Features

- 🚧 Build Custom Ramps Fast: Convert standard 2"x8" planks into sturdy DIY ramps using our heavy-duty steel ramp top kit—perfect for loading ATVs, motorcycles, lawn tractors, and more.

- 🚧 Heavy-Duty Performance: Each ramp supports up to 700 lbs of distributed weight, making it ideal for lightweight utility vehicles and weekend haulers.

- 🚧 Tailgate Protection Included: Anti-slip rubber protective pads safeguard your truck bed or trailer surface during every load-in and load-out—preventing dents, damage, and sliding.

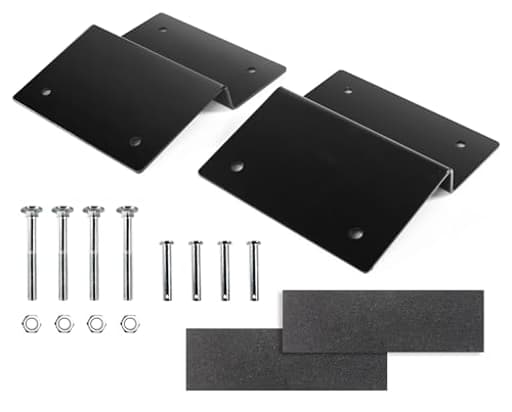

- 🚧 All-in-One Hardware Kit: Comes complete with 2 steel ramp ends, 4 bolts, 4 nuts, 4 safety pins, and 2 protective pads—no extra trips to the hardware store required.

- 🚧 Powder-Coated Steel Build: Crafted from heavy-duty powder-coated steel for exceptional strength, durability, and long-lasting rust resistance—built to handle tough jobs with confidence.

- 🚧 Versatile Ramp Solution: Compatible with 2"x8" planks of varying lengths to suit your needs—whether hauling from your garage, driveway, or off-road site. Easily fits most pickup trucks.

Specifications

| Color | Black |

| Unit Count | 5 |

Related Tools

This steel ramp top kit converts standard 2"x8" planks into ramps for loading ATVs, motorcycles, lawn tractors and similar equipment. Each ramp supports up to 700 lb of distributed weight and includes two steel ramp ends, bolts, nuts, safety pins and anti-slip rubber pads; the components are powder-coated for corrosion resistance.

MAXXHAUL 50872 Steel Ramp Top Kit - Quickly Create Your Own Ramps with 2"x8" Planks to Safely Load ATV Motorcycle and Lawn Equipment On and Off Your Vehicle Review

Why I reached for a ramp kit instead of buying full ramps

I move small equipment—mowers, a snowblower, the occasional generator—often enough to need ramps, but not so often that I want to dedicate space and cash to a big aluminum set. That’s why the MaxxHaul ramp kit appealed to me: it turns ordinary 2x8 lumber into functional loading ramps with steel ends, hardware, and protective pads. After several weekends of use across a pickup bed and a small utility trailer, I’ve come away impressed with how simple and reliable this kit is, with a few caveats worth planning around.

What’s in the box

The kit includes two powder‑coated steel ramp ends, bolts and nuts for mounting to your boards, safety pins, and rubber pads that go between the steel and your tailgate or trailer. The finish is even, welds are tidy, and the parts feel stout. Nothing flashy—just the right pieces you need to build ramps in an hour or less.

A quick note on capacity: the rating is 700 lb per ramp (distributed). In practical terms, a pair supports up to 1,400 lb if your load is shared evenly across both boards. That’s squarely in the territory for garden tractors, motorcycles, compact snowblowers, and appliances, but it’s not the kit for a side-by-side or compact tractor.

Setup: straightforward and flexible

I built my first pair with 8-foot 2x8s, kiln-dried and straight. The steel ends sit flush to the board top, and the included bolts are the right length for standard dimensional lumber. Here’s how I got up and running:

- I dry-fit the steel ends to the boards and marked hole locations.

- Pre-drilled the boards to avoid splitting, then bolted the ends on snugly.

- Added a shallow bevel to the ground end of each board with a circular saw for a smoother approach angle.

- Stuck the rubber pads to the underside of the steel ends where they meet the tailgate/trailer.

