Features

- Diamond Resin Dots for superior refinement of concretre

- Billions of diamonds to clean and shine flooring

- Reduces overall floor maintenance cost

- Double sided; one side diamond encrusted with diamond resin dots

- can be used on; floor buffers, propane burnishers, autoscrubbers

Specifications

| Color | 30 |

| Size | 20", 30 Grit |

| Unit Count | 1 |

Related Tools

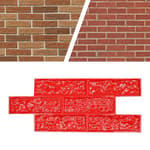

20-inch, 30-grit double-sided resin satellite pads with one side encrusted with diamond resin dots for refining and polishing concrete floors. Designed for use on floor buffers, propane burnishers, and autoscrubbers to provide abrasive action for surface preparation and light polishing.

Concrete Floor Supply Concrete DNA Resin Satellite Pads Review

Why I reached for this pad

I had two very different jobs on my calendar: prepping a garage slab for epoxy and cleaning up interior concrete after pulling tile and old carpet. For both, I wanted something faster than hand-grinding yet gentler than metal-bond diamonds. I put a 20-inch, 30‑grit resin satellite pad through its paces on a low-speed floor buffer and later on an autoscrubber to see how far a single pad could go.

This style of pad is built around resin “satellites” loaded with industrial diamonds. It’s double-sided in the sense that one face carries the diamond resin dots for cutting, while the back bonds to your driver. The concept is simple: clamp it to a 20‑inch driver, add water if you want to keep dust down, and let the embedded diamonds do the refining.

Setup and machines

I ran the pad primarily on a 175 RPM, 20‑inch swing buffer with a weighted driver and a vacuum ring for dust control. I also did a pass with an autoscrubber for wet grinding and slurry pickup in one go. You can technically mount these to a propane burnisher, but at high burnisher speeds they’re too aggressive at 30 grit; the heat and speed can shorten pad life or shed diamonds. For this grit, I recommend buffers and autoscrubbers.

A few setup tips that mattered:

- Break-in: I took a couple of light, damp passes to seat the resin dots before leaning into it. That reduced early shedding and vibration.

- Weight: Adding modest head weight improved the cut rate, but too much force slowed the motor and made the pad chatter. Find the sweet spot where the motor stays in its torque band.

- Edge work: Like any 20‑inch pad, it won’t reach right up to walls or into tight corners. I paired it with a 5-inch hand grinder.

Performance on real floors

I started with the messiest task: removing thinset ghosting and glue residue after tile and carpet removal in a kitchen and entry. With the slab dampened (not sopping), the pad chewed through adhesive smears and cleaned off leftover self-leveler ridges without gouging. It left a uniform scratch pattern appropriate for subsequent staining or coating. The finish after this 30‑grit pass wasn’t pretty—nor is it supposed to be—but it was consistent, which is what you want before stepping up in grit or laying epoxy.

On the garage job, I used it dry to profile the surface before epoxy. Dry work created a remarkable amount of dust even with a skirt and vacuum, so a respirator was mandatory. The cut was quick on the high spots, and it flattened out light trowel lines. Deep bugholes, chips, or spalls will eat any resin pad, and this one is no exception—running across a crater or raised crack edge can tear a satellite off. I marked defects and avoided them on the first pass, coming back later with patch material.

I also tested a small polish section out of curiosity: 30 grit with this pad, then switched to higher-grit resin pads to 800 and 1500. The 30‑grit cut from this pad was adequately uniform for a quality finish after progressive refinement. It’s not a substitute for metal-bond diamonds if you need to remove significant laitance or flatten heavy undulations, but for light prep and refinement, it’s a solid starting point.

Wet vs. dry

- Dry: Faster removal and easier to see the scratch pattern. You’ll generate a lot of dust; plan for extraction and PPE.

- Wet: Much cleaner air and a cooler cut. Expect “mud.” I squeegeed the slurry to a central area and used a shop vac, but the autoscrubber was the most efficient approach—grind and collect in one pass.

Wet work reduced heat and extended pad life for me, especially on denser concrete. The trade-off is the time spent managing slurry and cleanup.

Cut quality and scratch pattern

At 30 grit, the pad leaves a predictable, coarse scratch. That’s great for:

- Removing adhesive film, carpet glue, and thinset residue

- Opening up a smooth, steel-troweled surface before coatings

- Knocking down small high spots and blending self-leveler patches

It is not a finish pad. It’s a first step in a refinement sequence or a last step if you only need a profile for coatings.

Durability and consistency

Wear rate depends heavily on concrete hardness, contaminants, machine speed, and how gently you treat the pad in the first few passes. On medium-hard slabs with measured pressure, one pad handled a large residential interior before showing noticeable thinning of the resin dots. On softer or more abrasive surfaces, and where there were frequent cracks or protrusions, I burned through it much faster.

I did experience some diamond dots shedding early on one pad when I pushed the speed and ran across a chipped joint. After re-balancing the driver, slowing down, and avoiding defects until the pad was broken in, the issue largely disappeared. Still, I’d plan to have more than one pad on hand for anything over a few hundred square feet, especially if you’re tackling adhesive-heavy floors or working dry.

Practical tips from the field

- Start slow and damp for two passes to seat the pad.

- Keep the head level; tilting to dig out a spot will tear satellites.

- Overlap 50% and cross-hatch your passes for uniformity.

- Mark cracks, nail heads, and spalls so you’re not surprised mid-pass.

- If running wet, have a dedicated plan for slurry; an autoscrubber is ideal.

