Features

- X-LOCK snap-on mount for tool-free wheel changes

- Aluminum oxide abrasive, 30 grit

- Resinoid (resin) bond reinforced with fiberglass for durability

- Designed for metal cutting and grinding (aluminum, non‑ferrous metal, steel)

- Tool-free disc swap — no spanner wrench or flange nuts required

- Maximum recommended speed: 13,280 RPM

Specifications

| Wheel Type | Type 27A (ISO 42) |

| Diameter | 4-1/2 in (114 mm) |

| Thickness | 1/8 in (0.125 in / 3.175 mm) |

| Arbor | X-LOCK (7/8 in / 0.875 in) |

| Grit | 30 |

| Abrasive Material | Aluminum oxide |

| Bond Type | Resinoid / resin (fiberglass-reinforced) |

| Intended Cut Materials | Aluminum, non‑ferrous metals, steel, metal profiles |

| Mount | X-LOCK quick-change (snap-on) |

| Maximum Rpm | 13,280 |

| Sku | CWX27LM450 |

| Pack Quantity | 1 |

Related Articles

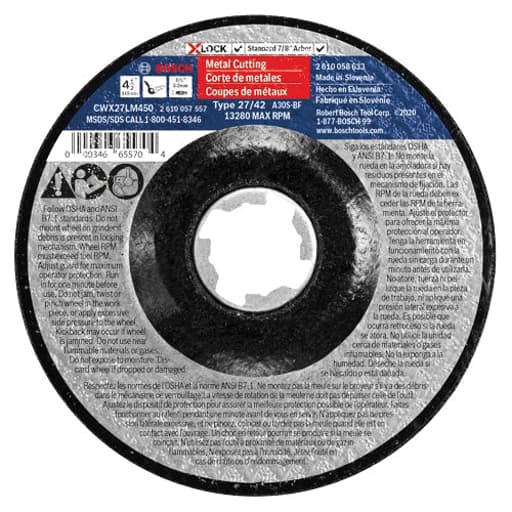

Type 27A X-LOCK small angle grinder wheel for metal cutting and grinding. 4-1/2 inch diameter, 1/8 inch thickness, 7/8 inch arbor. Uses 30-grit aluminum oxide abrasive in a resinoid (resin) bond reinforced with fiberglass. Designed for use on X-LOCK grinders with snap-on, tool-free mounting. Intended for cutting and grinding aluminum, non‑ferrous metals and steel. Contains California Proposition 65 warning.

Bosch Small angle grinder wheel, Type 27A (ISO 42), 4-1/2 in × 1/8 in, X-LOCK, 30 grit Review

Why I reached for this wheel

On a recent fabrication day, I needed one wheel that could bounce between rough cuts and quick touch-up grinding without constantly digging for a spanner wrench. I put Bosch’s X-LOCK 4-1/2-inch combo wheel on my grinder and kept it there for the better part of the afternoon. It’s a Type 27A, 1/8-inch-thick, 30-grit aluminum oxide wheel built for both cutting and grinding. In short: a utility player. Here’s how it fared across steel and aluminum, what stood out, and where I’d reach for something else.

Setup and mounting

X-LOCK is the headline feature. Snap the wheel onto the grinder’s flange, give it a press until it clicks, and you’re ready. No flange nuts, no spanner, no fuss when switching tasks or swapping wheels. The mechanism is fast and secure; I never had slippage or a half-seated mount. If you’re juggling a cut-off, a combo wheel, and a flap disc in the same session, that time savings adds up. The wheel is rated to 13,280 RPM, so it’s a match for most 4-1/2-inch grinders.

A quick note on compatibility: this wheel is designed for X-LOCK grinders. While the center bore is 7/8 inch, I stick to using it on X-LOCK tools as intended and recommend following Bosch’s guidance on accessory compatibility and guards.

