Features

- High grain concentration for improved cutting performance

- 5/64 in (≈2 mm) thin wheel profile for faster, low‑burr cuts

- Designed for use with high‑power cutoff saws that accept 7/8 in arbors and 9 in wheels

Specifications

| Arbor Size | 7/8 in |

| Bore Size | 7/8 in (22.23 mm) |

| Disc Diameter | 9 in (230 mm) |

| Disc Thickness | 5/64 in (2 mm) |

| Disc Type | Flat |

| Material | Ceramic bonded abrasive (for metal) |

| Application | Cutting — medium‑heavy wall pipe, general weld, structural steel |

| Operating Speed | 6,600 RPM (listed by some retailers) |

| Pack Quantity | 1 |

| Number Of Pieces | 1 |

| Product Weight | 0.18 kg (0.9 lb) |

| Product Dimensions | Diameter 9.02 in (229 mm); Height 0.91 in (23 mm) |

| Segmented Or Continuous | Continuous |

| Has Ce Mark | No |

| Warranty | No limited warranty (product indicated as not eligible) |

Related Tools

Related Articles

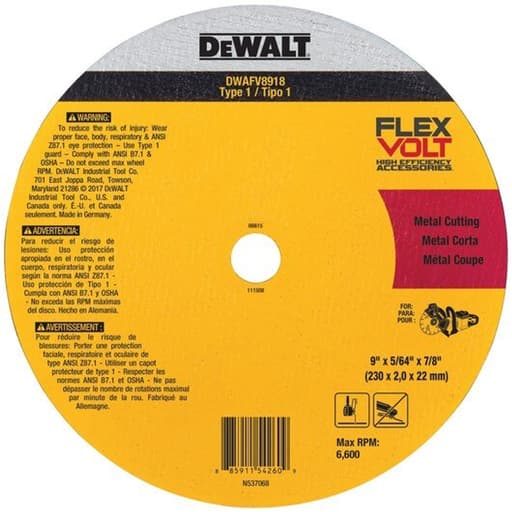

A ceramic abrasive cutoff wheel for metal cutting. The abrasive grain structure is intended to provide high material removal and durability. Suitable for cutting stainless steel, ferrous and non‑ferrous metals. Made for use with cutoff saws that accept a 7/8 in arbor and a 9 in diameter wheel.

DeWalt Ceramic Metal Cutoff Wheel Type 1 Review

A ceramic cutoff wheel that actually keeps up

I’m picky about cutting wheels. Most budget discs either burn up on stainless, glaze over on structural steel, or leave a ragged edge that needs too much cleanup. This 9-inch ceramic cutoff wheel from DeWalt has been one of the few I’ve used lately that feels built for daily metalwork rather than weekend chores. After several weeks cutting stainless tube, mild steel angle, and a couple runs of aluminum extrusion, it earned a permanent spot next to my grinder.

Setup and compatibility

Fitment is straightforward. It’s a Type 1 (flat) 9-inch wheel with a 7/8-inch bore, so it drops onto most high-power 9-inch angle grinders and cutoff saws that accept a flat disc and Type 1 guard. My grinder is rated to 6,600 RPM, which matches the max speed printed on the wheel I tested. As always, check your guard type and flanges—flat wheels need a Type 1 guard, and the shoulder of the inner flange should support a flat disc.

A quick note on thickness: at 5/64 inch (about 2 mm), this is thinner than a typical general-purpose 9-inch wheel. That translates into a narrower kerf, faster cutting, and less burr—but it also means you need to mind your technique to avoid side-loading.

Cutting performance on steel and stainless

On mild steel, the wheel simply feels quick. I ran it through 2 x 2 x .120 wall square tubing, 3/16-inch angle, and some 1/4-inch flat bar. Compared with a standard aluminum-oxide disc, this ceramic wheel tracks straighter and doesn’t bog as it warms up. The cut speed stays consistent instead of dropping off after the first few inches.

