Features

- Bi-metal construction for blade flexibility and extended cutting life

- Reinforced teeth to withstand nail-embedded wood and abrasive materials

- 6° hook angle for faster cutting

- Anti-stick coating to reduce friction and sticky buildup

- Includes a hard/expandable case sized to hold up to 9 in. blades and fit power tool kit boxes

- Combination of wood- and metal-cutting blades for multiple applications

Specifications

| Number In Package | 10 |

| Saw Blade Material | Bi-metal |

| Material Cut | Multi-purpose (wood and metal) |

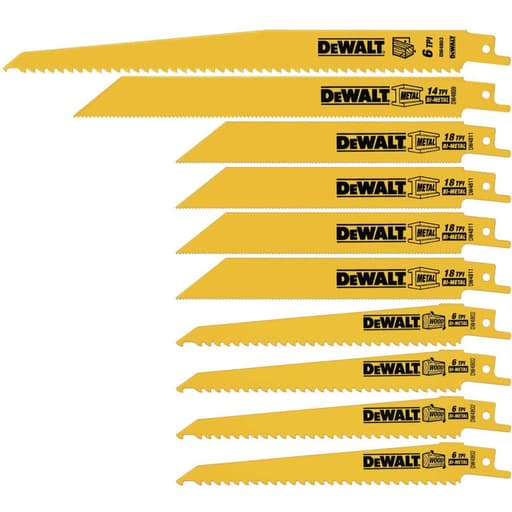

| Included Blades Breakdown | 4 × 6 in. 6 TPI (wood), 4 × 6 in. 18 TPI (metal), 1 × 8 in. 14 TPI (metal), 1 × 9 in. 6 TPI (wood) |

| Case Type | Hard / expandable (holds up to 9 in. blades) |

| Color | Yellow |

| Weight | 0.78 lb (approx.) |

| Dimensions (L×W×H) | 6.51 in × 1.38 in × 2.75 in (package/item measurements) |

| Returnable | 90-Day |

| Manufacturer | DEWALT |

| Model | DW4898 |

| Upc/Gtin | 0885911065818 |

| Store Sku / Item Id | 1005222757 |

| Prop 65 | Yes |

Related Tools

Related Articles

Ten-piece bi-metal reciprocating saw blade set for general-purpose wood and metal cutting. Blades have reinforced teeth for better durability when encountering nails and other embedded materials. A 6° hook angle is used to increase cutting speed. Blades include an anti-stick coating to reduce friction and buildup. The set is supplied with a hard/expandable case that stores blades and is designed to fit in common power tool kit boxes.

DeWalt Bi-Metal Reciprocating Saw Blade Set with Case (10-Piece) Review

Why I added this set to my kit

I tossed this 10‑piece DeWalt reciprocating saw blade set into my bag for a couple weeks of mixed jobs—stud trimming, some light demo, cutting EMT, and a small exhaust repair. I wanted a single case I could grab that would cover wood and metal without rummaging for loose singles. The DeWalt set checks those boxes on paper: bi‑metal construction, reinforced teeth to tolerate nails, a 6° hook angle for speed, and an anti‑stick coating. In practice, it’s a capable, quick‑cutting mix with a few quirks you’ll want to know about—particularly the case and how the longer blades handle if you’re heavy‑handed.

What’s in the box

The assortment is well thought out for general work:

- 4 × 6 in., 6 TPI wood blades

- 4 × 6 in., 18 TPI metal blades

- 1 × 8 in., 14 TPI metal blade

- 1 × 9 in., 6 TPI wood blade

Everything is bi‑metal and standard 1/2‑in. universal shank. The hard case is expandable and sized to hold blades up to 9 inches, which means you actually can carry the whole set in one box. It nests neatly in a typical power‑tool kit box, which is more useful than it sounds—no more crushed card sleeves.

Design notes that matter on the saw

- Bi‑metal makeup gives a good balance: flexible enough to resist snapping but stiff enough to track on a straight cut. I noticed the wood blades have a touch more body than bargain blades, which helps when you’re cutting diagonally across a stud.

- The 6° hook angle makes the wood blades feel lively. They bite quickly, especially the 6 TPI. In dimensional lumber, that translates to fast progress with less shoe pressure.

- Reinforced teeth do their job on occasional nails. You’ll still round a few teeth when you hit steel, but the edge doesn’t crater or chip out immediately.