From cutting to final tightening, I spent about 40 minutes on the first pair, less on the second. If you prefer a shorter, steeper ramp for a low-deck trailer (or a longer, gentler ramp for a taller truck), you can pick board lengths accordingly. That flexibility is the kit’s biggest advantage—use what you have, or match the ramp length to the load height.

In use: stable, predictable, and confidence-inspiring

Most of my use cases have been in the 200–600 lb range, split across two ramps. With my pickup’s tailgate at roughly 32 inches, an 8-foot board gives a manageable approach angle for wheeled equipment. The rubber pads do their job; they protect the tailgate and prevent the steel from skittering under load. I haven’t had slippage issues, even on a painted trailer deck.

The ramps feel solid underfoot. There’s some natural deflection in the lumber on longer spans, as you’d expect, but no drama. Rolling a mower or generator up the boards feels calm and predictable. For lower-friction loads like a plastic sled or a dolly, the transition bump at the top is noticeable. Beveling the board’s top edge, or adding a thin aluminum threshold strip, makes that transition much smoother.

Traction on the wood is good when dry. If you expect wet, muddy, or snowy conditions, adhesive anti-slip strips or screwed-on cleats are cheap insurance. I added 1x2 cleats every foot to a second pair dedicated to winter use and found the extra bite useful for snowblower tires.

Capacity and safety: read the fine print like a pro

The published capacity assumes a smooth, controlled load shared across both ramps. A few practical notes from my testing:

- Keep the approach angle reasonable. The steeper the ramp, the higher the load on the top edge.

- Avoid abrupt starts/stops or bouncing loads—dynamic forces spike quickly.

- Center the load on each board. Don’t stray toward the outer edge of a ramp while pushing or riding.

- If you’re near the capacity, use longer boards or support the midpoint with a block to reduce deflection.

The safety pins are a nice inclusion. Depending on your setup, you can use them to lock the ramp ends to the boards and/or to a trailer lip if you have compatible holes. If your vehicle doesn’t offer a place to pin, a pair of cam straps from the ramps to tow hooks or stake pockets is a smart backup.

Build quality and durability

The steel ends are thick enough to feel reassuring, with a clean powder coat that’s shrugged off a few months of scuffs and mild weather. The hardware is basic but serviceable; I hit the bolts with a dab of anti-seize and retightened after the first use. No loosening since. I store my ramps indoors, but the kit hasn’t shown any early rust. If you’re leaving the boards outside, finish your lumber with exterior sealer; the wood will fail long before the steel if neglected.

Ergonomics and storage

Another perk of DIY ramps is storage flexibility. Two 2x8s stack flat, don’t rattle, and slide under a workbench or against the garage wall. They’re heavier than aluminum ramps of the same length, but manageable for one person to carry and position. The steel ends add a couple pounds, not a big deal. I drilled a carry hole near each board’s ground end to make them easier to grab with gloves.

Where it shines—and where it doesn’t

This kit feels purpose-built for light equipment owners who want an affordable, sturdy, and configurable solution:

- Lawn and garden gear

- Snowblowers and generators

- Motorcycles up to mid-weight

- Appliances on a hand truck

If your loads are heavy, frequent, or involve wide, low-profile tires, an aluminum arched ramp with higher capacity and integrated traction may be a better fit. Likewise, if you’re loading into a lifted truck with a tall tailgate, plan on longer boards to keep the angle sane—or consider a ramp with a gentle arch.

Small tweaks that improved my setup

- Bevel both ends of the boards. A 15–20 degree bevel at the ground end improves the approach; a light chamfer at the top smooths the transition.

- Add traction. Anti-slip tape is quick; cleats are better for snow and mud.

- Cut boards to a length matched to your bed height. I prefer 8 feet for a full-size pickup and 6 feet for a low-deck trailer.

- Label the boards left/right and store the hardware pins with a small tether to avoid losing them.

What I’d change

- An integrated way to strap the ramps to a vehicle would be welcome. The pads grip well, but physical retention is always best.

- A slightly longer top lip or a small welded threshold would soften the transition without relying on board modification.

- Optional pre-cut traction strips or a recommended pattern in the instructions would help new users set up for wet conditions.

