Features

- Carbide tip to increase carbide-to-material contact and extend bit life

- Open-head point channels dust into flutes for more efficient debris removal

- Four-cutter / four-flute design reduces vibration and expedites mill removal

- Longer helix (spiral) flute for improved debris evacuation

- Spline shank for secure connection to compatible hammer drills

Specifications

| Drill Diameter | 5/8 in |

| Overall Length | 10 in |

| Working Length | 5 in |

| Flute Type | Longer Spiral |

| Flute Length | 5 in |

| Material | Steel (body) |

| Number Of Flutes | 4 |

| Point Type | Rock Carbide (open head) |

| Shank Size | 3/4 in |

| Shank Type | Spline |

| Cutting Depth | 5 in |

| Cutting Edge Material | Carbide |

| Finish | Bright |

| Applicable Materials | Concrete and masonry |

Related Tools

Related Articles

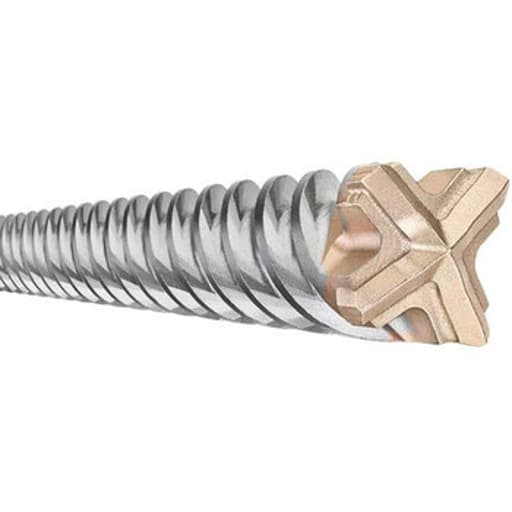

Spline masonry drill bit with a carbide tip and four cutting heads. The longer helix and four-flute design aid removal of drilled material, and the open-head point routes dust into the flutes to support faster drilling in concrete and masonry.

DeWalt High Impact Carbide Spline Drill Bits Review

Why I reached for this bit

On a retrofit job in an older warehouse, I needed to drill a batch of 5/8-inch anchor holes in cured, aggregate-heavy concrete. The site’s rotary hammer was a spline-drive model—a workhorse that refuses to retire—so I grabbed DeWalt’s 5/8-inch spline bit and put it to work. Over several hours of slab and wall drilling, it gave me a clear sense of where this bit shines and where it’s merely adequate.

Design and build quality

This DeWalt spline bit is straightforward but well thought out. The four-cutter head is carbide, set into a steel body with a bright finish. The tip uses an open-head design, which provides a cavity for fines to enter immediately at the point of contact and feed into the flutes. The bit runs a true four-flute helix with a relatively aggressive spiral. That “longer helix” matters: more lift per rotation means debris gets evacuated faster, and the bit spends more time cutting and less time regrinding dust.

Key dimensions and geometry:

- Diameter: 5/8 in

- Overall length: 10 in

- Working/flute length: 5 in

- Flutes: four, longer spiral

- Shank: 3/4 in spline

The spline shank is a big part of the story. It locks into older spline-drive hammers with a positive, non-slip engagement, and on my tool there was no rattle or free play in the fit. If you’re coming from SDS-Plus or SDS-Max, spline can feel vintage, but it’s still a robust interface with excellent torque transfer for larger-diameter bits.

Setup and compatibility

Compatibility is the make-or-break factor here. This bit is spline only. It will not fit SDS hammers without an adapter, and I don’t recommend adapters for heavy hammer drilling—they introduce slop and can accelerate wear. If you’ve got a spline-drive hammer, you’re in business. If you’re running SDS-Max, get the SDS-Max version of a comparable 5/8-inch bit rather than trying to bridge systems.

On my spline hammer, the bit seated easily and ejected without sticking. The shank showed minimal scoring after a day of work, a good sign of hardness and proper heat treat.

Drilling performance in concrete and masonry

In 4,000–4,500 psi slab concrete, the four-cutter head showed its value. Start-up wander was minimal even without a pilot divot, and the tip tracked cleanly over aggregate. The open-head cavity helped keep the cutting edges in contact with material rather than riding on powder. Paired with the longer helix, I saw steady chip flow up the flutes with less pulsing than I typically get from two-cutter designs. That translates to fewer pauses to peck the hole and clear dust.

