Features

- Aluminum oxide abrasive for extended life and efficient material removal

- Proprietary material mix for durability

- Two full sheets of fiberglass reinforcement for strength and safety

- Diamond knockout arbor for compatibility with worm-drive saws

- High grain concentration for aggressive cutting and smoother running

Specifications

| Arbor Size | 5/8 in |

| Disc Diameter | 7 in |

| Disc Thickness | 1/8 in |

| Number Of Pieces | 25 |

| Product Pack Quantity | 25 |

| Includes | (1) cutting blade |

| Intended Materials | Carbon steel and other ferrous metals |

| Warranty | 30 Day Money Back Guarantee |

Related Tools

Related Articles

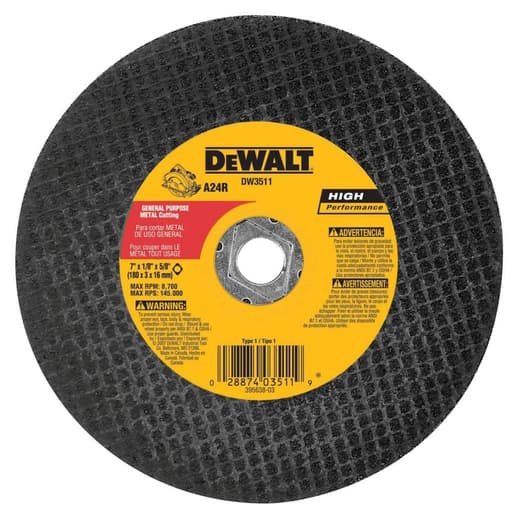

A Type 1 metal-cutting abrasive saw blade made with aluminum oxide abrasive and a proprietary material mix. The blade has fiberglass reinforcement for strength and a diamond knockout arbor to allow use with worm-drive saws. It is intended for cutting carbon steel and other ferrous metals.

DeWalt 6-1/2 x 1/8 x 5/8 diamond drive metal cutting blade Review

Why I reached for this blade

I don’t always put a circular saw to metal, but when a job calls for straight, predictable cuts in ferrous stock, an abrasive cut-off blade is still a practical choice. I picked up this DeWalt blade for a mix of tasks—trimming corrugated steel siding, cutting 1/8-inch angle, and lopping the end off a length of schedule-40 pipe. I wanted something compatible with a worm-drive saw, with enough backbone to stay true through the cut, and easy to source in multiples. This blade checks those boxes.

Setup and compatibility

The blade uses a 5/8-inch arbor and includes the diamond knockout that older worm-drive saws expect. On my worm-drive saw, the knockout popped cleanly without deforming the center, and the fit was snug on the diamond arbor. I also ran it on a sidewinder with a standard 5/8-inch round arbor—no fuss there either. The disc is 1/8-inch thick, which is on the stout side for an abrasive cut-off wheel. That thickness brings stability and less wander in a handheld saw, especially helpful when you’re guiding a long cut on siding or tubing.

It’s a Type 1 wheel, so it’s strictly for straight cuts. Don’t try to grind sideways with it; you’ll reduce life dramatically and risk edge damage. DeWalt reinforces the disc with two layers of fiberglass, and it feels rigid in the hand without being brittle.

Cutting performance

Aluminum oxide is the right abrasive for carbon steel, and the grain concentration here feels dialed for speed. On 26–29 gauge steel siding, cuts start quickly with minimal stalling. The wheel tracks well when I score and then commit; if I plunge right in, it can skate a hair on painted surfaces until a groove forms—normal for this class of wheel. Spark output is high (it’s an abrasive blade, after all), but temperature in the workpiece stays manageable if you keep the feed rate sensible.

On 1/8-inch angle and flat bar, the blade finds its lane and moves through without drama. The 1/8-inch kerf is wider than a 0.045-inch grinder wheel, so you’ll remove more material and generate more heat and sparks, but the tradeoff is cut stability. For handheld, straight cuts with a footplate riding a line, I’d rather have the extra rigidity.

