Features

- Coarse crimped carbon steel wire for aggressive material removal

- Heat‑treated, high‑tensile wire construction for durability

- 3‑inch diameter

- 1/4‑inch shank (arbor compatible with NO 10‑32)

- Suitable for removing paint and rust and for metal finishing/polishing

- Includes one wire wheel

Specifications

| Manufacturer | Black and Decker |

| Mpn | 70-603 |

| Diameter | 3 in |

| Shank Diameter | 1/4 in |

| Arbor Size | No. 10-32 |

| Wire Material | Heat‑treated high‑tensile carbon steel |

| Wire Style | Crimped, coarse |

| Suitable Materials | Wood, metal, plastic |

| Intended Use | Rust and paint removal; surface preparation; metal finishing |

| Product Weight | 0.2 lb (product) - 0.70 lb (shipping record) |

| Product Dimensions | Height 1.6 in; Length 6.9 in; Width 4.3 in |

| Shipping Dimensions | 7.2 in x 3.5 in x 4.5 in |

| Includes | (1) Wire Wheel |

Related Tools

Related Articles

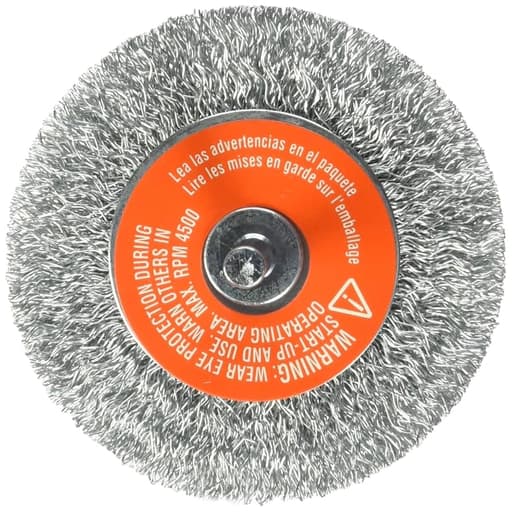

3-inch diameter crimped wire wheel with a coarse wire pattern designed for surface preparation tasks such as removing paint, rust, and other materials from wood, metal, and plastic. Constructed from heat‑treated, high‑tensile carbon steel for extended brushing action and durability. Intended for use on compatible rotary tools or grinders.

Black & Decker Wire Wheel, 1/4-Inch Crimped, Coarse Shank, 3-Inch Review

Why I reached for this wire wheel

I keep a small arsenal of wheels and brushes for cleanup work, and a 3-inch crimped wire wheel is one of those staples I burn through regularly. I picked up this Black & Decker 3-inch wire wheel for a round of surface prep—rusty outdoor hardware, a paint-caked steel bracket, and a couple of small fixtures that needed fresh primer. I also put it to work on a weathered metal porch swing to see how it handled a bigger task. Over a few sessions, I learned where this wheel shines, where it struggles, and how to get the most out of it.

Setup and compatibility

The wheel mounts via a 1/4-inch shank, so it drops right into a standard drill chuck or a die grinder with a 1/4-inch collet. The package notes compatibility with No. 10-32 arbors/mandrels; I just ran it directly in a corded drill and a compact cordless drill. That shank makes it broadly compatible and easy to swap between tools, though it’s not intended for a threaded angle grinder spindle. If you’re used to knotted-cup wheels on a 4-1/2-inch grinder, think of this as a lighter-duty option aimed at drills and rotary tools.

A quick tip from setup: seat the shank fully and check for runout by spinning the drill at low speed before you touch the work. Any wobble you see at low speed only gets worse at higher RPMs and will show up as chatter on your surface.

Build quality and design

This is a coarse, crimped carbon steel wheel. The heat-treated, high-tensile wire gives it some backbone, but the crimped pattern means the filaments flex around contours rather than gouging like a knotted wheel might. At 3 inches in diameter, it’s small enough to get into corners and around curves but still covers useful ground on flat bar or tubing. The wheel is relatively light, which helps keep drills comfortable during longer runs.

Overall, the build is what I expect from a mainstream shop consumable. The wires were evenly distributed and the hub ran true out of the package. After several hours of intermittent use, I had the normal flare and slight splaying at the edges you get as crimped wire breaks in.