- The anti‑stick coating does reduce pitch build‑up and heat discoloration, particularly on the metal blades. It also means the bright yellow paint will scuff, and on clean pine I did see some color transfer—nothing a pass with sandpaper couldn’t handle.

Wood and nail‑embedded wood: fast, with a couple caveats

I used the 6 in., 6 TPI blades for trimming 2x4s and cutting out a section of stud with three old bright nails in it. In straight cross‑cuts, they rip impressively fast. The hooky tooth form engages right away—almost too eagerly if you start a cut with a light touch. Keep the shoe anchored and angle into your cut for a smoother start.

In nail‑embedded sections, I felt the usual hitch as teeth met steel, but the blades kept moving. After several cuts with multiple nail strikes, the toothline showed rounding but no missing teeth. Speed dropped a bit, but the blade didn’t burn or chatter. The 9 in. wood blade is helpful for reach and flush cuts, though it’s more prone to “whipping” if you push hard with the tip unsupported. I kinked one near the last inch doing an overreach plunge into a tight cavity. That’s on me, but it’s a reminder: long recip blades are not pry bars, and they don’t love being pinched at the end of their stroke.

Metal cutting: choose the right TPI and slow the stroke

On the metal side, the 18 TPI blades were my go‑to for thin‑wall stock. I cut a handful of pieces of 3/4 in. EMT and some 1 in. angle. With a slower stroke rate and a dot of cutting wax, I got clean cuts and about 15–20 pieces of conduit before I noticed a meaningful drop in speed. The 8 in., 14 TPI blade is a good bridge for thicker wall or when you want a bit more gullet for chip evacuation. I used it on an exhaust section without drama.

Two tips that paid off:

- Dial your saw down for metal. The aggressive hook that feels “fast” in wood can feel grabby in thin sheet or tubing at full speed.

- Let the toothline do the work. If you lean on the shoe to force a cut in metal, you’ll heat the edge and dull it prematurely.

Cut quality and control

- In wood, the 6 TPI blades leave a rougher finish as expected, but they track straight if you keep the shoe planted. I didn’t see the wandering you often get with flimsier blades.

- In metal, the 18 TPI leaves a clean edge on EMT and strut with minimal burr. The anti‑stick coating helps chips shed instead of welding themselves to the blade.

Vibration was reasonable across the set; no unusual resonance that made my saw angry. If your tools have orbital action, leave it off for metal and on for fast wood cuts—these blades respond well to that change.

Durability and life

For the price range and the bi‑metal class, durability is solid but not miraculous. The wood blades survived multiple nail encounters and kept cutting, albeit with the expected slowdown. The metal blades maintained tooth integrity until they gradually dulled—no sudden toothline failures.

Bending is the bigger concern if you’re doing awkward plunge cuts or letting the blade tip pry during demolition. Shorter 6 in. blades held their shape well. The 9 in. wood blade is naturally more flexible; if you bind the last inch, it will kink and hold that memory. Technique matters here: support your work, keep the shoe engaged, and resist the urge to steer the cut by levering the blade.

If you regularly abuse blades or tear out walls for a living, a carbide‑tooth demolition blade will outlast this set by a wide margin—at a much higher price per blade. For mixed, moderate use, the life I saw is fair.

The case: smart layout, stubborn latch

I appreciate the expandable design and the fact that it truly fits 9 in. blades without mangling the tips. It slides into the bottom of my drill/driver kit box and keeps everything organized. The downside: the latch and hinge feel stiff out of the box, and the plastic is on the brittle side. Mine showed a hairline stress mark near the hinge after a drop on concrete. It still works, but I baby it now. If DeWalt beefed up the latch and used a tougher resin, this would be a home run. As it stands, it’s functional but fussy.

Value and what it’s missing

As a one‑purchase starter or replenisher, the mix hits most day‑to‑day needs: fast wood cuts, thin‑stock metal, and a mid‑TPI bridge blade. What you don’t get:

- No variable‑TPI demolition blade for mixed materials in a single cut

- No pruning‑style blade for yard work

- No carbide options for heavy demo

That’s fine if you understand what you’re buying. You can add a couple specialty blades to this kit and cover 95% of tasks most trades and DIYers face.