When I moved to 1/4-inch plate, the wheel still did the job, but speed tapered as the cut length increased. That’s typical: a fresh edge bites aggressively, and you’ll feel it slow as the abrasive dulls and the diameter shrinks. The key is light, steady pressure—let the wheel do the work. If you bear down to “help,” you glaze the abrasive and invite edge chipping.

On schedule-40 pipe, I had to be deliberate. I scored the circumference first, then worked around in passes. The blade can complete the cut, but binding risk is real as the kerf closes, so wedges or a wrap-and-score approach pays off. Crowding the blade will overheat the edge, and any twist while the wheel is pinched can flake the rim. Treated gently, it gets through, but this is near the top end of what I’d consider comfortable for an abrasive wheel in a circular saw.

Cut quality and cleanup

Abrasive cuts leave a small burr. In thin siding, the burr is easily knocked down with a file. In thicker stock, expect a heavier burr and some heat tint on the edge. The finish is typical of abrasive cutting—straight but not “factory,” with a slightly rough face. If I need a cleaner edge, I follow with a flap disc.

Tracking is solid as long as the baseplate has stable support. The wheel’s stiffness helps keep the cut straight, though it won’t hide a shaky hand or poor clamping. I like to score a shallow groove first; it reduces wandering and keeps the blade from skating on painted or galvanized surfaces.

Durability and wheel life

This is a consumable, and its life depends heavily on your technique and the material. On thin-gauge steel siding, I got a surprisingly long run—multiple long rips and crosscuts before I noticed the edge slowing. On 1/8-inch angle, wheel life was respectable, and the diameter stayed large enough after several cuts to keep the guard geometry safe. On 1/4-inch plate and pipe, life drops faster, especially if you push.

The proprietary bond DeWalt uses feels on the “hard” side for this class—good for holding grain on straight, steady cuts, but unforgiving if you side-load. If you twist the saw at the end of a cut to “pop” the last bit, you can micro-chip the edge. That’s user error, but it’s worth mentioning because an 1/8-inch wheel can lull you into thinking it will tolerate grinder-like abuse. It won’t. The two fiberglass layers do their job: I had no wheel bursts or serious fractures. I did retire one wheel early after I noticed a jagged spot forming at the rim from an impatient finish on pipe—once an edge chips, don’t try to “true it up” in the cut; discard it.

Safety and handling

- Use full PPE: face shield over safety glasses, hearing protection, gloves, non-flammable clothing.

- Confirm the wheel’s max RPM is compatible with your saw. Worm-drive saws are typically within range, but always check.

- Keep flanges clean and flat, and tighten to spec. A dirty flange can introduce wobble and accelerate wear.

- Avoid lateral pressure. This is a cut-off wheel, not a grinder.

- Let the blade spin down outside the cut and away from your work—spinning a hot edge against material can glaze the bond and chip the rim.

- Secure the work. Movement during the cut is the fastest route to binding and edge damage.

What it’s good for—and what it isn’t

- Strong use cases: carbon steel siding, sheet, light structural (angle, channel under 3/16-inch), conduit, and quick trims on hardware. The blade’s stiffness and diamond knockout make it particularly friendly in a worm-drive circular saw where straight cuts shine.

- Marginal use: thick-wall pipe and sustained cuts in 1/4-inch plate or heavier. It will do it, but at the cost of wheel life and with more risk of edge damage if you rush.

- Not recommended: aluminum and other gummy non-ferrous metals. Aluminum oxide wheels load up fast on non-ferrous; use a non-ferrous-specific blade or a lubricant designed for abrasives if you must, but I reach for a carbide tooth blade or a bandsaw instead.

Value and availability

You can buy these singly or in multi-packs, which is how I prefer to keep them on hand. Per-cut cost on thin and moderate steel is low, and the performance is consistent wheel to wheel. A 30-day money-back guarantee adds a little confidence, though in my view this is a commodity you judge by how it runs in your own saw and materials.

Alternatives to consider

- Thin 0.045-inch grinder wheels: faster, cooler cuts in thin stock with a narrower kerf, but harder to keep dead straight without a guide and not compatible with a circular saw’s footplate workflow.