None of these are deal-breakers, but they’re worth noting if you expect constant, all-weather use.

Value and alternatives

The ramp kit hits a sweet spot on price and capability. For the cost of the steel ends and a couple of 2x8s, you get functional ramps that rival basic aluminum sets for stability and can be tailored to your truck or trailer height. If you want the light weight and built-in traction of premium arched aluminum ramps, you’ll pay several times more. If you need only temporary access, a scrap-wood ramp will work in a pinch—but this kit makes a safer, repeatable solution with a much better interface to your vehicle.

Recommendation

I recommend the MaxxHaul ramp kit for homeowners, DIYers, and anyone who occasionally needs to load small equipment without investing in bulky, high-priced ramps. It’s sturdy, easy to set up, and adaptable to the job at hand. Respect the 700 lb per-ramp rating, choose board lengths that keep your angle reasonable, add traction for wet conditions, and you’ll have a dependable pair of ramps that earn their keep.

Project Ideas

Business

Portable Ramp Rental Service

Start a local rental business supplying portable 2x8 plank ramps for weekend projects, landscaping crews, motor clubs and event vendors. Keep sets of plank/ramp kits in multiple lengths, offer delivery and pickup, and charge per day with damage deposits. Add value by offering tie-down straps, anti-slip tape, and quick training on safe loading — high utilization with minimal inventory cost.

Custom Ramp Builds & Retrofit Kits

Offer custom-built ramps and retrofit services for customers who need pet ramps, handicap access, trailer-tailgate protectors, or bespoke motorcycle ramps. Source the ramp top kits in bulk, cut and finish premium planks, and upsell features like powder-coated rails, rubberized surfaces, branded engraving, and weather-seal treatments. Target veterinary clinics, rehab centers, motorcycle shops and landscapers for steady B2B contracts.

Pre-Packaged DIY Ramp Kits

Assemble and sell complete DIY ramp kits online that include pre-cut 2x8 planks, the steel ramp ends, hardware, anti-slip tape and step-by-step instructions or a how-to video. Market multiple lengths and weight configurations, bundle with optional accessories (straps, chocks), and create tutorial content to drive sales. Low assembly time and clear instructions let you scale through ecommerce and local pickup.

Event & Logistics Support Service

Provide on-site ramp solutions for event organizers, trade shows and filmmakers who need temporary loading ramps and stage access. Offer hourly labor with a fleet of assembled ramp kits, crew to position and secure ramps, and liability insurance. Position this as a turnkey logistics add-on — organizers pay premium rates for reliable, OSHA-aware loading support and quick teardown.

Creative

Convertible Motorcycle Service Ramp

Build a sturdy, low-profile motorcycle service ramp: attach two 2"x8" planks to the steel ramp ends, add a simple hinge and support legs so the ramp can fold into a compact service table. Add a removable wheel chock, tie-down anchor points and non-slip surface (sand/grit paint or adhesive strips). Great for home mechanics who need a portable, durable work platform that doubles as a loading ramp.

Pet & Mobility Ramp

Create a gentle, attractive ramp for pets or mobility needs by mounting the ramp ends to a long 2"x8" plank and trimming corners for safety. Add weatherproof anti-slip surfacing, side rails made from thin hardwood, and rubber feet for indoor use. The powder-coated steel ends protect surfaces and the kit’s safety pins keep the ramp secure — ideal for deck, bed or vehicle access for pets and seniors.

Garden Bridge / Raised-Planter Ramp

Turn the kit into a decorative garden bridge or planter-access ramp: use two planks joined with the steel ends as the foundation, then build low railings and integrate planter boxes along the sides. The powder-coated parts resist moisture, and anti-slip pads keep the structure stable. This gives a functional, rustic accent over small streams, rock gardens or raised beds.

Flip-Top Vendor Display & Load Ramp

Make a market-friendly folding display that converts into a loading ramp: assemble a tiered display table from planks that, with a quick removal or hinge, becomes two loading ramps using the steel ends. Use the anti-slip pads to protect countertops and add quick-release pins for fast setup/teardown. Perfect for farmers markets where you need both merchandise display and easy loading of crates/gear.