Stainless is usually where lesser wheels fade. I tested four cuts through 304 stainless 1-1/2-inch square tube (.065 wall) and two cuts on 2-inch schedule 40 stainless pipe. The wheel stayed sharp and didn’t exhibit the glazing that forces you to lean in and generate heat. Sparks stayed bright and fine, and the motor load felt steady—both signs the grain is fracturing as intended and exposing new edges.

On structural shapes (W4 beam and some 3/8-inch plate), it still held pace, though like any thin wheel, you need to avoid forcing it in web-to-flange transitions where binding is common. A light, steady feed produced quick, straight kerfs without the chattering or wandering you sometimes get with thicker, harder discs.

Burrs, heat, and cut quality

The thin 2 mm profile makes a noticeable difference in finishing. Edges come out with a small, uniform wire burr rather than a heavy ridge. On clean angle cuts in mild steel, I could knock the burr off with a couple passes of a flap disc. On stainless, the edge was surprisingly tidy—no heavy smearing or blue heat bands when I kept pressure moderate and let the wheel do the work.

Heat input is lower than with thicker wheels thanks to the narrow kerf and the ceramic abrasive, which keeps shearing rather than rubbing as it dulls. That helps reduce discoloration on stainless and lowers the chance of heat checking near the cut line. If you’re working near finished surfaces or in thin sections, that’s a real plus.

Durability and wear rate

Ceramic wheels tend to promise a lot on life, and this one largely delivers. After a day of mixed cutting—roughly 20–25 cuts across mild steel, a handful in stainless, and some trimming on aluminum extrusion—the diameter reduction was modest and the face remained free-cutting. With cheaper discs, I often see the first third of the wheel disappear quickly and then the cut rate falls off. Here, the wear felt even and the performance stayed consistent until the wheel got too small for my guard.

As with any thin disc, you can kill it early if you twist in a deep cut. But under normal, straight-ahead cutting, its grain concentration and bond are well matched. I never got that glazed, polished face that signals you’re skating instead of cutting.

Non‑ferrous behavior

The spec says it’s suitable for non‑ferrous metals, and it behaved well on 6061 aluminum extrusion and 1/8-inch sheet, provided I kept the feed light and avoided dwelling. Like most bonded abrasives, it will load if you plow aggressively into gummy alloys. A quick touch with a dressing stick or a swipe of cutting wax kept it cutting clean. If you primarily cut aluminum all day, a dedicated non‑ferrous wheel might still be better, but for mixed-metal jobs this is a fine all-rounder.

Ergonomics and feel

Two things stood out in use:

- It tracks straight. Once the kerf starts, the wheel follows without skating, which reduces wrist fatigue on longer cuts.

- Vibration is low. The disc feels balanced, with no obvious out-of-round behavior as it wears down. That improves control and helps keep cuts square on box and channel.

The thin kerf also means less shower of big, heavy sparks and fewer chunks breaking off the corner when you exit a cut—both small but welcome quality-of-life improvements.

Safety and best practices

A few usage notes that made a difference:

- Let the wheel work. The ceramic grain cuts fastest with moderate pressure. Leaning hard just makes heat and invites binding.

- Keep cuts straight. This is a Type 1 flat wheel, not a grinding wheel. Avoid side pressure and keep the disc aligned with the kerf.

- Mind transitions. In structural shapes, relieve tension or nibble web-to-flange transitions to prevent pinching.

- Guard selection matters. Use a Type 1 guard sized for 9-inch wheels and confirm your grinder’s RPM does not exceed the wheel rating.

Where it excels—and where it doesn’t

Excels:

- Fast, consistent cutting in mild steel and stainless

- Low-burr edges that reduce cleanup

- Even wear and long life compared with commodity aluminum-oxide discs

- Straight tracking and low vibration on a properly powered grinder

Not ideal:

- Heavy lateral loads, plunge-and-twist cuts, or rough demolition where a thicker wheel would be more forgiving

- Dedicated non‑ferrous production work without dressing/wax, as aluminum can load the face

- Situations requiring depressed-center access; as a flat Type 1 wheel, it needs room for the guard and won’t sneak into recessed cuts

Compatibility quick check

- Diameter: 9 in (230 mm)