A few observations from the field:

- Speed: Solid for a four-cutter. It’s not the absolute fastest bit I own, but it maintained a consistent pace hole after hole because it stayed clear of fines.

- Vibration: Noticeably lower than two-cutter bits of the same size. The four-flute symmetry and head geometry reduce chatter and the “cam” effect that can wear you out on long sets.

- Hole quality: Round, true holes with clean walls. Wedge anchors seated snugly without the oversize feel you sometimes get when a bit starts to dull.

- Spalling: Minimal breakout on the exit side of through-holes in slab. In CMU, it kept face blowout modest when I eased up at break-through.

- Heat: Warm but not excessive, even during consecutive holes. The flutes were doing their job.

In CMU and brick, the bit was well-mannered. The four-cutter face reduces the tendency to grab at webs, and the longer helix helps carry the dusty fines out rather than packing them in the hole. It’s overkill for soft masonry, but if your work jumps between block and structural concrete, it’s convenient not to swap bits.

Durability and wear

Carbide life is always the big question. After a day that included a couple dozen holes in cured slab and a handful in block, the edges still felt crisp and the head geometry was intact. The bit didn’t blue from heat, and the flutes didn’t clog with impacted dust—both good indicators that the cutting edges are doing the work, not the steel body.

I did encounter what I suspect was a small piece of tie wire or hard aggregate. The bit chattered briefly but didn’t chip a corner. That’s not a license to drill through rebar—this isn’t a rebar cutter—but the four-cutter head geometry tends to survive incidental contact better than two-cutter tips.

One note: the bright finish means there’s no protective coating. It’s not a problem if you dry the bit after wet conditions, but don’t toss it back into a damp case and forget about it. A light wipe of oil keeps rust off the flutes.

Dust evacuation and cleanliness

The open-head point is more than marketing. You can watch fines slip into the tip cavity and ride out in the flutes. With a vacuum on the hole, cleanup was quick and my anchors seated with less brushing. Without vacuum, the bit still pulled dust well, but like all hammer drilling, extraction makes a noticeable difference in both speed and hole quality.

The four-flute design carries debris effectively, though it does fill quicker than a large two-flute when you’re drilling overhead in soft block. A quick pulse of the hammer clears it. In dense concrete, the four-flute shines by keeping the hole cleaner at the cutting interface.

Limitations to keep in mind

- Working length: At 5 inches, you’re capped on embedment depth. That covers common 5/8-inch wedge anchors and sleeve anchors but not deep embed or thick-through slab in one pass. If you regularly drill through thicker members, you’ll want a longer bit.

- Shank type: Spline-only compatibility limits flexibility if your crew has standardized on SDS-Max. I wouldn’t run this through an adapter for production work.

- Not for rebar: Incidental contact won’t kill it, but it’s not a rebar-cutting bit. If you know you’ll hit steel, bring the right cutter.

- Availability and redundancy: Spline bits are less common on the shelf than SDS variants. If your schedule can’t tolerate a broken tip with no backup, carry a spare.

None of these are deal-breakers; they’re simply the realities of a 10-inch, 5/8-inch spline bit with a four-cutter head.

Practical tips for best results

- Let the bit do the work. Don’t lean hard on the hammer; excessive feed pressure reduces chip flow and can glaze the carbide.

- Use dust extraction. The open-head design excels with a vacuum on the hole and reduces hole cleaning steps for anchors.

- Clear the flutes. A quick peck or two mid-hole keeps speeds up, especially overhead or in soft block.

- Mark your depth. With a 5-inch working length, tape a depth flag on the bit so you don’t bottom the flutes and burnish the hole.

- Inspect the tip. If you graze steel, stop and check for chipped edges before continuing.

Who it’s for

This DeWalt spline bit makes sense if you:

- Run a spline-drive hammer and routinely drill 5/8-inch holes in concrete or masonry.

- Value round, true holes for mechanical anchors.

- Prefer low vibration and steady chip evacuation over chasing absolute speed.