Tips to get the most from this set

- Match TPI to the material. 6 TPI for wood and nail‑embedded lumber, 14–18 TPI for steel and non‑ferrous metals.

- Slow the stroke rate in metal and add a touch of lube for cooler, longer‑lasting cuts.

- Keep the shoe planted; don’t steer with the blade. Long blades are for reach, not leverage.

- If you’re seeing paint transfer on finish work, scuff the blade sides lightly or mask the cut line.

- Clear chips often—especially in metal—so the gullets can keep cutting.

Who it’s for

- Remodelers, electricians, plumbers, facility techs who need a compact, reliable mix of wood and metal blades on hand

- DIYers who want a single case that covers most home projects

- Not ideal for crews doing daily heavy demolition or anyone expecting carbide‑level longevity from bi‑metal blades

Recommendation

I recommend the DeWalt set for general‑purpose use. The blades cut fast, tolerate incidental nails, and cover a sensible spread of wood and metal tasks in one compact case. You’ll get best results if you use the right TPI, keep your stroke rate appropriate for the material, and avoid prying with the long blade. The case is useful but could be tougher; treat it gently. If your work leans toward constant demo or you habitually abuse blades, look to carbide options instead. For everyday mixed cutting at a reasonable cost, this set earns a spot in the kit.

Project Ideas

Business

Mobile Light Demo & Cut-Out Service

Offer small-scale demolition and cut-out services for kitchens, baths, and decks. The reinforced bi-metal blades excel at nail-embedded wood, screws, and sheet metal. Package jobs by room or by linear foot of material removed; upsell debris haul-away.

Pallet Breakdown & Lumber Resale

Specialize in efficiently breaking down pallets without splitting boards. The 6 TPI wood blades zip through stringers and hidden nails, letting you produce clean slats for resale to DIYers and makers. Sell sorted bundles by length/species and offer delivery.

On-Site Metal/Trim Cuts for Trades

Provide rapid on-call cutting: trimming threaded rod, conduit, bolts, door jamb shims, and rusty fasteners on job sites. The 14–18 TPI metal blades give clean, controlled cuts without generating grinder sparks—ideal for finished spaces. Bill hourly plus per-cut fees.

Upcycled Industrial Furniture Microbrand

Design and sell pipe-and-wood shelving, coffee tables, and bar carts. The set covers both wood and metal components, enabling fast prototyping and small-batch builds. Market through local markets and Instagram; offer custom dimensions for premium pricing.

Storm/Damage Cleanup Crew

Launch a rapid-response service to clear downed fences, trim broken studs, and cut twisted sheet metal after storms. The anti-stick coating helps in wet/dirty conditions, and reinforced teeth handle unexpected nails. Offer flat-rate emergency calls plus disposal.

Creative

Pallet Wood Accent Wall/Headboard

Reclaim pallet boards into a rustic accent wall or headboard. Use the 6 TPI wood blades to quickly slice through nail-embedded slats without worrying about hidden fasteners, then trim ends square. The anti-stick coating helps when cutting resinous softwoods. Finish with stain and a matte clear coat.

Industrial Pipe + Wood Shelving

Build floating shelves with black iron pipe or EMT conduit supports. Cut pipe to length using the 14–18 TPI metal blades for burr-free edges, and rip/trim shelf stock with the 6 TPI wood blades. The bi-metal teeth handle occasional screws or nails in reclaimed lumber, giving an authentic industrial look.

Upcycled Steel Drum Side Table

Turn a 55-gallon steel drum into two modern side tables. Use the 14 TPI or 18 TPI blades to cut the barrel cleanly, then add a round plywood or live-edge top cut with the 6 TPI blade. The anti-stick coating reduces chatter and heat, and reinforced teeth help when hitting spot welds or ribs.

Garden Trellis/Planter Combo

Create a sturdy trellis from rebar or scrap flat stock and attach it to a cedar planter box. Cut metal uprights and crossbars with the metal blades and notch/fit cedar with the wood blades. The set’s versatility lets you mix materials for a durable, weather-ready garden feature.

Scrap Metal Silhouette Art

Cut animal or geometric silhouettes from thin steel sheet or old signage using the 18 TPI blade for tighter curves. Mount pieces on reclaimed wood backers trimmed with the 6 TPI blade. Minimal finishing needed—raw mill scale and saw marks add character.