- Arbor/bore: 7/8 in (22.23 mm)

- Type: 1 (flat, continuous)

- Thickness: 5/64 in (2 mm)

- Max operating speed: 6,600 RPM (match your grinder’s rating)

- Application: ferrous, stainless, and non‑ferrous metals; general cutting on pipe, structural, and welds

Value

It’s not the cheapest wheel on the shelf, but it outlasts bargain discs and stays sharper longer, especially on stainless. In practice, I’d rather pay for one wheel that cuts predictably all day than swap out two or three that slow down and wander. The consistent cut rate, cleaner edges, and reduced time at the deburring station all add up to real savings on a job.

Consumables typically don’t carry generous warranties, and this one is no exception. That’s standard in this category and, in my view, not a drawback—performance in the cut is what matters, and here it’s strong.

The bottom line

The DeWalt 9-inch ceramic cutoff wheel hits the sweet spot for metal fabrication and site work: fast, straight cuts with low burrs, solid wheel life, and consistent behavior on both mild steel and stainless. It rewards good technique and a steady feed, and it holds up under the kind of daily use that exposes weak bonds and mediocre grain.

Recommendation: I recommend this wheel for anyone running a 9-inch grinder or cutoff saw who wants a reliable, fast-cutting disc for steel and stainless, with the flexibility to handle non‑ferrous as needed. It’s especially worth it if you’re tired of swapping out slower aluminum-oxide wheels mid-job or spending extra time on cleanup. Pay attention to guard compatibility and avoid side-loading, and you’ll get excellent results for the cost.

Project Ideas

Business

On‑Site Metal Cut-to-Length Service

Offer same-day trimming of pipe, strut, angle, and structural pieces for contractors and homeowners. Charge per cut or by material size. The 9 in ceramic wheel delivers fast, low-burr cuts that reduce on-site cleanup and keep schedules moving.

Custom Metal Signage & Address Plates

Produce cut blanks from stainless or mild steel, then finish with paint, patina, or powder coat. Upsell standoff hardware and installation. The wheel’s thin kerf shortens prep time before edge finishing and engraving/laser etch.

Modular Storage Rack Kits

Precut angle iron and tube for garage and retail shelving frames. Bundle hardware and simple instructions. Low-burr cuts from the ceramic wheel reduce post-processing, improving throughput and margins on small-batch kits.

Scrap Downsizing for Haulers

Mobile service to cut bulky steel (beams, appliances frames, long pipe) into recycler-acceptable sizes. Price by weight or time. The durable wheel handles repeated cuts on ferrous and non‑ferrous metals, speeding site clear‑outs.

Railing and Gate Repair Pop‑Up

Offer quick on-site removal of damaged sections and precision cutting of replacement pieces for weld-in or bolt-on fixes. The fast, clean cuts reduce fit-up time so you can complete small repairs in a single visit.

Creative

Geometric Log Holder

Cut square tube and flat bar into precise, low-burr lengths to create a modern, angular firewood rack. The thin 5/64 in wheel makes clean miter cuts on mild steel for crisp joints. Weld or bolt the frame, then clear-coat for an industrial look.

Reclaimed Steel Wall Art

Use scrap sheet and light angle iron to form skyline silhouettes or abstract panels. Make straight relief cuts and nibble subtle curves, then layer pieces with standoffs. The ceramic wheel’s fast cut keeps heat tint low on stainless accents.

Modern House Numbers Plate

Cut a rectangular stainless or weathering-steel backer and smaller number tiles from thinner sheet. The low-burr edge reduces time filing before brushing or blackening. Mount with spacers for a floating effect beside the entry.

Rebar Garden Trellis Set

Batch-cut rebar into lengths for modular trellis panels and plant stakes. The high grain concentration speeds through medium-heavy bar. Wire or weld into grid patterns; spray with a clear matte to preserve the raw steel aesthetic.

Minimalist Bike Rack

Cut square tubing with tight miters and make shallow slots to accept wheel guides. Assemble a low-profile wall or floor rack with rubber feet. The thin wheel profile helps keep kerfs neat for snug, consistent joints.