If your fleet is SDS-based or you need longer embedments, look for the equivalent geometry in the shank and length you use most.

Recommendation

I recommend this DeWalt spline bit for anyone working with a spline-drive hammer who needs reliable, repeatable 5/8-inch holes in concrete and masonry up to a 5-inch depth. The four-cutter head, open tip, and longer helix produce clean, round holes with less vibration and fewer stalls, and the carbide has the durability to handle a full day’s work without fading. The main caveats are compatibility—this is spline-only—and the 5-inch working length. Within those bounds, it’s a dependable, no-drama performer that makes anchor work smoother and more predictable.

Project Ideas

Business

Anchor and Fixture Install Service

Offer a fast, dust-managed installation service for heavy fixtures on concrete and masonry: gym racks, bike stations, handrails, shelves, signage, and safety bollards. The 5/8 in diameter matches common wedge/sleeve anchor sizes; the four-cutter carbide head speeds drilling in tough aggregate. Package options include hardware selection, layout, drilling, anchoring, and verification torque testing.

Decorative Privacy Block Perforation

Provide on-site perforation of CMU or cast concrete panels to create custom breeze-block style screens. Sell templated patterns (mid-century, geometric, company logos) and premium options like polished hole edges. The open-head design and longer helix make quick work of repetitive holes while minimizing clogging, letting you price per pattern or per square foot.

Post-Installed Rebar/Dowel Pinning

Partner with landscapers and small contractors to drill 5/8 in holes for post-installed dowels that tie small slabs, steps, and curbs together. Deliver consistent hole depth (up to 5 in working length), blow and brush, and adhesive injection as an add-on. Market this as a durability upgrade for projects that experience movement or traffic.

Low-Voltage and HVAC Pass-Throughs

Specialize in clean 5/8 in penetrations through masonry for mini-split linesets, condensate drains, irrigation sleeves, and low-voltage conduits. Bundle dust control, proper slope drilling for drains, and corrosion-resistant sleeves/grommets. Offer same-day service to electricians, HVAC techs, and AV installers who need reliable holes without mobilizing a core rig.

Retaining Wall Drainage Retrofits

Retrofit weep holes in existing concrete or block retaining walls to relieve hydrostatic pressure. Use the four-flute bit to efficiently drill 5/8 in outlets at regular intervals, then insert perforated sleeves and screens. Upsell gravel pocket creation and geotextile filters. Position this as a preventative maintenance service to reduce wall failures.

Creative

Perforated Cinder-Block Lanterns

Turn standard CMU blocks into glowing lanterns for a patio or garden. Use the 5/8 in bit to drill repeating patterns through the block webs; the open-head point and four-flute design will clear dust fast and keep holes clean. Insert short acrylic rods or glass tubes into select holes and backlight them with low-voltage LEDs housed behind the block. Stack blocks into a screen wall or line a pathway for dramatic nighttime effects.

Concrete-and-Rebar Bench

Create a minimalist outdoor bench by drilling 5/8 in holes into precast concrete slabs or thick pavers to accept 1/2 in rebar or stainless rod as hidden dowels. The carbide tip handles aggregate hits while the longer helix evacuates debris. Epoxy the rods into the holes to stitch slabs together for a sleek, floating look. Finish the seat with a sealed surface or a wood overlay.

Star Map Retaining Wall

Map a constellation pattern onto a concrete or block wall and drill 5/8 in holes at star points to a consistent 2–3 in depth. Press-fit diffused acrylic plugs into each hole and light them from the backside with LED strip in a shallow chase. The four-cutter head reduces vibration, keeping the hole geometry clean for snug acrylic fits.

Rain-Chain Splash Feature

Drill a clustered array of 5/8 in holes through a concrete splash block or small slab to direct water into playful jets under a rain chain. The longer spiral flutes speed debris clearing so you can experiment with densities and angles. Polish the entry edges and seal to enhance the water’s sparkle as it flows through the perforations.

Wall-Mounted Garden Grid

Lay out a grid on a brick or block wall and drill 5/8 in anchor holes for sleeve or wedge anchors that hold a steel cable trellis. The spline shank keeps the bit firmly seated in a hammer drill for rapid, consistent drilling. Train vines or hang modular planter boxes from the grid for a living facade.