Features

- Carbide-tipped cutting edges for improved wear resistance

- Micrograin carbide tips

- Ball-bearing pilot for edge guidance

- Control-cut geometry to reduce kickback

- Produces a smooth radiused profile with minimal sanding required

- 1/4 in shank compatible with standard routers

- Intended for decorative/profile routing

Specifications

| Model Number | 85270M |

| Shank Inch | 1/4 |

| Radius R1 Inch | 5/32 |

| Cutting Diameter Inch | 5/8 |

| Pack Quantity | 1 |

| Includes | 1 Bit |

| Color | Blue |

| Country Of Origin | Taiwan |

| Upc | 000346049671 |

| Unspsc | 27112821 |

| Weight Lb | 0.115 |

| Package Height In | 7.125 |

| Package Length In | 1.187 |

| Package Width In | 3.375 |

| Manufacturer | Bosch |

| List Price Usd | 55.99 |

Related Tools

Related Articles

Profile cutter intended for decorative edging and period furniture. It has a control-cut geometry to reduce kickback and produces a smoothly radiused edge that typically requires little or no sanding. Micrograin carbide tips improve wear resistance, and a ball-bearing pilot guides the bit along the workpiece edge.

Bosch Roman Ogee Bit Review

Overview

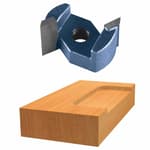

I put this ogee bit to work on a string of cabinet doors and a couple of picture frames to see how it fares on real edges, not just test stock. It’s a compact, classical profile cutter with a 5/32 in radius and a 5/8 in cutting diameter on a 1/4 in shank. The geometry aims to reduce grabby starts and kickback, and the ball-bearing pilot is there to keep the profile tracking cleanly along the workpiece edge. It’s a straightforward tool, meant primarily for decorative edging on small to medium-scale furniture and trim.

In short, it cuts cleanly, feels predictable, and leaves a surface that needs very little follow-up. The 1/4 in shank keeps it light and trim-router friendly, but it also sets some limits on how aggressive you can be—especially in dense hardwoods. Within those limits, the bit performs exactly as I’d hope.

Setup and Compatibility

I ran it in a compact trim router for most work and then moved to a mid-size router in a table for longer runs. The 1/4 in shank fits standard collets and balanced well with both setups. The bearing comes preinstalled and ran true out of the box; there was no wobble or chirping that sometimes betrays a misaligned pilot.

A couple notes from setup:

- The small overall diameter plays nicely at higher RPMs; I settled between 18,000 and 22,000 RPM depending on the wood.

- With a 1/4 in shank, multiple light passes are far better than trying to hog the full profile in one go.

- Edge-guided operation is the intent. While you can use a fence on a table, the bearing pilot makes handheld routing very controllable.

Test Cuts and Performance

I tested across poplar, pine, red oak, hard maple, walnut, and MDF.

- Pine and poplar: Zero drama. The control-cut geometry is noticeable here—entry feels smooth, and the bit doesn’t lurch as it first bites. Tearout was negligible even across end grain on frame rails.

- Red oak: The profile stayed crisp with minimal fuzz. I added a very light “climb kiss” on the cross-grain corners before a full conventional pass to eliminate corner blowout. That small step gave flawless corners.

- Hard maple: Maple will show any hesitation as burn. At 18,000 RPM and a steady feed, the cut stayed clean with only faint warmth on the fillets. Dropping RPM slightly and keeping chips clearing prevented any darkening.

- Walnut: Produced a glassy surface even against the grain. Very little to sand.

- MDF: Predictably dusty, but the bit handled it without chattering. The micrograin carbide edge held up fine across several feet of milling, though MDF will always be the durability stress test over time.

The key performance takeaway is control. The bit doesn’t feel grabby when it first touches the work, and it stays planted on the bearing without skittering, which is especially helpful when routing narrow workpieces or delicate frames.

Cut Quality and Profile

The profile is a classic Roman ogee scaled for cabinet doors, drawer fronts, shelves, and frames. With the 5/32 in radius, it’s more refined than bold—an S-curve that reads as traditional without looking heavy-handed. Across all test woods, edges came off the router with:

- Crisp arrises on the fillets

- Smooth coves with no visible step lines

- Minimal fuzz on open-grain oak

- No bearing track marks or burnish lines from the pilot

Sanding needs were minimal. A few light swipes with 320-grit on the flats blended everything; the profile itself needed only a quick touch in the cove with a folded piece of paper-backed sandpaper. If you take multiple light passes, the finished surface is close to finish-ready.

Control, Kickback, and Bearing Behavior

The control-cut geometry did what it promised. As I eased into the cut, the bit engaged progressively, not abruptly. This is most evident on handheld passes, where a sudden bite can throw your feed rate off. I still recommend taking a shallow first pass—just enough to establish the bearing’s path—then deepening to full profile.

The ball-bearing pilot is smooth and decently sized for the bit’s diameter. It tracked consistently along machined edges and also handled planed but slightly uneven edges without telegraphing minor imperfections into the profile. I keep a drop of light oil on router bit bearings, and this one stayed quiet and cool.

Durability and Heat

After a few hours of mixed routing, including MDF, the cutting edges remained sharp with no chips at the corners. Micrograin carbide tips tend to resist microfractures and hold an edge longer, and that seems to be the case here. Heat buildup wasn’t an issue so long as chips cleared properly and feed rate stayed steady. If you slow your feed too much on dense wood at higher RPMs, you can coax some warmth into the profile—nothing out of the ordinary for a small-diameter bit.

