Features

- Hook-and-loop backing for quick attachment

- Assortment of three grits: 80, 120, 220

- Triangle shape for sanding in corners and tight areas

- Compatible with multiple manufacturers’ oscillating sanding pads (universal fit)

- Designed for material removal and repeated use

Specifications

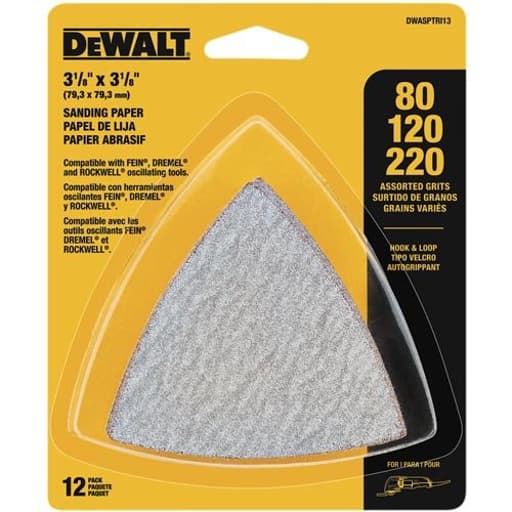

| Abrasive Material | Aluminum Oxide |

| Attachment Type | Hook-and-Loop |

| Grit Size | 80, 120, 220 |

| Length | 3-1/8 in |

| Number Of Pieces | 12 |

| Product Pack Quantity | 12 |

| Suitable For | Black and Decker, Bosch, Craftsman, DeWALT, Porter Cable, Fein, Dremel, Rockwell |

| Sku | 109236 |

| Upc | 885911281638 |

| Weight | 0.11 lbs |

| Package Width | 0.83 in |

| Package Length | 4.88 in |

| Package Height | 5.88 in |

| Model Number | DWASPTRI3 |

| Returnable | 90-Day |

Related Tools

Related Articles

Triangle hook-and-loop sanding sheets sold as a 12-piece assortment. Includes 80, 120 and 220 grits, each sheet about 3-1/8 inches in length. Sheets attach with hook-and-loop backing and are intended for use on oscillating sanding pads from major manufacturers.

DeWalt Oscillating Sanding Pad Review

What I looked for in these triangle sheets

Oscillating multi-tools aren’t my first choice for broad sanding, but they’re unbeatable for corners, louvered doors, window casings, and the awkward places where other sanders simply won’t fit. That’s where these DeWalt triangles come in. They’re aluminum-oxide sanding sheets with hook-and-loop backing, cut to a roughly 3-1/8-inch triangle and sold as a 12-piece assortment across 80, 120, and 220 grits. I ran them through a mix of jobs—leveling wood filler on pine trim, scuff-sanding painted casing, refining inside corners on cabinet carcasses, and knocking down epoxy drips—using DeWalt and Bosch pads primarily, with a quick check on an older Rockwell pad.

Build and attachment

The sheets are standard paper-backed abrasives with a consistent resin bond and a uniform grain distribution. The hook-and-loop backing lines up well on full-size delta pads, and the triangle points are cut cleanly, which matters because the tips do most of the work in tight spaces. Attachment is fast and positive when the pad is clean. This is the weak point with any oscillating pad system: once dust and resin load the hooks, everything feels half-bonded. Keeping the pad and the back of the sheet clean makes a bigger difference than the brand on the label.

A note on size: at 3-1/8 inches, these are closer to the larger delta footprints. If your pad is smaller (some older or compact multi-tools have a shorter triangle), you’ll see overhang. On my DeWalt and a Bosch OIS delta pad, the alignment was good. On an older Rockwell Sonicrafter pad, there was noticeable mismatch; the sheet extended beyond the pad by a few millimeters. That’s not a deal-breaker for light use, but it can lead to premature edge fraying and poor adhesion when you push hard.

Cutting performance by grit

80 grit: This is the workhorse for material removal. On pine trim with cured filler, 80 cut quickly without glazing, and it was easy to shape outside corners and flush off proud filler. On harder woods like oak, I had to lighten up the pressure and drop the oscillation speed to avoid heat and paper burnishing. As with any oscillating sander, you’ll get better results by letting the grit cut and resisting the urge to lean on it.

