Features

- Tapered core for increased strength and reduced flute breakage when drilling deep holes

- Two‑stage flute with variable helix pattern for more efficient debris removal

- Two carbide cutting edges to produce clean, round holes

- Wear mark indicator to help verify hole diameter

- Manufacturer replacement under a No Break Guarantee while the wear mark is visible (exclusions apply)

- Carbide tip design to increase carbide surface contact and extend bit life

Specifications

| Number Of Pieces | 1 |

| Overall Length (In) | 6 |

| Product Diameter (In) | 1/2 |

| Product Length (In) | 6 |

| Working Length (In) | 4 |

| Product Pack Quantity | 1 |

| Number Of Flutes | 4 |

| Shank Type | SDS+ |

| Usable Length (In) | 4 |

Related Tools

Related Articles

SDS Plus 2‑cutter carbide drill bit for masonry drilling. It has a tapered core to reduce the risk of flute breakage during deep drilling, a two‑stage flute with a variable helix to move debris away from the cutting area, and two carbide cutting edges to produce clean, round holes suitable for anchor installation. Made in Germany. The manufacturer provides a replacement under a No Break Guarantee while the wear mark is still visible (exclusions may apply).

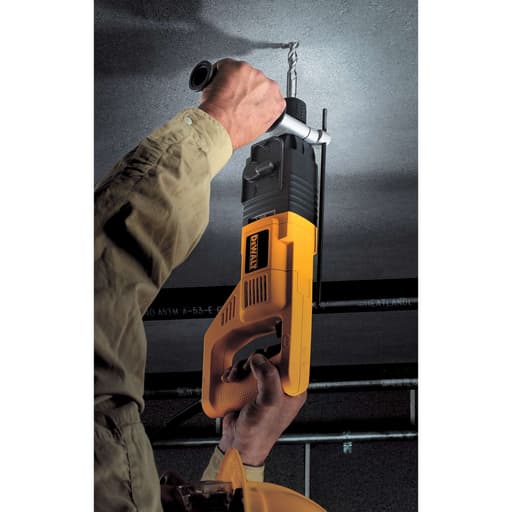

DeWalt 1/2" x 6" 2‑cutter SDS Plus carbide drill bit Review

Why I keep a 1/2-inch SDS Plus bit in the kit

I reach for a 1/2-inch masonry bit more often than I expect—wedge anchors, sleeve anchors, drop-ins—it’s a workhorse size on commercial and residential jobs alike. After several projects with the DeWalt 1/2-in SDS Plus bit, I’ve formed a clear picture of where it shines and where a different style might be a better choice.

Design and build

This bit uses a two-cutter carbide head paired with a two-stage flute that transitions to a steeper, variable helix. On the drill, it looks fairly conventional, but the details matter. The head geometry puts a decent amount of carbide on the nose without getting bulky, and the core is tapered to resist twisting or snapping under load—particularly important as the hole deepens and chips drag through the flutes. The SDS Plus shank fit my hammers without any slop and locked in positively.

The working length is 4 inches, with a 6-inch overall length. That depth covers most anchor embedments and through-holes in standard block and brick. For deep embedments or thick structural elements, you’ll want a longer version, but this length hits a useful sweet spot for day-to-day work.

There’s also a wear mark laser-etched in the flute. It’s not a gimmick. That line gives a visual cue for diameter loss, which can be the difference between a snug anchor and one that spins. Once you strike past it, you should retire the bit for code-critical holes.

In concrete, block, and brick

In cured, 3,500–4,000 PSI slab, the bit tracks well and starts cleanly without skating. With a mid-size SDS Plus rotary hammer set to hammer drill, I got predictable bite with no chatter. The two-cutter head tends to dig in a touch faster than multi-cutter designs in medium concrete, and I noticed that here as well—it cuts assertively without needing to push hard.

CMU block and brick are almost effortless. The variable helix pulls fines out quickly, which keeps the cutting lips engaged instead of grinding dust. For tap-through holes in brick veneer or CMU webs, it maintains a round path without blowing out the exit, provided you let the hammer do the work and don’t pry at the end.

Speed, accuracy, and hole quality

Drilling speed is solid for a two-cutter design. It’s not the absolute fastest I’ve used in very soft block, but in mixed aggregate or slightly harder concrete, the balance of speed and control feels right. The bit stays on line with minimal wander after the first 1/4 inch.

Hole roundness and diameter are good enough for anchors. Drop-in anchors that call for a 1/2-inch hole fit with a reassuringly snug tolerance, and 1/2-inch wedge anchors seated without needing to wallow the hole. The wear mark did its job as the bit aged—when I began to approach that line after a run of holes in tough material, I could see slightly looser fits and retired the bit for critical anchors. That’s exactly how the feature is meant to be used.

If you hit rebar, a two-cutter can skate or chip the carbide—this isn’t a rebar-cutting bit. I could scrape across light wire without serious drama, but on true bar, plan to relocate the hole or swap to a rebar-rated four-cutter head.

Debris evacuation and heat

The two-stage flute with variable helix is more than marketing. As the hole deepens, fines rise out of the bore consistently, and I didn’t run into the common 1/2-inch problem of packed dust causing the bit to bind with every pump of the hammer. That said, on deep holes at the edge of its 4-inch working length, I still follow best practice: withdraw the bit a couple of times to clear chips, and use a blower or vacuum with a brush to clean the hole before placing anchors. You can feel the bit run cooler when you manage chips properly.

Durability and wear

The carbide tip holds its edge well. After multiple anchor layouts in cured concrete and some runs through CMU, the cutting lips were still crisp and the shank showed no fretting from the tool interface. I didn’t encounter flute fracture or twisting, which aligns with the tapered core’s intent. Abuse will still kill any bit—leaning hard on the tool or trying to pry the hole round—but under normal hammer drilling, this one resists the common failure modes.

