Features

- Precision‑ground teeth for consistent cutting and longer edge life

- Deeper gullets to remove chips and enable faster cutting

- T‑shank design compatible with T‑shank jig saws (including Bosch and DEWALT)

Specifications

| Blade Length [In] | 4 |

| Material | High Carbon Steel |

| Tpi | 6 |

| Product Pack Quantity |

Related Tools

Related Articles

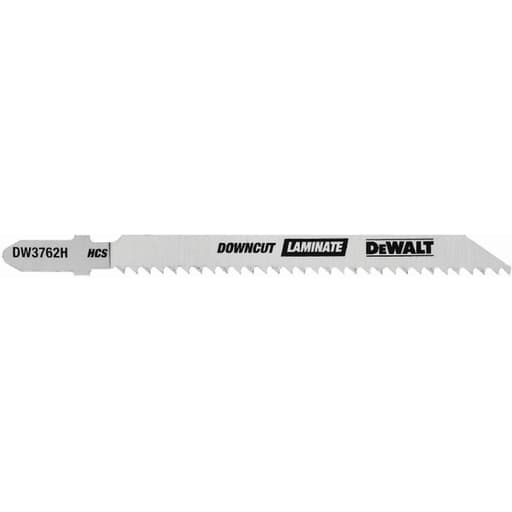

T‑shank jig saw blade intended for wood cutting. It has precision‑ground teeth and deeper gullets to aid chip removal and maintain cutting performance. Designed for use in jigsaws that accept T‑shank blades.

DeWalt 4" 6 TPI T-Shank Fast Cut Wood Cutting Jig Saw Blade Review

Why I reached for this blade

I reached for the DW3762H blade on a string of practical, rough carpentry tasks last month—cutting deck boards to length, knocking out a subfloor vent opening, and making a sink cutout in a plywood top. In all three cases I wanted speed first and foremost, with “good enough” surfaces that would be hidden, eased with a sander, or trimmed out later. A 6 TPI, 4-inch, high-carbon-steel, T‑shank blade like this one is built for exactly that brief: fast, straight-ahead wood cutting with wide chip clearance. It’s not a finishing blade, and it doesn’t pretend to be.

Design and fit

The DW3762H blade uses a T‑shank, and it locked into both my Bosch barrel‑grip and a DEWALT top‑handle jigsaw without any fuss. The shank tolerances feel right—no slop in the clamp, no unexpected pull‑out when reversing or backing out of a cut. At 4 inches, it’s a standard length for general wood work with a usable cutting depth around 2 inches before deflection and heat start becoming real factors. The high carbon steel body keeps the blade price-conscious and flexible enough to survive occasional mistakes, while the precision‑ground teeth and deeper gullets are the meaningful upgrades here. Those gullets move material out efficiently, and the ground teeth keep the cut consistent instead of chattering like stamped teeth can.

Cutting speed and chip evacuation

Speed is where this blade earns its keep. In 2x SPF, with the jigsaw’s orbital action cranked up and the speed set high, I could feed assertively without the motor bogging or the blade clogging. The deep gullets clear chips fast, which helps the teeth keep biting and stay cooler than you’d expect for a coarse blade. On pitchy pine, I saw less smear and burn than with generic coarse blades—still some pitch buildup after repeated cuts, but nothing a quick scrub with a blade cleaner couldn’t handle.

On OSB and subfloor plywood, the blade stays lively and resists that “drumming” vibration some coarse blades fall into when the chips can’t get out of the kerf. In longer rips, the aggressive tooth geometry saves time, though it’s still a jigsaw—push too hard and you’ll invite wander.

Cut quality and tear‑out

Let’s set expectations: 6 TPI is coarse. The surface it leaves in softwood is surprisingly uniform for the speed, thanks to the ground teeth, but it’s still a rough cut that’ll benefit from a quick pass with 120‑grit. On standard plywood, I saw typical top‑side tear‑out when cutting with the orbital setting engaged. Slowing the stroke rate and dialing orbital back to zero helped a bit. For visible edges in veneer plywood or melamine, this isn’t the blade to choose—switch to a fine‑tooth or down‑cut blade and use a backer or an anti‑splinter insert. For hidden edges, framing, and trim‑to‑fit tasks, it’s more than adequate.

Tracking, accuracy, and deflection

Any jigsaw blade will remind you who’s boss in thick stock, but coarse blades amplify that tendency if you feed too fast. In 1‑1/2‑inch lumber, the DW3762H blade tracked acceptably straight along a fence with light to moderate pressure. If I tried to force the pace, the kerf started to wander and the cut drifted off square on the bottom face. The fix is straightforward: let the blade set the feed rate, keep orbital moderate, and don’t lean into tight turns. For curves, it handles sweeping arcs cleanly; for tight radii, you’re better off with a narrower profile blade.

Durability and edge life

High carbon steel isn’t as hard as bi‑metal, but the precision‑ground teeth noticeably stretch the useful life here. Over a weekend of cutting SPF, OSB, and a couple of short runs in red oak, the edge stayed aggressive. I never snapped the blade—always a risk when plunging or torquing in a curve—nor did I shed any teeth. In hardwood, the bite slows sooner, and if you’re routinely cutting oak, hickory, or running into the occasional fastener, I’d point you to a bi‑metal blade instead. For softwood framing, decking, and general carpentry, the durability feels right for a consumable that prioritizes speed.

How it handled different materials

- SPF/whitewood framing: Fast, controlled, and predictable. Minimal burning, clean chip ejection.

- Pressure‑treated decking: Still quick. A bit more pitch buildup; wipe the blade periodically to keep performance up.

- OSB/subfloor: Very efficient and less chatter than expected. Tear‑out is a non-issue for this application.