120 grit: Good for refining profiles and erasing the 80-grit scratches before primer. It’s also where I stop when I’m sanding painted surfaces for adhesion—the goal is a uniform scuff, not a polished surface. The 120 triangles did well in inside corners and along bead profiles where detail sanders sometimes skip.

220 grit: Handy for nibbing between coats and final passes on bare softwood before finishing. I wouldn’t use 220 on big surfaces with a multi-tool, but for door panels, rail-and-stile corners, or the inside of built-ins, it left a clean, even scratch pattern that disappeared under finish.

Across all grits, the aluminum oxide held up predictably. I didn’t see premature grain shedding, and the sheets wore evenly from the tip inward, which makes it easy to rotate the triangle to expose a fresh edge. That rotation is the best way to stretch life on these—spin the sheet a third of a turn every few minutes so you’re not burning up one point.

Dust, loading, and heat

Oscillating tools don’t move a lot of air compared to random orbit sanders, and dust extraction performance is largely down to your pad and vacuum setup. These sheets aren’t a mesh abrasive, so you’re more reliant on external extraction and frequent cleaning to control loading. On wood filler and paint, they will load—no way around it. My routine is simple: every minute or two, slap the sheet against my palm, vacuum the pad and backing, and get back to work. It’s mundane, but it doubles the useful life.

Heat is the enemy here. If the backing gets hot, the hooks soften and you’ll start peeling hooks off the pad or the loop off the paper. Two easy fixes: reduce pressure and drop speed. The oscillating sander rewards finesse. If I saw any sign of the backing getting glossy or the sheet slipping, I paused, cleaned both sides, and let the pad cool for 30 seconds. A thin pad saver (a sacrificial hook-and-loop interface) is cheap insurance that protects your tool’s base from damage.

Durability and the hook-and-loop interface

The abrasive layer itself held up fine. The failure mode you have to watch for is the hook-and-loop bond. If dust cakes on the hooks or resin from soft fillers transfers to the loops, the connection feels spongy and you’ll get a fly-off or the beginnings of delamination. A nylon brush or a quick blast with compressed air keeps the pad’s hooks sharp. On the sheets, a light scrape with a plastic card cleans the loops without pulling fibers.

If your work involves a lot of uncured filler or thermoplastic paint, let it cure fully and start at a lower speed with a lighter touch. Overheating soft materials is the fastest path to backing failure.

Where these triangles shine

Corners and edges: The 3-point profile gets into tight inside corners, and the crisp tips cut cleanly even on profile transitions.

Small repairs and prep: Scuffing cabinet frames before repainting, cleaning up pocket-hole plugs flush to a face frame, or tuning a mortise shoulder.

Mixed-grit workflows on small projects: Having 80, 120, and 220 in the same pack is convenient when you’re doing a few drawers or a window sash and don’t want to dig through full-size sanding sheets.

Where they’re less ideal

Mismatched pad sizes: If your oscillating pad is smaller than 3-1/8 inches, expect overhang. That overhang reduces control and accelerates edge wear. It’s workable in a pinch but not ideal.

Heavy stock removal: Oscillating sanders can do it, but they’re slower and generate more heat. A belt sander, a block plane, or a random orbit sander will be faster and easier on consumables.

High-dust, high-heat runs: Without a mesh backing or optimized extraction holes, these benefit from frequent cleaning. If you need continuous, dustless sanding on gummy coatings, a mesh abrasive system may be a better match.

Fit and compatibility

DeWalt calls these “universal,” and in practice that means they hook to most major-brand oscillating delta pads that use hook-and-loop: DeWalt, Bosch, Craftsman, Porter-Cable, Fein, Dremel, Rockwell, Black & Decker. The catch is footprint. Universal attachment doesn’t guarantee identical shape. Check your pad size; if it’s the smaller delta profile, consider a sheet that matches that footprint to avoid overhang.

On my DeWalt and Bosch setups, fit and tracking were fine. On the older Rockwell pad, the mismatch was noticeable enough that I wouldn’t choose these for daily use on that tool.

Value

As a branded 12-pack, the assortment is convenient and the abrasive quality is solid. The mix of grits suits most finishing sequences for trim and cabinetry. The only value gripe is the age-old one with assortments: you’ll burn through 80 and 120 long before 220 if you’re doing corrective work. Single-grit packs would be more efficient for heavy prep jobs. Still, as a general shop consumable, the pack makes sense and avoids overbuying any one grit.