Cutting performance

I ran the wheel through:

- 3/16-inch mild steel flat stock

- 1/4-inch aluminum plate and 1-1/2-inch aluminum angle

- 1/2-inch rebar

- A handful of steel profiles for trimming to length

At 1/8 inch thick, this isn’t a thin cut-off disc. The kerf is wider, and cuts are slightly slower than with a 0.045-inch wheel. The trade-off is stability: the wheel tracks straighter, resists binding better when your angle wanders, and tolerates light lateral pressure without chattering. On rebar and steel angle, it was predictable and easy to keep on line. Heat management is decent; I saw a normal straw-to-blue heat tint on steel when pushing hard, but nothing excessive.

Aluminum is where a lot of general-purpose wheels stumble because of loading. This one is billed for aluminum and non-ferrous metals, and it held up better than many standard AO wheels. If I leaned too hard, it would start to smear and load, but backing off to lighter pressure restored cutting efficiency. A quick pass on a dressing stick or a swipe of wax stick kept it happy during longer aluminum cuts. If your day is mostly aluminum, a dedicated non-ferrous composition wheel will still be faster, but this gets the job done without constant clogging.

Edge quality reflects the 30-grit spec. Cuts are coarse, with a burr that needs a follow-up pass. That’s expected at this grit and thickness; I wouldn’t choose this for delicate sheet metal or finished edges.

Grinding and beveling

As a Type 27A depressed-center wheel, it’s designed for both cutting and surface contact at an angle. For cleanup and light grinding, it’s competent. I used it to:

- Knock back light weld spatter

- Break edges after cutting

- Rough in 45-degree bevels on steel before welding

The 1/8-inch thickness gives a stable footprint that’s less grabby than a thin cut-off wheel if you tilt it into the work. Compared to a flap disc, the finish is rougher and heat builds more quickly, but for quick chamfers or knocking down edges, it’s perfectly serviceable. If I need a smooth blend or a paint-ready surface, I’ll switch to a flap disc; if I’m prepping for weld, this wheel’s aggressive bite is an advantage.

Feel, balance, and control

The wheel feels true out of the box. No noticeable vibration or wobble, which helps maintain a straight cut and reduces fatigue. The fiberglass-reinforced resin bond contributes to a solid feel when you need to side-load lightly during trimming. Combined with the X-LOCK’s positive mount, the overall system feels secure and predictable.

Noise and sparks are typical for a 30-grit AO wheel on steel. On aluminum, it runs quieter, with the usual fine particulate instead of a spark stream. Use a guard and dust extraction or PPE as you would expect; the product carries a California Proposition 65 warning like many abrasives.

Wheel life

Wheel wear was very reasonable for the class. After a series of cuts in mild steel and several passes on aluminum, I saw consistent, even wear with no glazing. As a thicker wheel, it outlasts thin cut-offs in mixed-use scenarios, especially when you shift between cutting and quick face grinding. If your work is almost exclusively straight cutting on steel, a thinner wheel will be faster and still deliver good life. If your day is a back-and-forth between cuts and edge work, this combo wheel is the more economical choice because you’re not chewing through delicate cut-off discs while side-loading.

Material-specific notes

- Mild steel: Strong performer. Tracks straight, resists binding, and holds up under moderate pressure. Expect a burr.

- Aluminum and non-ferrous: Better-than-average loading resistance for an AO wheel. Keep pressure light, consider a wax stick, and give it a quick dress if you notice smearing.

- Stainless: It cuts, but this isn’t a dedicated INOX wheel. For stainless or heat-sensitive alloys, I prefer a wheel formulated without iron/sulfur/chlorine and often a tougher abrasive like zirconia or ceramic.

Where it shines

- X-LOCK convenience: Snap-on changes keep the workflow moving, especially when alternating between cutting and grinding tasks.

- Stability for combo use: The 1/8-inch thickness is forgiving and confidence-inspiring when you need to both cut and then clean up the cut.

- Mixed-material days: If you’re bouncing between aluminum and steel, this wheel plays nicely with both.

Where it’s not the best fit

- Fine, fast cuts: For thin kerf and speed on steel, a 0.045-inch cut-off disc is still king.

- Finish work: For a cleaner surface or blended edges, a flap disc or finer grit wheel is better.

- Dedicated stainless work: A stainless-rated wheel will run cooler and last longer on that material.

