Features

- Metal gear housing

- Heat-treated, helical-cut steel gears

- Depth-sensitive "set-and-forget" nosepiece for consistent fastener depth

- Two-finger trigger

- Rubber grip for improved hold

- Variable speed with reversible motor

- Lightweight design for reduced fatigue

- Suitable for drywall to wood and light-gauge metal studs (up to 20 gauge)

Specifications

| Amps [A] | 6.3 |

| No Load Speed [Rpm] | 4000 |

| Max. Torque [Ft Lbs] | 81 |

| Max. Torque [In Lbs] | 81 |

| Weight | 4.2 lb |

| Cord Length | 8 ft |

| Dimensions (H × W × D) | 3.19 in × 12.25 in × 10.19 in |

| Included | Screwgun (tool only) |

| Warranty | 3 Year Limited Warranty; 1 Year Free Service; 90 Days Satisfaction Guaranteed |

| Applications | Fastens drywall to wood and light-gauge metal studs; steel stud framing up to 20 gauge |

Related Tools

Related Articles

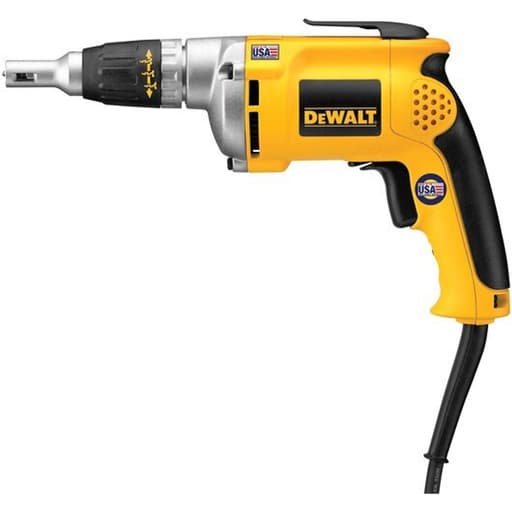

Corded variable-speed drywall screwgun with a top speed of 4,000 RPM. It uses a metal gear housing and heat-treated, helical-cut steel gears for durability. The tool has a depth-sensitive nosepiece for setting consistent fastener depth, a two-finger trigger and rubber grip for user control, and a reversible motor. Intended for fastening drywall to wood and light-gauge metal studs (up to 20 gauge).

DeWalt 4,000 rpm VSR Drywall Screwgun Review

Why I reached for a drywall screwgun

I spend a lot of time hanging board in renovations and small commercial spaces, and while a drill/driver can get the job done, it’s not the right tool for consistent, flush (or slightly dimpled) screw heads without tearing paper. A dedicated screwgun earns its keep with repeatability and speed. That’s why I put the DW272 to work over several rooms and a couple of ceilings—enough time to see whether its features translate into real gains on site.

Build and ergonomics

The DW272 feels purpose-built. The metal gear housing and helical-cut, heat-treated gears give it a solid, tight feel with minimal slop at the nose. There’s no rattle in the nosepiece, and the bit stays true when you press into the board. At 4.2 pounds, it’s lighter than most cordless options I’ve used, which makes a difference overhead. The body is compact enough to tuck between studs, and the balance hits right where your index finger rests on the two-finger trigger.

The rubber overmold isn’t overly soft, but it offers enough grip when your hands are dusty. The 8-foot cord is serviceable—you’ll still need an extension in most rooms, but it’s long enough to avoid constantly tugging on your shoulder. I would have liked a rotating belt hook or a clip for hanging off a pocket; that’s not included, so plan your staging accordingly.

Fit and finish are what I expect from DeWalt’s corded pro line: clean molding, a square nosepiece that adjusts positively, and a robust forward/reverse switch that never felt vague. After longer runs, the gear case warms slightly, but not to the point of discomfort.

Speed and control

This screwgun’s motor spins up to a listed 4,000 RPM, and the variable-speed trigger makes that range usable. Drywall screws don’t need torque as much as they need consistent speed and a predictable cut into the gypsum and paper, and here the DW272 is easy to modulate. I routinely start screws at a slower speed, then bury them quickly once the thread bites. The trigger is smooth, and the motor responds without lurching.

A reversible motor isn’t critical for driving drywall, but it’s extremely handy for backing out proud or mislocated screws without chewing up the paper. The gearbox doesn’t freewheel wildly in reverse; backing out feels controlled.

Noise and vibration are both reasonable. The helical-cut gears run quieter than some straight-cut setups I’ve used, and there’s very little buzz in the handle. Over a long day, that matters.

Depth setting: the make-or-break feature

Depth control is the reason to own a screwgun, and the DW272’s “set-and-forget” nosepiece does what it promises—once you dial it in. Expect a short learning curve if you haven’t used this style of nose before. Here’s what worked for me:

- Start conservative. On scrap, set the nose to leave screws just proud, then creep deeper in small increments.

- Hold firm pressure and keep the gun perpendicular to the surface. The clutch action relies on consistent pressure to disengage cleanly.

- Let the speed do the work. Don’t feather the trigger through the final millimeter; drive with intent and let the nose stop the screw.

Once set, I was able to move quickly with repeatable results: clean dimples around the head without tearing paper. On ceilings, where angles change your leverage, I bumped the depth one click shallower to avoid overdriving. The nosepiece stayed locked, even after frequent forward/reverse cycling and a few bumps against studs.

Bit changes are quick. The nose cone pulls off, revealing a standard 1/4-inch hex holder. I kept a couple of fresh Phillips bits on hand, and the nose design guided the screw well enough that I rarely chased starts, even one-handed.

