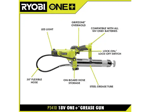

Features

- Mini grease gun with needle nozzle

- Easily lubricates air tools and other flush type mini grease type fittings

- Pack bottom side with grease, then re-install base cap and push up against the inside plate with a screwdriver or other tool to feed grease up to nozzle and pressurize

- Apply additional pressure to inside plate occasionally as needed

- Holds 3 ounces of lubricant, can be operated with one hand

- Heavy duty, lightweight and easy to handle

- Weight 1 lbs

Specifications

| Unit Count | 1 |

Related Tools

Related Articles

Mini grease gun with a needle nozzle for lubricating air tools and flush-type mini grease fittings. It holds 3 ounces of lubricant, weighs 1 lb, and can be operated one-handed; grease is loaded from the bottom and fed to the nozzle by pressing the internal plate to build pressure.

Astro Pneumatic Tool 101 Mini Grease Gun Review

I keep a small, metal grease gun within arm’s reach on my bench, and over the past several months this mini grease gun has earned a permanent spot there. It’s a compact, needle‑nozzle gun meant for air tools and flush-type fittings, but it’s just as at home on bikes, small machines, and chainsaw bars. The appeal is simple: precise delivery, minimal footprint, and enough capacity to matter without turning into a messy commitment.

Build and ergonomics

The body is all metal and feels sturdier than its size suggests. At roughly a pound and holding about three ounces of grease, it’s balanced well enough to operate one‑handed. The pump action has a short, consistent stroke that makes it easy to meter tiny amounts, which is the whole point of a needle‑tip gun. The nozzle is fine enough to get into sprocket holes, flush ports on air tools, and bearings where you’d rather place instead of smear.

There’s nothing flashy here—no windows, no quick‑load cartridges, no fancy couplers. It’s a classic, simple mechanism with a threaded head and a bottom cap. The simplicity is a virtue for durability, but it also defines how you need to use and maintain it.

Filling and priming: what works best

This style is packed from the bottom, and it relies on an internal plate (a follower) to push grease toward the pump. Here’s the routine that has worked cleanly for me:

- Pop off the bottom cap and push the internal plate up near the top with a screwdriver or dowel. Leave a little space.

- Pack in grease from the bottom. I use a butter knife or a narrow spatula; tapping the body sharply against my palm helps the grease settle so you can add more.

- Thread the bottom cap back on firmly.

- Press the internal plate upward through the hole in the cap with a screwdriver to pressurize the reservoir and help purge air.

- Pump the handle with the nozzle aimed back into your grease tub until you get a steady bead.

Once primed, it stays primed. Every so often, as the grease level drops, I give the plate another push to maintain pressure. It’s not difficult, just different from spring‑loaded cartridge guns.

A practical note: the joint where the body threads into the head can weep a trace of grease during aggressive priming. It’s not a functional problem, but if you want a bone‑dry joint, a thin oil‑resistant gasket or a wrap or two of PTFE tape on the threads seals it up nicely. After that tweak, mine has stayed clean around the seam.

Performance and control

The pump delivers grease in a narrow, predictable bead. That precision is what I value most. On bike hubs and linkage bearings, I can add just enough without creating a cleanup project. On chainsaw bars with a sprocket hole, the needle reaches in and fills the cavity with far less waste than those disposable push tubes. On air tools, the needle hits flush ports without fighting a coupler.

Pressure is surprisingly good for a compact manual gun; it moves light to medium greases reliably. The stroke resists just enough to give feedback when a cavity is full. You can feather the output to prevent overpacking seals.

Grease choice matters

While it will move NLGI #2 grease, the experience is better with softer greases—NLGI 0 or 00 flows beautifully and makes the pump action feel effortless. For cold shops or tight needle work, a lighter grade reduces hand force and improves control. For general bike work, I’ve run a ceramic/PTFE blend without issue; for chainsaw sprockets, 00 has been excellent. If you insist on #2 chassis grease, keep expectations reasonable—short, firm strokes and more deliberate priming help.

On the bench and in the field

This gun shines as a bench tool. The small footprint means it lives neatly beside my hex keys and cable cutters, and because it’s one‑handable, I can hold a part with the other hand while applying grease exactly where it’s needed. It’s tough enough to toss in a tool bag, too. I keep one loaded with light grease for delicate mechanisms and another with a general‑purpose EP formula. At the price point, dedicating one per grease type is a clean, practical approach that avoids cross‑contamination.

Maintenance, mess, and small quirks

- Priming: Don’t skip pressurizing the plate from the bottom before the first use. It purges air pockets and makes the first stroke productive.

- Sealing: If you notice a little weeping at the head threads during priming, add a thin gasket or PTFE tape. It’s a simple fix that tightens up the assembly feel.

- Nozzle care: The needle is robust enough for routine work, but I avoid prying with it. A protective cap or a bit of heat‑shrink tubing over the tip keeps dust out between uses.

- Cleanliness: Wipe the nozzle after each session and store the gun upright. Because the follower relies on your occasional push to maintain pressure, upright storage helps prevent slow seepage.

None of these are dealbreakers. They’re just the realities of a minimalist, refillable design. The trade‑off is owning a small tool that lasts, costs little to keep fed, and doesn’t lock you into proprietary cartridges.

Where this mini grease gun makes the most sense

- Bikes: Bearing seats, freehub internals, suspension linkage hardware, and seatpost assembly paste placement. The fine control reduces over‑greasing.

