Features

- Zirconia alumina abrasive for extended life and material removal

- Resin bond

- High grain concentration for consistent grinding action

- Wheel design to improve durability

- Fiberglass reinforcement sheets for added strength and safety

Specifications

| Arbor Size | 5/8"-11 |

| Disc Diameter | 9 in |

| Disc Thickness | 1/8 in |

| Number Of Pieces | 10 |

| Product Pack Quantity | 10 |

| Includes | (1) Grinding Wheel (per listed unit) or sold in 10-piece pack |

| Reinforcement | 3 full sheets of fiberglass |

| Warranty | 30 Day Money Back Guarantee |

Related Tools

Related Articles

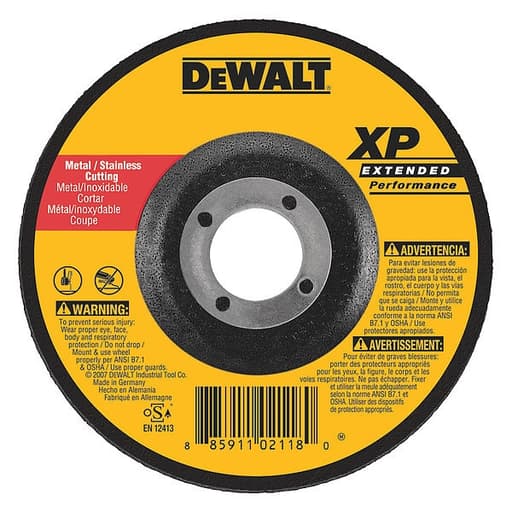

Type 27 metal grinding wheel made with zirconia alumina abrasive and a resin bond. It is intended for grinding metal, offering a high grain concentration for material removal and smoother running. The wheel is reinforced with fiberglass layers for added strength and safety.

DeWalt 9" x 1/4" x 5/8"-11 XP Metal Grinding Wheel (Type 27) Review

Why I reached for this wheel

I grabbed the 9-inch DeWalt wheel for a weekend of heavy weld cleanup and bevel prep on a mix of A36 plate and 304 stainless. I wanted a coarse, no-nonsense grinding wheel I could lean on without babysitting it, and this one promised exactly that: a Type 27, 24-grit zirconia alumina disc with a resin bond, fiberglass reinforcement, and a 5/8-11 hub—tailor-made for a 9-inch grinder. Over several hours of grinding, I paid attention to cut rate, heat, edge durability, and overall feel. It never became the star of the show, and I mean that as a compliment.

Build and specs that matter

- Wheel type: Type 27 (depressed center)

- Size: 9 in diameter x 1/4 in thick

- Grit: 24 (coarse)

- Abrasive: zirconia alumina in a resin bond

- Arbor: 5/8-11

- Max speed: 6600 rpm

- Wheel hardness: R

- Reinforcement: fiberglass

- Intended materials: stainless steel and ferrous metals

- Pack quantity: 10

On paper, that’s a classic formula for heavy stock removal. The 24-grit zirconia cuts aggressively and keeps sharpening as it fractures. The “R” hardness is a practical middle ground: not so hard that it glazes on lower-power grinders, not so soft that it erodes on corners. Fiberglass sheets add torsional strength and impact resistance—reassuring when you’re leaning into a 9-inch grinder.

Setup and compatibility

The wheel seated true on a standard 5/8-11 spindle and ran concentric with no shim fuss. The depressed center clears most flanges and guards, and the balance felt good out of the wrapper—no unusual vibration or chatter on startup. With a maximum operating speed of 6600 rpm, it pairs with most 9-inch grinders. Don’t put it on a higher-rpm 7-inch machine; stay within the printed limits and keep the proper guard installed.

Cutting performance on mild steel

I started by knocking down 3/8-inch fillet welds on A36. At a 20–30 degree angle, the wheel moved material with authority. The cut is classic coarse-zirconia: a gritty, steady bite rather than a slick “skate.” I could keep pressure consistent without the wheel stalling or glazing, and removal remained even across the face.

- Stock removal: strong for a 24-grit Type 27, with fast cap knockdown and bevel prep

- Heat: predictable; it throws a healthy spark stream but didn’t overheat the work when I kept the angle and pressure sensible

- Wheel face: wore evenly, no premature ridging or cupping

The 1/4-inch thickness stabilizes the wheel under load and helps avoid “digging in.” It’s not for plunge cuts (use a cutoff wheel for that), but for grinding and blending, the footprint keeps things controlled.

Stainless behavior and finish

On 304, zirconia alumina is a safer bet than basic aluminum oxide, and that showed here. It cut cooler, didn’t smear, and resisted loading when I kept the wheel moving. I wouldn’t call the finish pretty—24 grit leaves deep scratch marks—but it’s exactly what you want for weld removal or bevel prep before a flap disc. If you’re working on code-critical stainless where contamination is a concern, verify your shop requirements; in my experience this wheel didn’t introduce obvious staining, but some specs call for explicitly labeled Fe/S/Cl-free wheels.

Wear, life, and edge durability

Wheel life felt solid for the class. Zirconia’s self-sharpening trait showed up as the face fractured into fresh cutting points rather than glazing. I didn’t see chunking on corners or random grit shelling. The wheel tolerated edge work on gussets and brackets without losing geometry, and it maintained a stable face after multiple heat cycles. You’ll still consume it faster if you bear down at steep angles, but it rewarded a slightly open angle and steady pressure with both speed and longevity.