Performance on rust and paint

Rust removal on steel: On the porch swing’s tubular steel and a stack of rusty brackets, the wheel cut oxidation quickly without digging trenches. It leaves a uniform scratch pattern—aggressive enough to bite through scale but fine enough to be a good base for primer. On heavier flaking rust, I knocked loose scale with a scraper first, then let the wheel bring it to bright metal.

Paint removal: On older alkyd paint, the wheel chewed through the brittle layers fast. On more elastic, modern coatings, it still worked but benefited from a slower drill speed and a light touch to keep the paint from smearing. It’s best on thin to moderate coatings; if you’re stripping thick, layered paint over large panels, a chemical stripper or a larger cup brush will be more efficient.

Edges and corners: The crimped wire flexed nicely around round stock and angle iron. I could roll the brush onto an inside corner at about a 15–20° angle and clean the fillet without digging into adjacent faces.

Wood and plastic: I tested it on paint over softwood and on a scuffed plastic plant stand. On wood, it removes paint, but it also raises grain quickly and can leave wire tracks if you dwell. I’d use it on wood only when you plan to sand afterward. On plastic, it will abrade the surface and can heat the material; keep your passes light and brief if you go there at all.

Control and technique

A few habits helped me get consistent results:

- Run moderate speed with a drill; you don’t need full trigger to cut well with a coarse wheel.

- Use the edge of the wheel at a shallow angle rather than the face; it’s more controllable and prolongs the wire life.

- Let the wheel do the work. If you lean on it, you’ll shed wires faster and glaze your work.

- Make overlapping passes and check your scratch pattern under raking light; if it looks streaky, reduce speed and lighten pressure.

In terms of balance, the wheel felt smooth in both my corded and cordless drills. I didn’t notice excessive vibration until the wires started to flare late in its life, which is typical.

Durability and wear

Heat-treated, high-tensile carbon steel isn’t marketing fluff here—it matters. This wheel held its shape better than bargain-bin brushes I’ve used, especially during extended sessions on scaled rust. Wire shedding was modest early on, then increased as the ends work-hardened and fractured with use. That is normal behavior for crimped wheels.

Lifespan will vary with pressure and speed, but after restoring the porch swing and cleaning a handful of brackets and fasteners, I still had usable wire length left. The diameter decreases over time as the wire tips break, which slightly reduces aggressiveness but can actually make the finish more uniform for final passes.

Safety considerations

Wire wheels do their job by sacrificing wire over time, so eye protection is non-negotiable. I also wear gloves, long sleeves, and keep a magnet handy to collect stray filaments from the bench. With a drill, brace the work and consider a side handle if your drill accepts one; a snag can generate a quick reaction torque. Keep an eye on heat—if the workpiece gets too hot to touch, pause and let it cool.

Where it fits in a kit

Best for: Rust and paint removal on small to medium-sized steel parts, prepping welds for primer, cleaning hardware, and touching up tubing, brackets, and railings.

Acceptable for: Scuffing finishes prior to painting, removing light corrosion on nonferrous metals, selective paint removal on wood when followed by sanding.

Not ideal for: Large flat surfaces where a wider cup brush or flap disc is faster; precision finishing where you need a fine scratch pattern; plastics that are heat-sensitive.

If you need maximum aggression, a knotted wire wheel on a grinder is still king—but it’s also more likely to gouge and is harder to control on delicate profiles. This crimped wheel strikes a good balance: aggressive enough to be productive, compliant enough to be forgiving.

Value and alternatives

This wheel sits in the sweet spot for general-purpose shop work: 3-inch diameter, 1/4-inch shank, coarse crimped wire. You can find cheaper import wheels, but they often arrive out of balance or shed wires prematurely. You can also buy premium stainless-wire wheels if you’re working on stainless steel to avoid contamination; this one is carbon steel, so I reserve it for carbon steel and general cleanup, not stainless or food-grade work.

The single-piece packaging keeps things simple, and at roughly 0.2 pounds it won’t make your drill nose-heavy. I’d keep two in the drawer—one for roughing, one that’s partially worn and a bit kinder for final prep.

Limitations to note

- It’s not a polishing tool despite the “finishing/polishing” label; think of it as surface prep. For a polish-like finish, step down to finer abrasives after this wheel.

