Features

- Stabilizes blade to reduce bending during cutting

- Guides blade for straight, consistent cuts

- Designed for production/continuous cutting

- Twin-blade counter‑reciprocating action to reduce vibration and noise

- Available in multiple lengths to suit material thicknesses

- Easy to install

Specifications

| Length | 8 in (200 mm) |

| Compatible With | GSG300 foam cutter (as specified by supplier) |

| Maximum Material Thickness | Designed for use with material less than 8 in thick |

| Pack Quantity | 1 |

| Dimensions | 24 x 9 x 9 cm (supplier listing) |

| Weight | 0.6 kg (supplier listing) |

Related Tools

Related Articles

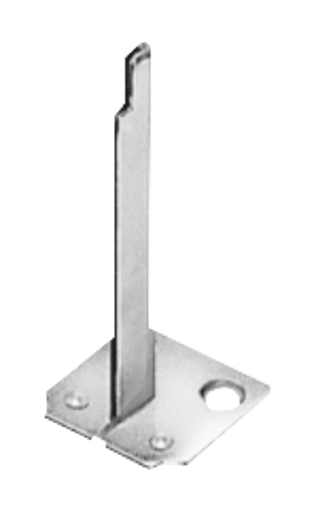

Blade guide for foam rubber cutters that stabilizes the blade to produce straight, consistent cuts. Intended for production or continuous cutting of materials such as foam rubber, flexible plastic foams and many types of carpeting. Available in different lengths to match workpiece thickness.

Bosch 8 in Foam Rubber Cutter Guide Review

Why I reached for this guide

Cutting foam straight and clean is harder than it looks. Even with a counter‑reciprocating foam cutter, long runs in upholstery foam or carpet underlay can make the blades wander. I brought the Bosch 8-inch guide into my workflow to tame that blade deflection and get repeatable, square cuts on production runs. After several weeks of daily use on furniture cushions, case inserts, and carpet templating, it has earned a permanent spot on my cart.

What it is and how it fits

This is a dedicated 8-inch blade guide designed to pair with Bosch’s foam cutters, including the GSG 300. The guide stabilizes the twin blades along their length, acting like a fence right where it matters: at the cut. At 200 mm in length, it’s meant for material up to, but not exceeding, 8 inches thick. Bosch offers other lengths; I chose 8 inches to cover most upholstery and packaging foam I see, with the option to swap to a shorter guide for thinner stock.

Physically, the guide is compact and sturdy. The listed weight of about 0.6 kg gives it a solid, non-flimsy feel, and its footprint (roughly 24 x 9 x 9 cm packaged) makes it easy to tuck into a drawer when it’s not attached. Installation was straightforward; it attaches securely to the cutter with no drama, and once locked down, there’s no rattle or misalignment. I had it mounted and ready in a few minutes on the first go.

Compatibility note: I ran it on the GSG 300 as specified by the supplier. If you’re pairing it with anything else, verify fit before buying—guides are not universal across brands or even across all models within a brand.

Performance in the cut

Straightness and squareness: The biggest win is how well it keeps cuts plumb through the full 8-inch depth. With the guide on, I see minimal “hourglass” effect or edge taper. Crosscuts on high-resilience foam blocks came off the bench ready for upholstery with almost no additional truing.

Blade stability: Foam cutters are already good at reducing vibration thanks to their counter‑reciprocating action, but long blades can still deflect. The guide supports the blade pair close to the cut path, limiting flex. On flexible polyurethane foam and cross‑linked polyethylene (XLPE), it noticeably reduced chatter and kept the kerf uniform.

Consistency on production runs: For repetitive, straight cuts—think cushion blanks, large packaging nests, or carpet strips—the guide turns the setup into a repeatable process. Once I dialed in my fence or layout lines, each subsequent cut matched the first.

Noise and feel: The guide doesn’t change the motor sound, but it does damp some of the blade “singing” in tall foam. Feed pressure felt more linear; I didn’t have to nurse the cut as much to prevent the tip from drifting.

Curves and templates: This is not the attachment for tight curves. It’s perfect for straight lines and gentle radii. If I need to follow a tight template, I remove the guide to regain maneuverability.

Materials I tested

- Upholstery foam (2–7 inches, various densities): Clean, square edges with no melting or polishing of the faces. The guide shines here.

- Memory foam (3–6 inches): The support helps avoid compression at the cut line. I got better dimensional accuracy because the blade didn’t push the foam away as much.

- Cross‑linked polyethylene foam (up to 4 inches): Slightly tougher feed, still straight and clean.

- Carpet with jute and synthetic backings: Great for ripping long, straight strips. The guide helps keep the blade running parallel to a straightedge without “walking” when the backing fights you.

Setup and technique tips

- Match the guide length to the material: For dead‑square faces on thicker foam, the guide height should cover the full material thickness. If your block is taller than 8 inches, use a longer guide or plan on flipping and making a second pass.

- Mark a clear cut line: With the guide installed, your sight line is a touch more constrained. Bold layout lines or a clamped straightedge make precise work easier.

- Let the blades do the work: Resist the urge to shove. A steady feed produces the best surface finish and truest edges.