Performance on wood and light-gauge metal

The DW272 is designed for drywall to wood and light-gauge steel up to 20 gauge, and it stays comfortably in that lane. On wood studs, the motor has no trouble keeping up with fast, continuous driving. In 20-gauge studs, thread engagement is crisp, and the high top speed helps prevent cam-out—especially useful with fine-thread screws.

Push it beyond 20 gauge and the limitations show. It will still drive into heavier steel with self-drillers, but speed and depth consistency suffer, and it’s not what this tool is intended to do. For heavy-gauge framing or roofing screws, reach for a dedicated TEK screwgun or an impact with suitable control.

Day-to-day usability

A few practical notes from the field:

- The two-finger trigger is comfortable with gloves, and the pull is light enough that finger fatigue wasn’t an issue.

- The cord does occasionally snag on staging or the board stack. That’s the trade-off for a lighter, always-ready tool with no batteries to rotate. I managed it with a cord over-the-shoulder and a floor runner to keep it from catching.

- Dust management is better than average. Gypsum dust didn’t clog the nosepiece or build up excessively in the vents, but I still blast it out with compressed air at the end of the day.

- The tool-only package means you’ll supply your own bits and accessories. That’s typical in this category, but worth noting if you’re kitting up from scratch.

Durability and service

After several rooms and a couple of days of continuous ceiling work, I saw no drift in depth setting, no looseness in the nose, and no change in motor tone. The metal gear housing inspires confidence, and the switchgear feels like it will last. DeWalt’s warranty—three-year limited, one-year free service, and 90-day satisfaction—is solid backing for a corded tool at this price point. I haven’t needed service, but it’s reassuring if this will be a jobsite staple.

Where it fits in the lineup

Corded drywall screwguns aren’t glamorous, but they remain the most economical way to get consistent, professional results without the weight and battery management of cordless. The DW272 is a straightforward, reliable option if:

- You mostly work within reach of power.

- You value lighter weight for overhead work.

- You don’t need a collated feed system.

If your workflow is all about speed across big open areas, a collated screwgun will outpace any single-feed model. And if you’re constantly on lifts or navigating around obstacles, the cord is the main compromise here. For remodelers and small crews who hang and then immediately tape in the same space, the trade-offs favor the DW272.

Tips for best results

- Use quality bits and swap them at the first sign of cam-out; depth systems can’t compensate for a worn tip.

- Set depth on scrap from the same lot of board you’re hanging; paper thickness can vary slightly.

- In corners and tight framing, keep the nose flat to avoid false disengagement; if needed, slow down a touch.

- For ceilings, pre-mark joist lines and keep a consistent stance—your body alignment affects how the nose engages.

Final recommendation

I recommend the DW272 for anyone who wants a dependable, corded drywall screwgun that prioritizes consistency, speed, and manageable weight. It excels at its core job: driving drywall screws to a repeatable depth in wood and 20-gauge steel, all day, without fuss. The depth-sensitive nosepiece is accurate once set, the 4,000 RPM motor gives you the pace you need, and the build quality suggests a long service life. The main reasons to look elsewhere are workflow-driven: if you need cordless mobility or a collated system for maximum throughput, this isn’t the right tool. But for mixed remodel work, small commercial projects, and crews that value simplicity and reliability, the DW272 is a smart, proven choice.

Project Ideas

Business

Drywall Patch & Pop Repair Service

Offer fast, clean repairs for nail pops, screw pops, and small holes. Use the depth-sensitive screwgun to resecure loose drywall to studs with perfectly set fasteners, then finish and paint. Market as a same-day, fixed-price service for homeowners and property managers.

Small Job Drywall Installations

Specialize in quick-turn partitions, closets, soffits, and basement finishes. The 4,000 RPM screwgun boosts productivity on repetitive runs and ensures uniform screw depth, reducing callbacks for flashing or ridging.

Soundproofing Upgrades

Provide home office and studio isolation packages: resilient channel or hat track, acoustic sealant, and double-layer drywall. The tool’s consistent depth protects channels from shorting and maintains performance specs clients can hear.

Steel Stud TI Partitions

Target commercial tenant improvements with light-gauge steel stud framing (up to 20 ga) and drywall sheathing. Promote clean, consistent fastener setting for better finish quality and faster schedules in offices, clinics, and retail build-outs.

Crew Training & QC Audits

Offer on-site training for crews on optimal screw patterns and depth, leveraging the screwgun’s set-and-forget nosepiece. Provide punch-list audits with photo documentation, reducing finishing defects and warranty claims for builders and GCs.

Creative

Curved Drywall Feature Wall

Create a flowing accent wall by attaching kerfed or pre-scored drywall to flexible ribs or segmented light-gauge metal studs. The depth-sensitive nosepiece lets you set consistent dimples for clean finishing without tearing the paper, and the 4,000 RPM speed keeps the long screw runs fast and uniform.

LED Cove Lighting Soffit

Build an L-shaped drywall soffit around a room perimeter to conceal LED strip lighting. Frame it with light-gauge steel studs (≤20 ga) and skin with drywall. The screwgun’s lightweight body reduces fatigue overhead, while the set-and-forget nosepiece prevents overdriving at corners for crisp edges.

3D Topographic Drywall Mural

Cut layered ‘contour’ shapes from drywall and fasten them to a plywood backer that’s anchored to studs to form a sculptural wall map or abstract relief. The depth-stop ensures each screw sets just right for easy mudding and sanding to blend layers seamlessly.

Home Theater Acoustic Wall

Upgrade a media room with resilient channel and double-layer drywall for improved sound isolation. The variable speed and reversible motor speed up fastening to wood studs or 20-ga channel, and the consistent screw depth reduces telegraphing under paint.

Recessed Niche Gallery

Frame shallow niches between studs using light-gauge metal and finish with drywall for a modern display wall. The screwgun’s precise depth control makes tight inside corners and small panels easier to finish with minimal joint buildup.