- The 1/4-inch shank isn’t for angle grinders; if your workflow lives on a grinder, look for a cup or wheel sized for that tool.

- On wood and plastic, proceed cautiously; it removes coatings, but you’ll be doing additional sanding or cleanup afterward.

None of those are faults so much as the nature of crimped wire wheels, but they’re worth keeping in mind to pick the right tool for the job.

Bottom line

After running this 3-inch wire wheel through a mix of rust, paint, and general surface prep, I’m satisfied with how it performs. It mounts easily in common drills, runs smoothly, removes material at a productive pace, and holds up respectably thanks to the heat-treated carbon steel wire. The coarse crimped design gives you aggression without the harshness of a knotted wheel, which keeps it versatile across curved and irregular workpieces.

Recommendation: I recommend this wire wheel if you need a general-purpose brush for rust and paint removal with a drill or rotary tool. It’s a practical, durable choice for small to medium cleanup tasks, and it leaves a consistent prep surface for primer or further finishing. If you’re tackling broad, flat surfaces or need grinder-level aggression, choose a larger, knotted wheel instead; otherwise, this one earns a spot in the everyday kit.

Project Ideas

Business

Small-Part Rust & Paint Removal Service

Offer fast turnaround cleaning for hinges, brackets, motorcycle/bicycle parts, garden hardware, and hand tools using the 3-inch wire wheel on a drill or bench motor. Price per item set or by batch weight. Upsell: zinc primer, clear-coat, or blackening to prevent flash rust. Partner with local auto/moto clubs and property managers.

Wire-Brushed Texture Wood Finishing

Specialize in raised-grain finishes for mantels, shelves, beams, cabinet doors, and accent walls. Provide sample boards (light, medium, heavy texture) and finish options (stain, liming wax, hardwax oil). Market to interior designers, builders, and Airbnb hosts seeking rustic/industrial looks.

Vintage Tool Restoration & Resale

Source rusty hand tools from estate sales and auctions. Use the wire wheel to remove corrosion, preserve patina, and reveal maker’s marks. Sharpen, oil wooden handles, and photograph well. Sell curated sets on Etsy/eBay with before/after shots. Bundle with maintenance kits for higher margins.

Fabrication Prep Subcontractor

Provide surface prep to small weld/fab shops: remove mill scale, weld spatter, and edge rust from brackets and frames before paint or powder coat. Offer per-part pricing and 24–48 hr turnaround. Document consistency with simple QC sheets and photos to become their go-to prep partner.

On-Site Metal Hardware Refresh

Mobile service for homeowners and HOAs: clean and refresh rusted railings, gate hardware, outdoor furniture frames, and mailbox posts. Use the wire wheel for rapid material removal, then apply rust converter and enamel. Flat-rate per fixture with seasonal maintenance plans.

Creative

Layer-Brushed Metal Wall Art

Create abstract wall panels from scrap steel or aluminum plates. Use the 3-inch crimped wire wheel in overlapping passes to lay directional brush patterns that catch light (sunburst, crosshatch, or concentric rings). Mask sections with tape to vary sheen, then degrease and clear-coat. Mount panels with stand-offs for a floating, gallery look.

Raised-Grain Rustic Shelves

Wire-brush softwoods like pine or fir to erode earlywood and raise grain for a driftwood effect. Stain, wipe back to highlight texture, and seal. Add black pipe brackets for industrial flair. Works for mantels, picture frames, or headboard slats.

Upcycled Garden Tool Sculpture

Collect rusty spades, trowels, and pruners. Strip rust and flaking paint with the coarse wire wheel to reveal mixed metal tones. Arrange and weld or bolt pieces into insect, bird, or kinetic sculptures. Finish with outdoor clear enamel to slow future rust.

Distressed Vintage Signs

Paint a base color on wood or thin sheet metal, apply lettering/stencils, then selectively remove top layers with the wire wheel to expose undercoats and raw substrate for an authentic aged look. Seal with matte clear. Great for retro logos or local maps.

Brushed Metal Photo Frames

Cut thin sheet steel/aluminum into frame blanks. Use the wire wheel to add uniform radial or linear brushing, deburr edges, then clear-coat. Back with plywood and add simple spring clips. The brushed finish elevates minimalist, modern decor.