Features

- More Cuts. Fewer Wheels.™

- 50% Longer Life*. Replace wheels less often with Temper Point™ grains that are tougher and razor sharp for more cuts. Better adhesion between the coated grains and resin creates a longer lasting cutting edge that wears slowly

- Extremely versatile: Efficiently cut a wide range of metals including carbon steel, stainless and nickel-based alloys

- Aggressive cutting action: Make fast cuts with a thin wheel design and high-grain concentration

- Durable by design™: Built with two sheets of fiberglass for wheel strength. Designed to reduce wheel breakage

Specifications

| Arbor Size [In] | 7/8 |

| Bonded Abrasives Application | Cutting |

| Bore Size [In] | 7/8 |

| Disc Diameter [In] | 4-1/2 |

| Disc Thickness [In] | 0.045 |

| Disc Type | Depressed Centre |

| Max. Speed [Rpm] | 13300 |

| Number Of Pieces | 1 |

| Product Diameter [In] | 4-1/2 |

| Rpm | 13300 |

Related Tools

Related Articles

Replace wheels less often with Temper Point™ grains that are built tougher to maintain razor sharpness for up to 50% longer life*. Get a longer lasting cutting edge that resists wear-and-tear with enhanced adhesion between the coated grains and resin. Efficiently cut a wide range of metals including carbon steel, stainless, and nickel-based alloys with the wheels" thin designs and high-grain concentration. These wheels are exceptionally durable and are built with 2 sheets of fiberglass for optimized strength to help to reduce breakage.

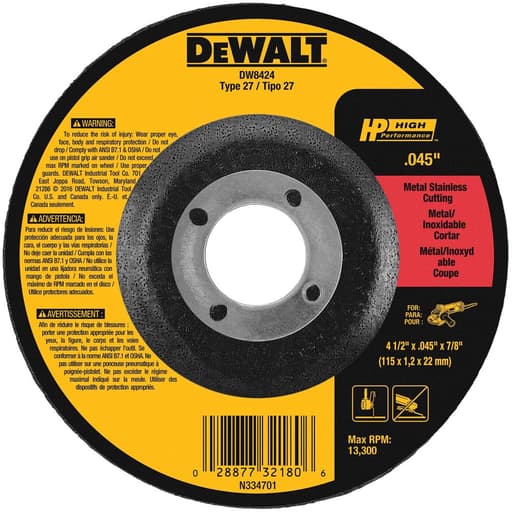

DeWalt High Performance Cutting Wheels Review

When you're tackling a project that involves cutting through tough metals, the right cutting wheel can make all the difference. Recently, I had the opportunity to work with DeWalt's High Performance Cutting Wheels (model DW8424 Z), and I must say, they left a lasting impression. These cutting wheels are designed to handle a variety of metals, including carbon steel, stainless steel, and nickel-based alloys. From my experience, they live up to the hype in terms of durability and efficiency.

The first thing that struck me about these cutting wheels is their construction. DeWalt has clearly put a lot of thought into making these wheels last longer. The enhanced grain adhesion is a standout feature, ensuring the wheel maintains its sharpness for extended periods. This means fewer replacements and more consistent performance throughout the life of the wheel. For anyone who has spent time swapping out worn-out wheels mid-project, this is a significant advantage.

One of the key features of these cutting wheels is their thin design. At just 0.045 inches thick, they allow for fast, precise cuts. This thin profile is particularly useful when you need to make quick, clean cuts without generating excessive heat. Heat can be a significant issue when cutting through metals, as it can warp the material and reduce the lifespan of the cutting wheel. With these DeWalt wheels, I found that heat buildup was minimal, even during prolonged use.

Another aspect of these cutting wheels that I appreciated is their versatility. They are suitable for a wide range of metals, making them a valuable addition to any workshop. Whether I was working with carbon steel or stainless steel, the wheels performed consistently well. This versatility means you don't need to keep multiple types of cutting wheels on hand, simplifying your toolkit and saving you money in the long run.

Durability is always a concern when it comes to cutting wheels, and DeWalt has addressed this with reinforced construction. These wheels are reinforced with two sheets of fiberglass, which significantly reduces the risk of breakage. During my time using them, I never experienced any issues with the wheels snapping or breaking, even when applying considerable pressure. This added durability gives you the confidence to tackle even the most challenging cuts without worrying about the wheel failing.