- Rinse the pad after use and store it flat to prevent warping.

- Avoid high-speed burnishers at this grit; the heat can glaze the resin.

Where it fits—and where it doesn’t

This 20‑inch, 30‑grit resin satellite pad shines as a bridge between cleaning and rough grinding. It’s ideal for maintenance teams and contractors doing light to medium prep, adhesive cleanup, and early-stage refinement before stepping to higher grits or applying coatings. DIYers with access to a 20‑inch buffer can absolutely get professional-looking prep with it, provided they respect the dust and take their time.

If your goal is heavy stock removal, flattening significant waves, eliminating thick epoxy, or full-depth polish on a hard troweled, very dense slab, metal-bond diamonds on a planetary grinder are still the right tool. Likewise, if your only machine is a high-speed burnisher, this 30‑grit pad isn’t a match for that RPM range.

Value and cost of ownership

The value equation here is about labor saved versus pad life. On a typical residential project, this pad can replace a lot of hand scraping and reduce the time you’d spend stepping through multiple abrasives. The double-sided construction and densely packed resin dots help, but life is highly variable. Bad floors—full of cracks, chips, or embedded grit—will shorten it. If your workflow and slab are cooperative, the pad pays for itself in speed and uniformity. If not, you’ll wish you’d budgeted for a second one.

The bottom line

The resin satellite pad did what I asked of it: it cleaned and opened concrete efficiently, handled adhesive residue without drama, and laid down a consistent scratch suitable for further refinement or coating. It produced a lot of dust when I went dry and a lot of slurry when I went wet—both manageable with the right setup. Durability was acceptable when I ran it at sensible speeds and avoided hazards, but it’s not bulletproof; push it too hard or bounce it over defects and you can shed diamonds.

Recommendation: I recommend this pad for light-to-medium concrete prep and cleanup on a 20‑inch buffer or autoscrubber, especially for coating prep, adhesive removal, and as the first step in a resin polishing sequence. Buy with the expectation that you may need more than one for larger or rougher projects, and avoid high-speed machines at this grit. If your work routinely demands heavy stock removal or you only have a propane burnisher, consider other options.

Project Ideas

Business

Mobile Concrete Polishing & Restoration Service

Offer on‑site polishing and restoration for retail, restaurants, and warehouses using the 20" 30‑grit resin satellite pads on propane burnishers or floor buffers. Market rapid turnaround (one‑day surface prep), lower long‑term maintenance costs, and the ability to restore shine without full replacement—target property managers and facility owners.

Commercial Floor Maintenance Subscription

Create a subscription program for recurring floor maintenance: scheduled buffing and light polishing using the diamond resin pads and autoscrubbers to maintain gloss and reduce stripping frequency. Package tiers (monthly/quarterly) include pad swaps, inspections, and priority scheduling—sell as a cost‑saving alternative to reactive deep restorations.

Contractor Training & Kit Sales

Sell a branded starter kit (20" 30‑grit satellite pad, safety gear, operating guide) and run short hands‑on training workshops for general contractors, terrazzo installers, and property maintenance teams. Upsell recurring pad supplies and offer certification badges that reassure customers of trained operators.

Event & Venue Floor Prep Rentals

Offer rental packages for venues and event planners: provide floor buffers/propane burnishers with preloaded 20" diamond resin pads and a certified operator for quick prep before large events. Position the service as a fast way to remove scuffs, even out surfaces, and achieve a show‑ready finish without permanent installation.

High‑End Decorative Concrete Product Line

Build a product line of polished concrete goods—countertops, tables, medallions and custom inlays—finished with the 20" 30‑grit pads to achieve exposed‑aggregate or honed aesthetics. Target architects and interior designers with portfolio photos and show how the pads produce consistent, durable finishes that reduce clients’ long‑term maintenance costs.

Creative

Exposed‑Aggregate Countertop Feature

Use the 20‑inch, 30‑grit diamond resin satellite pad on a floor buffer or hand‑guided burnisher to aggressively grind a strip or inset on a concrete countertop to expose decorative aggregate. Flip the double‑sided pad as needed for longer life, then follow with finer pads to refine and lightly polish the exposed area for a contrasting matte/gloss feature.

Terrazzo‑Style Accent Table Tops

Embed recycled glass, colored stone, or metal flakes in a concrete topping, then use the 30‑grit pad mounted on an autoscrubber or buffer to level and reveal the inclusions. The diamond resin dots accelerate material removal while producing a consistent reveal—finish with finer pads to create a glossy terrazzo look for custom tabletops.

Custom Polished Floor Medallions and Logos

Cut or cast inset medallions/logos in a concrete floor, then use the 20" diamond pad to grind the surface smooth and selectively polish the inlay to a high shine while leaving surrounding concrete honed. The pad’s aggressive 30‑grit action speeds through surface prep and the diamond resin dots deliver clean, repeatable edges for a professional decorative result.

Honed Garden Stepping Stones with Polished Tops

Create concrete stepping stones with decorative aggregate or leaf impressions. Use the pad to hone the top surface quickly and remove surface laitance; then use the opposite side or follow‑up pads to create a subtle polished highlight on design elements (e.g., initials or motifs) while keeping the rest of the stone slip‑resistant.

Mixed‑Material Sculpture Finishing

When finishing small concrete sculptures or mixed‑media pieces, use the 20‑inch pad on a small buffer or plateless grinder to rapidly refine rough surfaces and selectively polish faces for contrast. The diamond resin dots are ideal for creating crisp transitions between raw concrete texture and smooth polished areas.