The made-in-Germany stamp will matter to some users. In my experience, it often correlates with consistent brazing on the carbide and good straightness out of the package. This sample ran true with no perceptible wobble.

Compatibility and setup

As an SDS Plus shank, it fits the common 7/8-inch and 1-inch class rotary hammers most crews carry. I ran it primarily on a mid-power SDS Plus hammer and occasionally on a compact model; both were up to the task. Keep the tool in hammer-drill mode, use the auxiliary handle for control, and let the hammering do the cutting—too much axial force just increases heat and wear.

For dust-sensitive environments or silica compliance, the bit plays nicely with on-tool extraction boots or hollow-core vac systems. While it’s not a hollow bit, the flute design doesn’t fight the vacuum; coupled with a proper brush, it leaves holes ready for adhesive or mechanical anchors.

Where it excels

- Everyday anchor holes in concrete, CMU, and brick

- Through-holes in masonry for pipe clips, straps, and brackets

- Situations where diameter accuracy matters (thanks to the wear mark)

- Users who want a bit that stays straight and clears chips well without babysitting

What could be better

- Not ideal for drilling through rebar; if you routinely encounter steel, a four-cutter head is more forgiving

- The 4-inch working length covers most needs, but structural applications may require a longer version, so plan your kit accordingly

- Two-cutter heads can leave slightly rougher hole walls in very hard aggregate compared to premium multi-cutter designs, though I didn’t find it problematic for anchors

Tips for best results

- Start square and let the hammer establish the path; avoid side load, especially in brick

- Pulse the bit out of deep holes to help the flutes clear; don’t “pump” the tool aggressively in the hole

- Vacuum, brush, vacuum for anchor holes—chip evacuation from the hole matters as much as chip evacuation from the bit

- Keep an eye on the wear mark; once it disappears, retire the bit for code-critical anchors

- If you suspect rebar, scan beforehand or be ready with a rebar-cutting bit

Warranty and value

DeWalt backs this bit with a no-break style guarantee while the wear mark is still visible, with the usual exclusions. That aligns with how I’d use the bit anyway: keep it in service for precision work until the wear mark is gone, then demote it to non-critical holes. It’s a sensible policy that reflects real-world usage.

Final recommendation

I recommend the DeWalt 1/2-in SDS Plus bit for general masonry drilling and anchor installation. It drills at a confident pace, produces anchor-ready holes, clears debris effectively, and holds up under typical jobsite abuse. The wear mark is a practical touch for quality control, and the tapered core inspires confidence when you’re pushing toward the end of its working length. If your work regularly involves drilling through rebar or demands the smoothest possible hole walls in very hard concrete, consider a four-cutter alternative for those tasks. For everything else in the 1/2-inch range, this bit earns a spot in the case.

Project Ideas

Business

Precision Anchor Drilling & Installation

Offer a service specializing in wedge, sleeve, and epoxy anchor installation in concrete, brick, and block for homeowners and contractors. Market the accuracy advantage using the wear mark to verify hole size, plus faster cleanout from the variable‑helix flutes. Package pricing by hole count and anchor type; add dust‑control and epoxy upgrades.

Retail/Restaurant Masonry Mounting

Provide turnkey drilling and mounting for shelves, menu boards, signs, TV displays, and queue stanchions on masonry surfaces. Clean, round holes improve anchor reliability in high‑traffic environments, and the compact 6" length is ideal for tight interiors. Offer after‑hours installs to reduce downtime.

Home Gym and Safety Upgrades

Install pull‑up bars, squat rack base anchors, handrails, and grab bars into masonry. Emphasize correct hole sizing and anchor seating for safety‑critical hardware. Offer inspection and re‑torque visits as a recurring revenue add‑on.

Greenwall/Trellis Mounting for Landscapers

Partner with landscapers to drill and set anchor points for trellises, vine wires, and planter brackets on brick and concrete. Efficient debris removal speeds multi‑hole runs, helping you price competitively per drop point.

Seasonal Facade Anchor Points

Install removable stainless anchor points in brick or concrete for holiday lights, banners, and event signage. Use the wear mark to document hole diameter in a simple service report, then sell seasonal install/removal contracts for recurring income.

Creative

Masonry Peg Grid Wall

Drill a precise grid of 1/2" holes in a garage or basement concrete wall and set 1/2" drop‑in anchors. Thread in studs to support interchangeable wooden pegs, shelves, and hooks. The two‑cutter tip makes clean, round holes for reliable anchor fit, and the wear mark helps verify diameter across the grid.

Rebar Trellis and Planter System

Create a modern trellis by drilling 1/2" holes in a patio slab or concrete planters and epoxying short lengths of 1/2" rebar as verticals. Add crossbars and string for climbing plants. The variable‑helix flute clears dust efficiently when drilling multiple holes outdoors.

Basalt Bubbling Fountain Stone

Turn a small basalt or river stone into a tabletop fountain by drilling a 1/2" pass‑through for tubing and a base hole for a hidden pin. The tapered core adds strength if you need deeper passes, and the carbide edges help maintain a straight, round channel for leak‑free tubing.

Industrial Pipe Shelving on Brick

Mount black‑pipe flanges to a brick wall for an industrial shelf system. Use the bit to drill anchor holes with consistent diameter (verified by the wear mark) so sleeve or wedge anchors hold tight under load.

Concrete‑Mounted Fitness Rig

Install a pull‑up bar or punching‑bag bracket into a masonry wall using wedge or epoxy anchors. The two‑cutter design produces round, on‑size holes that seat anchors properly, and the robust core resists breakage when drilling several deep holes.