Tips to get the most from them

Match the footprint: Measure your delta pad. If it’s smaller than 3-1/8 inches, plan on careful alignment or look for a smaller triangle.

Use a pad saver: A thin sacrificial interface preserves your tool’s hooks and reduces the cost of mistakes.

Clean often: Vacuum or brush both the pad hooks and the sheet loops. Tap the abrasive to shed dust.

Control heat: Light pressure, moderate speed, and short passes. Let the sheet cut.

Rotate the triangle: Turn the sheet periodically to get fresh corners and even wear.

Respect curing times: Let fillers and finishes cure fully before sanding to avoid gumming and backing failure.

Recommendation

I recommend these DeWalt triangles for trim carpenters, cabinet refinishers, and DIYers who need dependable corner access and a straightforward grit progression, provided your pad matches the 3-1/8-inch footprint and you’re willing to maintain the hook-and-loop interface. The aluminum oxide cuts predictably, the tips hold up well with rotation, and the assortment covers most small-project workflows. If your oscillating pad is smaller than these triangles, or if your work leans heavily on sanding soft, gummy materials without dust control, I’d look at a smaller-footprint or mesh-backed alternative. With the right pad and a light touch, these sheets are a reliable, no-drama consumable that do exactly what they’re supposed to do.

Project Ideas

Business

Cabinet Corner Refresh Service

Offer a mobile ‘corner and edge’ refinishing service for kitchen/bath cabinets. Use the triangular sanding pads to prep recessed panels, profiled corners, and tight spots quickly, then apply a bonding primer and topcoat. Price per door/drawer for quick, profitable turnarounds.

Trim & Baseboard Touch-Up

Provide on-site prep for baseboards, crown molding, and window casings. The triangle sheets reach inside corners and profiles to remove scuffs and old caulk residue. Bundle sanding, caulk, and repaint as a per-room package for landlords and Realtors.

Laser-Cut Sign Prep Service

Partner with makers who laser-cut wood signs/letters. Offer a finishing service that removes char and smooths tiny interior angles (e.g., inside ‘A’, ‘R’, ‘O’) with 80/120/220 pads. Return ready-to-finish pieces, priced by square inch or complexity.

Furniture Flip: Detail Finishing

Specialize in flipping dressers, nightstands, and cabinets where detailed corners usually get neglected. Use the triangle pads to strip/feather edges in tight joinery and ornate trim, achieving a premium finish that commands higher resale on marketplace platforms.

Workshop Class: Perfect Corners

Host paid workshops teaching surface prep and finishing in tight spaces—switching grits, avoiding swirl marks, and sealing for durability. Sell class kits with assorted grits and finishing samples, and upsell multi-packs of the triangle sheets.

Creative

Geometric Corner Art Panels

Create wall art from small geometric wood tiles (triangles, diamonds, chevrons). Use the triangle sanding sheets to quickly knock down burn marks, crisp the edges, and smooth tight inside corners on glued-up patterns. Progress through 80/120/220 grits for a professional sheen before oiling or clear-coating.

Ornate Frame Refresh

Upcycle thrifted picture and mirror frames. The triangle shape fits carved corners and filigree where larger sanders can’t reach. Use 80 grit to remove flaking finish, 120 to blend, and 220 to prep for paint or stain. Add gold leaf or color-wash for a boutique look.

Dollhouse & Miniature Detailing

Build or restore dollhouses and miniature furniture with perfectly smooth window cutouts, stair landings, and tight interior joints. The hook-and-loop sheets let you switch grits fast as you finesse tiny details before staining or micro-painting.

Shadow Box Dioramas

Craft shadow boxes with clean internal corners and layered inserts. Use the pads to smooth miters inside the box and de-fuzz delicate plywood layers. Finish at 220 grit for a silky interior that elevates the final presentation.

Custom Coasters & Trivets

Make hex, triangle, and mosaic coasters/trivets from hardwood scraps. The triangular pad slides into acute angles to remove glue squeeze-out and smooth edges. Seal with heat-resistant finish for a gift-ready set.