- Chainsaws: Sprocket‑tip bearings via the needle, bar studs, and clutch bearings.

- Air and pneumatic tools: Flush fittings take the needle perfectly; a quick hit keeps rotors and hammers happy.

- Small machinery: Linear bearings, slides, hinges, and cams with tight access.

If you primarily service vehicles with zerk fittings and need high volume and quick coupler attachment, a full‑size lever or pistol‑grip gun is better. But even in an automotive shop, having a needle‑tip gun on hand prevents the “too much grease in the wrong place” problem on delicate assemblies.

Durability and value

The metal construction and simple mechanism inspire confidence. There’s not much to wear out beyond seals and the follower plate, and both are well supported by the grease itself. The value proposition gets better the more you use it: three ounces lasts a long time for precision tasks, and buying grease by the tub is more economical than running through specialty squeeze tubes. If you service multiple tool types, a couple of these loaded with different greases are still cheaper than most single premium cartridge guns.

Limitations to consider

- Manual pressurizing: Pushing the internal plate is part of ownership. If you want a set‑and‑forget spring follower and standard cartridges, this isn’t it.

- No quick‑change tips: It’s a needle‑nozzle tool by design. You can swap needles if you’ve got alternatives, but don’t expect a zerk coupler out of the box.

- Thick grease in the cold: It can move #2, but at shop‑fridge temperatures you’ll work harder. Store warmer or use a softer grade for winter use.

None of these are unexpected for this category; they’re just worth noting so you match the tool to the job.

Recommendation

I recommend this mini grease gun for anyone who needs precise, clean, small‑volume lubrication with a needle tip. It’s compact, durable, and easy to control, with just enough capacity to be useful without becoming messy. The bottom‑pack design takes a minute to learn, and you may want to seal the head threads if you’re particular about cleanliness during priming, but once set up it’s a reliable, low‑cost workhorse. For bikes, chainsaws, air tools, and small machinery, it’s the right tool to keep grease exactly where it belongs—and not all over your bench.

Project Ideas

Business

On‑Site Pneumatic Tool Lubrication Service

Offer scheduled maintenance visits to contractors, automotive shops, and body shops to lubricate air tools and flush‑type fittings. The mini grease gun’s needle nozzle and one‑handed operation let you service hard‑to‑reach fittings quickly, reducing downtime for busy shops. Charge per tool or on a subscription basis.

Pre‑Filled Specialty Cartridge Kits

Create and sell pre‑measured, pre‑loaded 3‑ounce cartridges of specialty greases, wax blends, leather balm, or hobby putties compatible with the mini grease gun. Market niche kits to bike shops, modelers, leatherworkers, and small‑engine repair shops — offer refill subscriptions and spare needle kits as add‑ons.

Maker Workshops & Class Kits

Run hands‑on classes teaching precision application techniques for mixed media artists, modelers, and leatherworkers, using the mini grease gun as the key tool. Sell bundled starter kits (tool + needle nozzles + sample mediums) at the end of classes so students can continue projects at home.

Micro‑Repair & Restoration Service

Provide a niche service focused on small, high‑value repairs — antique furniture scratch fills, instrument hardware lubrication, or precision wax repairs for collectibles. Use the grease gun for clean, controlled deposits of waxes and fillers; advertise quick turnarounds and minimal invasiveness for small restorations.

Retail Maintenance Packs for Hobby Shops

Develop and supply compact maintenance packs (mini grease gun + compatible lubricant samples + spare needles) targeted at hobby stores, RC shops, and sewing machine dealers. Position the pack as the ‘portable maintenance solution’ for enthusiasts who want on‑the‑spot lubrication and small repairs.

Creative

Model Putty & Filler Dispenser

Load epoxy putty, hobby filler, or heavy body modeling clay into the mini grease gun to lay down tiny beads and seams on scale models, miniatures, or props. The needle nozzle and one‑handed operation let you place putty precisely in panel lines, gaps, and joints before smoothing — great for modelers who need repeatable, small deposits without sticky fingers.

Texture & Heavy‑Body Paint Applicator

Use the gun to apply heavy gel medium, modeling paste, or stiff acrylic texture directly onto canvas for raised lines, ridges, and 3D effects. The needle nozzle creates controlled cords or dots for abstract work and mixed‑media pieces. Because the unit builds pressure, you can get consistent flow of thick mediums without hand‑squeezing tubes.

Leather Edge & Stitch Conditioning Tool

Fill with leather balm, wax‑based edge finish, or tacky dressing (non‑runny formulas) to apply precise amounts to belt edges, stitched seams, or tight creases. The needle reaches narrow areas and the one‑hand operation allows you to work seams while feeding an item with the other hand — useful for small leather goods repair and finishing.

Wood & Candle Wax Repair Pen

Mix softened beeswax or colored furniture wax to a pasteable consistency and load into the grease gun to fill small scratches, gouges, or cracks in wood and wax items. The needle tip lets you deposit repair wax only where needed, then level and buff for an invisible repair — good for quick touch‑ups on frames, trim, and vintage pieces.

Stamping/Embossing Paste Tool

Use the gun to dispense embossing paste or texture medium into stencils and stamps for cardmaking and paper crafts. The precise flow prevents squeegeeing excess and makes it easier to fill tiny stencil details consistently for batches of cards or stationery.