with a pleasing hum rather than a chatter.

Real‑world tasks

A few projects put it through its paces:

- 23/32 in shelf dados in oak plywood: Factory‑faced panels, no tape, just a zero‑clearance insert. Results were crisp, and the shelves dropped in with a gentle hand‑pressure fit.

- 1/2 in lap joints in poplar: Flat bottoms and tight shoulders, no noticeable gaps. Glue squeeze‑out cleaned easily thanks to the smooth surface left by the carbide.

- Shiplap in soft pine: After dialing the rabbet to 3/8 x 3/8 in, the stack cut clean laps with only minor fuzzing on the trailing edges—easily knocked off with a sanding block.

Maintenance and longevity

Micro‑grain carbide that’s intentionally oversize is a plus; it gives you room for multiple sharpenings. After a week of work, the edges still felt crisp. Resin didn’t build on the coated plates like it does on uncoated steel, and what little did accumulate wiped off with citrus cleaner. I appreciate that the stainless shims don’t kink easily, and the storage case actually protects the teeth rather than just corralling parts. Labeling the pockets for each component would make it even better, but that’s nitpicking.

Where it comes up short

- Limited chipper count: With only three chippers, you’ll do more shim work to land odd sizes. It’s not hard, just slower.

- No included fine‑tuning chart: You’re on your own to map shim combos for common plywood sizes. I keep notes; you should too.

- No limited warranty: Not unusual for cutting tools, but worth noting.

- Softwood sensitivity: On very soft or knotty stock, expect to work a little to prevent fuzzing—use a backer, lower the blade height, and manage your feed.

I didn’t encounter uneven depth across the stack or obvious quality control issues on my set. As with any dado stack, a dirty arbor, a stray chip, or an under‑torqued nut can mimic those problems. Take the time to clean, assemble carefully, and recheck torque after the first test cut.

Who will like it

If you build cabinets, shelves, and built‑ins, this dado set hits a sweet spot. It’s accurate, leaves flat bottoms, and behaves well on veneered panels and hardwoods. Woodworkers who value resharpenable carbide and a tidy case will appreciate the long‑term usability. If you’re production‑minded and constantly change widths, the shim‑heavy workflow may slow you down. And if you primarily work in soft construction lumber for visible joinery, you’ll need to pair it with good workholding and technique to get showcase‑ready edges.

Recommendation

I recommend the DeWalt dado set for woodworkers who want a dependable, flat‑cutting stack that excels on hardwoods, plywood, and melamine, and who don’t mind spending a few extra minutes with shims to nail exact widths. The build quality, negative hook geometry, and resharpenable carbide deliver clean, controlled cuts with low vibration. Its main drawbacks are the limited number of chippers, the lack of a warranty, and a bit of fussiness on softwoods. If those trade‑offs fit your workflow, it’s a solid, long‑term addition to the shop.

Project Ideas

Business

Cabinet Carcass Prep Service

Offer pre-dadoed cabinet parts for local woodworkers and remodelers. Use precisely sized 1/4 in, 1/2 in, and 3/4 in grooves and rabbets for toe kicks, backs, partitions, and drawer bottoms. The resharpenable carbide teeth and shims let you match undersized sheet goods exactly, reducing assembly time for clients. Bill per sheet or per cabinet box.

Custom Closet and Garage Systems

Produce modular closet towers, shelves, and drawer units in melamine or plywood. Clean, chip-free grooves for adjustable shelves and captured backs give a factory look. Add slatwall panels and French-cleat accessories for garages. Sell as installed systems or flat-pack kits with labeled, dadoed parts for easy DIY assembly.

Drawer Box Production

Batch-produce drawer boxes with quick, strong joinery. Use 1/4 in grooves for bottoms and 1/2–3/4 in rabbets/dados for front and back joinery. The flat-bottom cuts improve glue adhesion and speed assembly. Offer custom sizing to cabinet shops and furniture makers with fast turnaround and volume pricing.

Flat-Pack Furniture Kits

Design knock-down bookshelves, record crates, and side tables that key together with accurately sized dados and rabbets. The heavy-gauge, laser-cut plates keep tolerances tight so customers get a satisfying press-fit. Include hardware, finish options, and clear instructions; sell online and at maker markets.

Retail/Display Fabrication

Build point-of-sale stands and display panels with integrated slatwall grooves and sign channels. The adjustable groove width (1/4–7/8 in) lets you fit various track systems and acrylic inserts. Market to boutiques, pop-up shops, and trade show vendors needing custom-branded displays on short lead times.

Creative

Adjustable Bookcase with Captured Back

Build a plywood bookcase with stopped 3/4 in dados for shelves and a 1/4 in groove for a back panel. Use the chippers and stainless shims to tune exact shelf groove widths to undersized plywood. Cut a rabbet on the case edges for a flush back, and use the flat-bottom cut to maximize glue surface and strength. The heat-resistant coating helps when cutting long runs in hardwood or melamine without pitch buildup.

Sliding-Door Credenza

Create a media console with twin sliding doors. Use 1/4 in and 3/8 in grooves as upper and lower door tracks, and 1/2–3/4 in dados for internal dividers. The four-tooth chippers leave flat, smooth bottoms so doors glide well. Micro‑grain carbide teeth minimize splintering on plywood or melamine faces for clean, visible tracks.

Garage Slatwall Panels

Make custom slatwall by batching evenly spaced horizontal grooves across sheet goods. Set the dado stack to 3/4 in (within the 1/4–7/8 in capacity) and cut shallow, consistent grooves sized for hooks or aluminum inserts. A simple spacing jig plus the laser-cut plates ensure accurate, repeatable spacing. Use melamine or MDF for a professional retail-style wall.

Inlaid Chessboard Serving Tray

Laminate a maple panel, then cut a grid of 1/4 in flat-bottom grooves to accept contrasting walnut strips for crisp inlays. After gluing the strips, crosscut perpendicular grooves to complete the checkerboard. Add a 3/8 in rabbet for a captured bottom panel and integral handholds. The precise, flat dados make the inlay lines tight and seamless.

Picture Frames with Rabbets and Splines

Mill frame stock, then cut a 3/8 in deep rabbet for glass and backer using part of the dado stack. Reinforce mitered corners with spline slots cut using the flat-bottom set for maximum glue area. The negative hook angle helps reduce blowout on fragile end grain and veneered stock.