The specifications of these cutting wheels are also worth noting. They have an arbor size and bore size of 7/8 inches, a disc diameter of 4-1/2 inches, and a maximum speed of 13,300 RPM. These specs make them compatible with a wide range of grinders and cutting tools, adding to their versatility. The high maximum speed ensures that you can make quick, efficient cuts, further enhancing the overall performance of the wheels.

In terms of performance, these cutting wheels exceeded my expectations. One of the most challenging tasks I undertook was cutting through a thick piece of Hastelloy X, a nickel-based alloy known for its toughness. By keeping the pressure light and making shorter cuts, I was able to cut through the material with relative ease. The wheel maintained its sharpness throughout, and I didn't experience any significant wear until well into the project. This kind of performance is a testament to the quality and durability of DeWalt's design.

For more everyday tasks, such as cutting through an old clothesline pole, these wheels also shined. The process was straightforward and much easier than using a hacksaw. The cutting wheel made quick work of the pole, and I was able to complete the task in a fraction of the time it would have taken with a manual saw. This ease of use is another reason why these cutting wheels are a valuable addition to any toolkit.

While the performance and durability of these cutting wheels are impressive, it's also worth mentioning their affordability. Given the quality and longevity of the wheels, they offer excellent value for money. You might pay a little more upfront compared to some cheaper alternatives, but the extended lifespan and consistent performance mean you'll save money in the long run by not having to replace them as frequently.

One minor drawback I noticed is that while the wheels are excellent for bulk metal cutting, they may not be the best choice for precision cuts. If your project requires extremely precise, detailed cuts, you might need to look for a more specialized tool. However, for general-purpose cutting and most workshop tasks, these wheels are more than adequate.

In conclusion, I highly recommend DeWalt's High Performance Cutting Wheels. Their durability, versatility, and efficiency make them a standout choice for anyone who regularly works with metal. The enhanced grain adhesion, thin design, and reinforced construction ensure that they can handle a variety of tasks with ease. While they might not be the best option for precision cutting, their overall performance and value for money make them an excellent addition to any toolkit. Whether you're a professional or a DIY enthusiast, these cutting wheels are sure to meet your needs and exceed your expectations.

Project Ideas

Business

Custom Metal Fabrication Service

Start a business offering custom metal fabrication services for clients needing bespoke metal parts or products. Utilize the cutting wheels for precise and efficient cuts, ensuring client satisfaction.

Metal Art Workshops

Host workshops where participants can learn to create metal art using high-performance cutting wheels. This not only generates revenue but also builds a community around metalworking.

Online Metal Art Store

Create an online store to sell handmade metal art and decor items. The precision and durability of the cutting wheels will help produce high-quality products that can be marketed online.

Custom Automotive Parts

Offer custom automotive parts fabrication, specializing in unique or hard-to-find metal components. The cutting wheels' efficiency will ensure timely delivery and high-quality parts.

Metal Prototyping Service

Provide a prototyping service for inventors and engineers needing precise metal parts for their prototypes. The cutting wheels can help produce accurate and reliable components, essential for prototype testing.

Creative

Metal Sculpture Art

Use the cutting wheels to create intricate metal sculptures. The precision and durability of the wheels allow for detailed work on various metal types, opening up possibilities for unique art pieces.

Custom Metal Furniture

Design and build custom metal furniture such as tables, chairs, and shelving units. The cutting wheels make it easy to cut different metals to precise measurements, ensuring high-quality, durable pieces.

Decorative Garden Structures

Craft decorative garden structures like trellises, arches, and planters. The versatility of the cutting wheels helps in creating both functional and aesthetically pleasing garden items.

Metal Jewelry Making

Create unique metal jewelry pieces such as earrings, necklaces, and bracelets. The thin design of the cutting wheels allows for fine, detailed cuts essential for jewelry making.

DIY Home Decor

Design and produce custom home decor items like wall art, nameplates, and candle holders. The cutting wheels' ability to handle various metals ensures durability and a high-quality finish.