Long-term, the bit should sharpen well. The carbide appears uniform, and there’s enough meat on the cutters for at least a couple of professional sharpenings before the profile shifts notably. As always, pitch removal after use will extend edge life.

Where It Shines and Where It Doesn’t

Shines:

- Decorative edging on cabinet doors, shelves, and small furniture parts

- Picture frames and moldings where a light, classical reveal is desired

- Handheld routing with a trim router thanks to the 1/4 in shank and controlled entry

- Woods from soft pine to hard maple when cut in multiple passes

Less ideal:

- Heavy production work where a 1/2 in shank would provide more rigidity and longevity

- Very large stock or deep profiles; this bit’s scale is intended for smaller reveals

- Aggressive single-pass cuts in dense hardwoods—tempting, but not what this bit is best at

Tips for Best Results

- Set speed around 18,000–22,000 RPM for this diameter, then tune by ear and chip quality.

- Take at least two passes; three is even better in hard woods: a shallow hogging pass, then full-depth.

- Make a light climb “kiss” cut at cross-grain corners to eliminate blowout; follow with a conventional pass.

- Keep a steady feed to avoid dulling heat and burn on maple and cherry.

- Clean pitch from the cutters and add a drop of oil to the bearing after sessions.

Value and Alternatives

At a list price around $55.99, this sits in the mid-range for brand-name carbide profile bits with a bearing. The value proposition rests on consistent cut quality, controlled behavior, and carbide that can be sharpened. If you do occasional decorative edging, this will last you a long time with proper care. If you’re routing ogee edges daily, consider adding a 1/2 in shank version for table work; the added rigidity can reduce chatter and extend edge life under production loads.

The bit is made in Taiwan, and the fit and finish reflect modern, well-controlled manufacturing: square shoulders, neatly ground cutting edges, concentric bearing, and that familiar Bosch blue body.

Recommendation

I recommend this ogee bit for woodworkers who want a reliable, easy-to-control profile cutter for cabinet-scale projects and trim. It shines in trim routers and handheld passes, where the control-cut geometry and smooth bearing keep the process predictable and safe. The cut quality is excellent, the profile is tastefully scaled, and the micrograin carbide holds up well—even with some MDF in the mix.

Choose it if you:

- Rout decorative edges regularly but not at industrial volumes

- Prefer handheld routing with a trim router

- Want an ogee profile that needs minimal sanding and resists tearout

Look elsewhere if you:

- Need a heavy-duty, production-oriented solution on a router table—consider a 1/2 in shank variant

- Rout oversized stock or want a bolder, deeper ogee than a 5/32 in radius provides

Within its intended scope, this bit delivers clean results with minimal fuss. It’s a trustworthy option for adding a classical, refined edge to your next project.

Project Ideas

Business

Mobile Edge Upgrade Service

Offer on-site or shop-based edge-profiling for stair treads, window stools, shelves, and solid-wood countertops. The Roman ogee adds perceived value instantly. Market to realtors, landlords, and flippers as a quick aesthetic upgrade. Price per linear foot with tiered rates for species and finish options.

Boutique Picture Frame Shop

Produce a line of hardwood frames with compound ogee profiles and sell online or locally. Offer custom sizes, stains, and engraving. Batch efficiently using the carbide-tipped bit for long wear and consistent cuts, and standardize SKUs for quick turnaround.

Cabinet Door Refacing and Drawer Fronts

Build replacement solid-wood doors and drawer fronts with Roman ogee edges for kitchens and baths. Provide sample boards showing profiles and finishes. Package installation plus finishing as an upgrade over painting alone. Upsell soft-close hardware and matching trim.

Event Decor and Signage Line

Create ogee-edged wedding signs, cake stands, menu boards, and table numbers. The refined edge reads premium in photos. Offer rental packages or personalized orders with laser-engraved text. Market to planners and venues; keep standard sizes for efficient production.

Restoration Molding Matching

Serve homeowners and contractors restoring period homes by fabricating short-run moldings, casings, and cap trims using the Roman ogee bit. Combine passes and fence offsets to approximate legacy profiles without custom knives. Charge setup fees plus per-foot rates.

Creative

Heirloom Keepsake Box with Tiered Ogee Lid

Build a small hardwood box and route multiple passes on the lid and base to create a stepped Roman ogee cascade. The 5/32 in radius produces an elegant, period-correct profile that doesn’t overpower small boxes. The ball-bearing pilot makes it easy to follow the perimeter, and the smooth cut means minimal sanding before finishing with oil or shellac.

Compound Ogee Picture Frames

Make custom frames by routing the outer perimeter and the inner reveal with the ogee bit for a compound profile. Use contrasting woods (walnut/maple) or layered laminations for visual depth. The control-cut geometry helps avoid chatter on miters, and the micrograin carbide edges hold up across multiple frame sizes.

Classic Ogee-Edged Serving/Charcuterie Boards

Cut a flowing Roman ogee around the board perimeter for a refined hand-feel. Add a shallow juice groove inside the edge, and incorporate handholds on the ends. The subtle 5/32 in radius pairs well with thin boards, making them look upscale while remaining functional.

Mantel Clock or Mini Bookcase with Ogee Moldings

Craft a small clock case or desktop bookcase and apply custom ogee moldings to the top cap and base. Rip thin molding strips, then profile with the bit at the router table. Miter and wrap for a furniture-grade look that mimics traditional period pieces.

Side Table Top with Period Edge

Turn a simple round or rectangular tabletop into a statement by adding a Roman ogee edge. The ball-bearing pilot keeps the cut consistent on curves. Pair with tapered legs for a refined, Shaker-meets-colonial aesthetic that feels timeless.