- Support the offcut: Especially with tall foam, let the offcut fall away without pinching the blade. I keep a helper or a stand on the outfeed side.

- Keep the blades sharp and aligned: The guide can’t fix dull or misaligned knives. If you see fuzzy edges or increased heat, it’s time for maintenance.

Build quality and durability

The guide feels stout with no perceptible flex once mounted. The surfaces that contact the blade are smooth and haven’t shown wear ridges so far. After repeated installs and removals, the attachment points still hold tight. Nothing about it reads as disposable; it’s an accessory meant for regular, continuous use in a shop setting.

What it does not do

- It won’t add capacity: The 8-inch designation is a limit, not a suggestion. For blocks over 8 inches, choose a longer guide or plan a different approach.

- It’s not for intricate curves: The added stabilization naturally resists tight turns. For sculpted foam or complex templates, run without the guide.

- It doesn’t replace a fence: While the guide keeps the cut vertical, you still need a straightedge, fence, or accurate layout to keep the cut on track horizontally.

Who benefits most

- Upholstery and cushion shops cutting tall foam regularly.

- Packaging and casework where square edges and repeatability matter.

- Carpet installers needing straight, parallel strips with a clean edge.

- Anyone running a Bosch GSG 300 (or verified compatible model) for daily or weekly production.

If you make only occasional, thin foam cuts, the benefit is still there, but a shorter guide might be a better fit—and you may not need a guide at all for quick, rough work.

Pros

- Excellent stabilization for straight, square cuts up to 8 inches.

- Noticeably reduces blade deflection and chatter in tall foam.

- Quick, simple installation and a secure mount.

- Durable construction suited to continuous use.

- Available in multiple lengths to suit different jobs.

Cons

- Limits maneuverability on tight curves.

- Adds a small amount of visual bulk near the cut line.

- Compatibility is specific—confirm your cutter model.

Buying and sizing advice

Pick the guide length based on your most common maximum foam thickness, not your average. If you occasionally cut 7–8 inch blocks, this 8-inch version is the right choice. If your work tops out at 4 inches, a shorter guide may handle better around slight curves while still providing full-depth support. And before purchasing, double-check that your cutter matches the supported models—this guide is specified for the Bosch GSG 300.

The bottom line

For me, the 8-inch guide transformed tall-foam cuts from a careful, hands-on coaching exercise into a controlled, repeatable process. It keeps the blades honest, the edges square, and the work predictable. While it’s not the right tool for tight curves, its benefits on straight and gentle arcs are immediate and obvious.

Recommendation: I recommend this guide to anyone regularly cutting foam up to 8 inches thick with a compatible Bosch cutter. It saves time, reduces rework, and improves cut quality in a way that’s easy to feel and see. If your work is primarily thin foam or intricate curves, you can skip it or choose a shorter version—but for production straight cuts, this is a worthwhile, dependable accessory.

Project Ideas

Business

Custom Acoustic Panel Shop

Offer made-to-order acoustic panels and wall kits. Use the guide for fast, repeatable cuts across batches and multiple thicknesses, enabling standard sizes plus custom widths without investing in large industrial equipment.

Pet Bed & Cushion Inserts

Produce foam inserts for pet beds, kennels, and window perches. The guide ensures uniform sizing for covers and lets you offer tiered firmnesses and subscription replacements for pet owners and shelters.

Stair Runner & Carpet Trim Service

Provide mobile precision cutting for stair runners, thresholds, and room transitions. On-site straight cuts reduce waste and fitting time, improving seams and alignment for installers and homeowners.

Event & Retail Foam Signage

Make large-format foam letters, numbers, and logo backers for pop-ups, weddings, and window displays. Straight, consistent cuts speed production of long edges and frames, with upsells for paint, fabric wrap, or LED accents.

Foam Cutting Service Bureau

Contract-cut foam and carpet components for local makers, upholstery shops, theater departments, and prop houses. Price by cut length or batch, leveraging the guide for production runs with tight tolerances.

Creative

Cosplay Armor & Prop Cores

Use the guide to rip EVA and upholstery foam into perfectly straight strips and panels for armor bases, sword cores, and shield laminations. Straight, consistent seams make edge-gluing cleaner, reduce filler work, and speed up assembly for mirrored parts.

Geometric Acoustic Wall Art

Batch-cut foam tiles (hex, chevron, and stripe patterns made from straight segments) to create decorative acoustic panels. The guide keeps cuts true across long pieces so patterns align tightly, improving both aesthetics and sound absorption.

Modular Kids’ Soft Blocks

Produce dimensionally accurate foam cubes, beams, and wedges from flexible foam sheets. The stabilized blade prevents wandering, so blocks stack neatly and can be wrapped in removable fabric sleeves for washable, safe play sets.

Custom Upholstery Cushions

Cut precise blanks for chair seats, window seats, and bench cushions from foam rubber. Straight edges make it easier to fit into sewn covers, and consistent thickness along long cuts helps achieve a professional, wrinkle-free finish.

Carpet Inlay Rugs

Create graphic rugs by cutting carpet into uniform strips and shapes for inlay mosaics and borders. The guide keeps cuts straight on nap and backing, allowing tight-fitting inlays with clean seams and repeatable pattern pieces.