Durability and value

Within its category—aluminum oxide, 30 grit, combo profile—the durability is solid. It wears predictably, doesn’t chip easily under reasonable side load, and the bond feels tough without being brittle. If you factor in the time saved by not hunting for a spanner and not swapping between single-purpose discs every 10 minutes, the overall value is high on an X-LOCK grinder. Pack quantity is one, which makes sense for a general-purpose wheel you’ll try before committing to a multi-pack.

Safety and best practices

- Match your grinder’s RPM to the wheel’s 13,280 max rating or lower.

- Use the proper guard for Type 27 wheels.

- Keep pressure modest on aluminum to avoid loading; dress or wax as needed.

- Let the wheel do the work—especially on cuts—to keep heat and wear in check.

The bottom line

I like this Bosch X-LOCK combo wheel for days when I need one abrasive to cover cutting and light grinding across both steel and aluminum. The snap-on mount speeds up the work, the 1/8-inch profile lends stability you don’t get from thin cut-offs, and the 30-grit bite is effective for prep and rough shaping. It won’t replace a thin kerf disc for precision cuts, a flap disc for finish work, or a dedicated stainless wheel, but it’s a reliable middle-ground that reduces accessory changes and headaches.

Recommendation: I recommend this wheel if you run an X-LOCK grinder and want a dependable, general-purpose disc that can handle both cuts and quick cleanup on mixed metals. It’s not the fastest cutter or the smoothest finisher, but as a single wheel that simplifies the job and stays predictable under real-world use, it earns a spot in the kit.

Project Ideas

Business

Same‑Day Custom Brackets

Offer a micro‑fabrication service for custom steel or aluminum brackets, tabs, and gussets. The X‑LOCK quick changes keep throughput high: measure, cut, deburr, and ship or deliver locally within 24 hours. Market to contractors, makers, and repair shops.

Mobile Railing and Gate Repairs

Provide on‑site cutting and grinding to remove rusted sections, trim misfit hinges, and replace pickets. The 1/8‑inch wheel handles both cutting and light blending, minimizing gear. Bill a call‑out fee plus hourly labor and materials.

Event/Sign Frames and Stands

Build lightweight steel frames, banner stands, and sign bases for events and storefronts. Quick, clean cuts and edge finishing help deliver polished pieces fast. Offer rental inventory and custom branding upsells.

Upcycled Metal Decor Shop

Turn salvage into sellable art: wall pieces, planters, bookends, and candle holders. Use the grinder to cut, silhouette, and surface-finish. Sell through Etsy, local markets, and wholesale to boutiques with limited edition drops.

Moto/Auto Tabs and Mounts

Fabricate battery trays, radiator brackets, light mounts, and exhaust hangers for custom motorcycle and auto builds. Provide template-to-part service: customers send a cardboard template; you cut, finish, and ship laser‑clean equivalents using grinder‑jig workflows.

Creative

Scrap-Steel Wall Art Panels

Cut abstract shapes and negative spaces from scrap steel sheet, then use the 30‑grit wheel to bevel edges and add grind textures and directional patterns that catch light. Arrange and stitch-weld pieces onto a backer frame, clear-coat to preserve the raw industrial look.

Geometric Garden Trellis

Cut steel flat bar and rod into triangles/diamonds, then lightly grind the joints for a clean fit before welding. Use the wheel to round corners and break sharp edges so plants won’t snag. Powder coat or paint for a modern, durable garden feature.

Portable Fire Pit Ring

Cut segments from mild steel sheet to form a ring or faceted bowl. Use the depressed‑center wheel to blend seams and chamfer the rim. Add cutout motifs (stars, mountains, initials) and grind smooth for a crisp silhouette that glows when lit.

Upcycled Wood-and-Steel Side Table

Fabricate a minimalist steel base from angle and flat bar: cut to length, miter corners, and grind welds flush for a seamless look. Pair with a reclaimed wood slab top. Finish the steel with a brushed grind pattern and clear coat for contrast.

Aluminum Wind Chimes

Cut aluminum tube and flat strip into tuned lengths. Lightly grind and deburr ends for a clean ring and safe edges. Create a small steel or aluminum hanger with decorative cutouts, then suspend the tubes with fishing line or chain.