- Plywood: Good for rough cutouts. Expect veneer tear‑out unless you slow down and back the cut.

- Hardwood (oak): Usable in short runs; slower and more heat‑prone. Not its sweet spot.

- PVC: Cuts quickly but leaves a ragged edge; deburr with a knife if you go this route.

Plunge cuts and start behavior

For sink and vent openings, I prefer to drill a pilot hole, but I tried a few plunge starts. The tip engages quickly and the blade enters cleanly if you begin on a low speed to avoid bouncing. There’s still some surface breakout with orbital engaged; score your layout line or use painter’s tape if the top surface matters. Once the blade is seated, you can ramp speed and finish the cut at pace.

Setup tips for best results

- Match the orbital setting to the task: high for fast softwood cuts, low/zero for plywood or cleaner edges.

- Use a fence or guide for straight cuts, and don’t overfeed in 1‑1/2‑inch stock to control bottom‑side squareness.

- For plywood, tape the cut line and cut with the good face down, or use an anti‑splinter insert.

- If you smell pitch or see dust packing in the kerf, back off the feed and clear the chips; a gummed blade loses accuracy.

- Keep a narrower, finer‑tooth blade on hand for tight curves or finish‑sensitive edges.

Compatibility and handling

No surprises here. The T‑shank design clicked into Bosch and DEWALT saws and ejected cleanly. I appreciated the lack of wobble; it helps when you’re trying to keep the shoe registered against a fence. The 4‑inch length is a good everyday pick—long enough for most framing and deck tasks, short enough to reduce flex compared to longer blades.

Where this blade makes the most sense

This is a “get it done” blade for wood: trimming deck boards, notching 2x stock, knocking out openings in sheathing, subfloor, or rough cabinetry, and general site work where speed matters more than a finish‑ready edge. It’s also a handy option for breaking down material when you don’t have a circular saw nearby. If you primarily build furniture or work in veneered sheet goods where the top surface must be immaculate, this is not your first pick—but it’s still a good blade to keep in the kit for rapid waste removal and rough shaping.

Limitations to keep in mind

- Not intended for metal or nail‑embedded wood; use a bi‑metal blade for that.

- Coarse tooth geometry means inevitable tear‑out in fragile veneers.

- In thick, hard stock, it will deflect if overfed; slow down or change blades.

The bottom line

The DW3762H blade does exactly what a 6 TPI, fast‑cut wood blade should do: it cuts quickly, clears chips well, tracks respectably with reasonable feed pressure, and holds an edge long enough to make it a reliable go‑to for rough carpentry. The precision‑ground teeth elevate it above bargain-bin coarse blades, and the T‑shank fit is solid across common jigsaws.

Recommendation: I recommend this blade for anyone who needs a fast, dependable option for wood and sheet goods in rough to semi‑rough work. It shines in framing, decking, subfloor cutouts, and general shop tasks where speed and consistency mean more than a furniture‑grade edge. If your priority is pristine tear‑out control on veneered plywood or heavy hardwood use, pair it with a finer tooth or bi‑metal blade—but keep this one nearby for the jobs that call for raw cutting speed.

Project Ideas

Business

On‑Site Custom Event Signage

Pop up at markets or weddings offering live-cut wooden names, initials, arrows, and directional signs from plywood. Use stencils/templates and the fast 6 TPI blade to produce quick turnarounds; charge per letter/size and upsell painted finishes.

DIY Project Kits with Pre‑Cut Blanks

Batch-cut parts for birdhouses, planters, coat racks, or lanterns and package them with hardware and instructions. The blade’s speed helps you scale production; sell kits online, at craft fairs, or to maker spaces and youth programs.

Rustic Wall Art Wholesale

Produce batches of silhouette wall art (states, animals, mountains) from 1/2"–3/4" plywood. Leverage the blade’s chip evacuation for continuous curves and efficient nesting of parts; wholesale to home decor boutiques and tourist shops.

Yard Game Sets

Build cornhole boards, ring-toss sets, and lawn dice. The jigsaw handles cornhole cutouts and beveled details quickly; bundle games with carrying bags and offer custom paint or logo branding for parties and corporate events.

Beginner Jigsaw Workshops

Host paid classes where attendees learn basic jigsaw techniques while making a simple project (planter, shelf, or silhouette art). The coarse 6 TPI blade keeps class pace brisk; partner with community centers or hardware stores to fill seats.

Creative

Layered Topographic Wall Art

Cut concentric, freehand contour shapes from plywood or 1x stock and stack them to mimic a topo map. The 6 TPI blade’s fast cut and chip-clearing gullets let you rough out flowing curves quickly; glue, clamp, and sand the edges for a striking, dimensional piece.

Wavy-Edge Shelves or Boards

Turn straight 1x or 2x boards into organic, live-edge-style shelves or serving boards by sketching a wave pattern and following it with the jigsaw. The precision‑ground teeth track smoothly on curves, and the coarse pitch removes material fast to shape long, fluid edges.

Animal Silhouette Yard Signs

Transfer animal outlines onto exterior plywood and cut silhouettes for garden or porch decor. The blade’s deeper gullets keep chips clear through long rips and arcs, making it easy to produce bold shapes ready for paint and staking.

Rustic Pallet Planter with Cutout Handles

Reclaim pallet slats into a planter box with arched side profiles and handholds. The fast-cut blade speeds through mixed softwoods and knots, perfect for shaping rough, rustic curves before sanding and assembly.

Puzzle-Piece Coat Rack

Cut interlocking puzzle-piece profiles from 1x lumber, then add hooks or dowel pegs. The T‑shank blade’s stable tracking helps keep tight interlocks consistent across multiple pieces that can be arranged modularly on a wall.