Across a long day, one wheel carried me through:

- Full removal of several linear feet of 3/8-inch weld cap

- Bevel prep on 1/4-inch plate

- A quick cleanup pass on a mower blade (because real life)

Expect to follow with a 40-60 grit flap disc if you need a finish that won’t telegraph through paint.

Control, comfort, and mess

A 9-inch setup is never delicate, but this wheel ran smoothly. Balance felt right, and the resin bond didn’t “grab” or bounce against the work. At a sensible angle, I got consistent contact with minimal chatter. Spark volume is high (as you’d expect at this grit), so guard placement and PPE matter. Dust was typical for a coarse wheel; if you’re indoors, local extraction pays off.

Technique tips for best results

- Angle: 15–25 degrees for flat surfacing; up to 30 degrees for faster removal on heavy welds

- Pressure: firm and steady; let the zirconia do the cutting—pushing beyond the bite just builds heat and wastes wheel

- Movement: keep the wheel traveling to avoid heat spots and grooves

- Dressing: not usually necessary; if you glaze, back off on pressure and open the angle slightly

- Materials: stick to stainless and ferrous metals; skip aluminum and other gummy nonferrous materials (use dedicated nonferrous wheels)

Durability and safety

The fiberglass reinforcement adds confidence when you’re pushing hard at the edge of a fillet or working a tight spot. I did the usual ring test before mounting; the wheel sounded right and stayed quiet at speed. As always: respect the max rpm, keep the guard on, and don’t side-load beyond what a Type 27 is meant to handle. If you’re new to 9-inch grinders, remember they have enough torque to surprise you—two hands, proper stance.

Where it shines—and where it doesn’t

Strong fits:

- Heavy weld removal on structural steel

- Beveling and edge prep before welding

- Stainless grinding where standard aluminum oxide struggles

- Shop environments where a 10-pack makes sense and consistency matters

Less ideal:

- Fine finishing—24 grit is too coarse to stop at

- Light-duty or delicate work—use a smaller wheel or a flap disc

- Nonferrous metals—expect loading and smearing

- Grinders that exceed 6600 rpm—don’t mismatch

Value and consistency

Buying in a 10-pack makes sense if you run grinders regularly. The wheels I used were consistent in balance, face behavior, and wear pattern. No out-of-box wobble or soft spots. If you need absolute maximum life and the coolest cut on stainless, premium ceramic wheels exist—but at a higher price. This DeWalt wheel lands in a sweet spot: faster and cooler than basic aluminum oxide, with solid durability, at a cost that doesn’t sting when you burn through a couple in a long shift.

The bottom line

The DeWalt wheel does what a good 9-inch, 24-grit Type 27 should: it bites hard, keeps its face, and stays predictable on both mild steel and stainless. The zirconia alumina abrasive is the right choice here, balancing speed and life without the price premium of top-tier ceramics. You’ll still want a flap disc to finish, and you’ll want to keep it off nonferrous metals, but for heavy grinding on ferrous materials it’s a trustworthy, no-drama option.

Recommendation: I recommend this wheel for fabricators, welders, and maintenance techs who need a reliable, coarse grinding wheel for stainless and carbon steel. It’s a strong performer with sensible safety margins, good life, and consistent quality—especially worthwhile if you’ll use the 10-pack over time. If your work is mostly finishing, nonferrous, or on smaller grinders, choose a different wheel type; otherwise, this one earns a spot on the cart.

Project Ideas

Business

Weld-Prep and Cleanup Service

Offer mobile beveling, mill-scale removal, and weld cleanup for contractors and hobbyists. The zirconia alumina wheel enables fast, consistent edge prep and post-weld blending to reduce client fabrication time.

Trailer and Equipment Refurbishing

Provide rust removal, weld repair cleanup, and surface prep on trailers, racks, and farm equipment. Package tiers: basic derust and blend, structural repair finishing, and paint-ready prep.

Custom Metal Furniture Line

Design and sell industrial-style furniture—benches, shelves, and tables—highlighting clean, blended welds and signature grind textures. Market limited runs with consistent finishes achieved via the wheel’s high grain concentration.

Architectural Metal Finishing for Builders

Partner with local fabricators to deliver on-site finishing of stair stringers, handrails, and gates. Specialize in flush welds, radius edges, and uniform surface textures as a premium add-on service.

Metal Art Commissions and Signage

Offer custom steel logos, nameplates, and art panels with layered grind patterns that shimmer under clear coat. Upsell LED backlighting and rust-inhibiting finishes for indoor/outdoor installations.

Creative

Layered Grind-Pattern Wall Art

Create abstract wall panels from sheet steel and use the wheel to carve sweeping grind patterns that catch light at different angles. Overlay multiple plates with contrasting ground textures and spot-weld them into a dimensional mosaic.

Industrial Coffee Table Base

Fabricate a steel base from square tubing, then use the grinding wheel to flush welds, blend corners, and add uniform brushed textures. Finish with a clear coat and pair with a reclaimed wood or glass top.

Garden Sculptures from Scrap

Transform scrap metal into flora or abstract outdoor sculptures. The wheel’s fast stock removal helps shape curves, smooth rough edges, and add intentional surface striations for visual contrast.

Custom BBQ Pit and Smoker Finishing

Build a steel smoker or fire pit and use the wheel to remove mill scale, clean up welds, and radius sharp corners. Add decorative grind lines and a heat-resistant finish for a professional look.

Modern Metal Planter Set

Weld geometric planters from 11–14 ga sheet, then grind all seams flush for a seamless look. Introduce intentional chamfers and a uniform surface grain before sealing for outdoor durability.