- Carbide-tooth metal-cutting blades: cooler, burr-free cuts with chips instead of sparks, but they’re far pricier and require a saw and guard rated for them. In rugged jobsite conditions where sparks and rough edges are acceptable, an abrasive wheel remains a practical choice.

The bottom line

The DeWalt blade is a sturdy, straightforward abrasive cut-off wheel that pairs well with worm-drive and standard circular saws. It cuts ferrous metals efficiently, tracks straight thanks to its thicker profile, and the diamond knockout makes compatibility a non-issue. Treated with a light hand and kept out of binds, it holds up well across siding, sheet, and light structural steel. If you push it hard in thick stock or twist in the cut, the edge will let you know—respect the limitations of an abrasive Type 1 wheel and it will give you predictable, repeatable results.

Recommendation: I recommend this blade for pros and DIYers who need reliable, straight cuts in carbon steel using a circular saw, especially on siding, sheet, and light structural steel. It offers a good balance of stability and speed, with safety reinforcement that inspires confidence. If your work leans heavily toward thick-wall pipe or 1/4-inch-plus plate, consider supplementing with a carbide-tooth solution or a saw that accepts thinner abrasive wheels to conserve time and consumables.

Project Ideas

Business

On-Demand Metal Cut-to-Size Service

Offer precise cutting of rebar, angle iron, flat bar, and mild-steel tubing for DIYers and contractors. Use the diamond knockout arbor to run the blade on a worm-drive saw for portable, on-site cuts. Charge per cut and by material thickness; sell in fast-turnaround bundles for renovation projects.

Custom Steel Decor & Signage Shop

Produce wall art, address signs, monograms, and logo plaques from sheet steel. Market via Etsy and local markets. Upsell finishes (clear, patina, powder coat) and mounting kits. The blade’s durability and bulk pack reduce per-piece cutting costs and increase throughput.

Fabricated Brackets and Hardware for Trades

Supply small-batch steel brackets, gussets, tabs, and hangers to woodworkers, cabinet shops, and builders. Maintain jigs for consistent lengths; offer same-day turnaround. Bundle with hardware and primers to deliver ready-to-install kits.

Intro to Metalworking Workshops

Host weekend classes where students safely cut and assemble a trellis or firewood rack. Provide pre-cut kits plus live cutting demos with PPE and clear safety protocols. Revenue from tuition, material fees, and tool/blade sales after class.

Landscaper Rebar & Stake Fabrication

Serve landscapers with custom-cut rebar, edging stakes, and garden structures. Offer on-site cutting using a worm-drive saw setup for fast, accurate lengths. Sell standardized packs (e.g., 50 stakes at 24 in) and seasonal products like tomato cages and vine arches.

Creative

Industrial Silhouette Wall Art

Use the blade to cut clean silhouettes from 14–16 ga mild steel sheet (nature scenes, skylines, monograms). The fiberglass-reinforced disc stays stable on curves, and the diamond knockout arbor lets you mount it to a worm-drive saw for controlled, straight-line cuts with a guide. Deburr, add a heat-blued or clear-coated finish, and mount with standoffs for a shadow effect.

Geometric Garden Trellises

Cut 3/8 in rebar or flat bar into repeating lengths and angles to form obelisks, arch trellises, or modular lattice panels. The aluminum oxide abrasive makes quick work of ferrous stock. Assemble with welding or bolt-on corner plates; seal with rust-inhibiting paint for long outdoor life.

Firewood Storage Rack

Build a modern firewood rack with angle iron and flat bar. Straight, square cuts with the high-grain blade yield tight corners for welding or bolting. Finish in flat black or clear to showcase mill scale; add adjustable feet or casters for flexibility.

Custom Metal House Numbers & Signs

Lay out numerals/letters on sheet steel with stencils, score lines, and cut. The aggressive cutting action gives crisp edges that polish up nicely. Add a patina or powder coat and mount to cedar or reclaimed wood backers for a mixed-material look.

Shop Storage Brackets & Racks

Cut angle iron and strap steel to make heavy-duty French cleat brackets, clamp racks, and hose/tool hangers. The blade’s smoother running helps maintain consistent lengths for modular systems. Prime and paint to prevent rust and color-code by load capacity.