Features

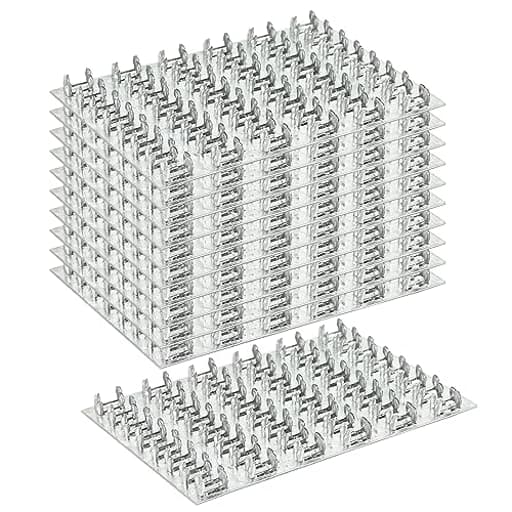

- Pack List: Comes with 10 pieces 4x6 truss plates, that are made of premium steel with HDG (hot dip galvanized) treatment, anti-rust and resistant-corrosion

- Pronged Trussplates: This nail teeth mending plates feature staggered nails for a secure connection that resists splitting

- Wood Truss Construction: Used to connect members of roof trusses, floor trusses, and wall frames in prefabricated wood structures, replacing traditional nails or bolts

- Fast Assembly: Pressed into wood using hydraulic or roller equipment, allowing quick and precise connections for multiple members (e.g., chords and webs)

- MOZCORN Wood Brackets: MOZCORN offers a comprehensive wood truss connectors with various sizes, such as truss mending plates, l brackets, hurricane ties and joist hanger etc.

Specifications

| Color | Silver |

| Size | 4x6in -10pack |

| Unit Count | 10 |

Related Tools

Ten 4×6-inch pronged truss mending plates (10 pack) are stamped from steel and hot-dip galvanized for corrosion resistance, with staggered nail teeth designed to be pressed into wood for secure, split-resistant connections. They are used to join roof, floor and wall truss members and are installed quickly with hydraulic or roller press equipment as an alternative to traditional nails or bolts.

MOZCORN 10 Pcs Truss Plates 4x6 Inch, Pronged Truss Mending Plate with Nail Teeth, Mending Plates for Wood Trusses Construction Review

A week with pronged truss plates in the shop

I pulled a 10-pack of Mozcorn 4x6 pronged truss plates into the shop for a week of tests on framing lumber and a couple of quick fixes around the property. These are the classic pressed-tooth connector plates you see on factory-built trusses—flat steel sheets bristling with teeth—only sized for general-purpose mending and reinforcement. At 4 by 6 inches and hot-dip galvanized, they’re meant to bite into solid wood and create a broad, split-resistant join where screws or nails would concentrate loads.

Build, finish, and first impressions

Out of the box, the plates feel substantial. The stampings on my set were consistent with clean tooth geometry and only minor burrs at the edges. The hot-dip galvanized coating is even, with that familiar spangled matte finish. They aren’t flimsy; flexing a plate by hand takes a deliberate effort, which matters when you’re asking a field of teeth to embed evenly. As with most pronged plates, the teeth are staggered—not in neat rows—and that layout helps avoid initiating straight-line splits in dry lumber.

The edges and teeth are sharp enough to command respect. Gloves are mandatory. I knocked down two tiny burrs with a file, but overall the plates were ready to use.

Installation: press is best, but you have options

In a perfect world, these get pressed into place under a hydraulic or roller press. That’s how truss plates are installed in production settings, and it produces deep, uniform embedment. I don’t expect most remodelers or DIYers to have a dedicated roller, but a small shop press or even a heavy bench vise will get you most of the way there.

Here’s what worked well for me:

- Shop press: With a flat steel backer under the workpiece, the 12-ton press sank the plate flush in SPF 2x material in a single, controlled stroke. Teeth seated fully across the field with no cupping.

- Bench vise and clamps: For on-site work, I clamped a plate in from both sides using a pair of deep C-clamps and a sacrificial plywood caul. Alternating a quarter-turn on each clamp brought the plate in evenly without bending teeth. It’s slower but effective.

- Dead-blow and block: As a last resort, a dead-blow mallet and a hardwood block can “walk” a plate into place. Start in the center and work out in a spiral pattern. Expect less-than-perfect embedment and more cosmetic scuffing.

Two tips to avoid headaches: use a rigid backer to support the wood and plate while pressing, and avoid chasing individual teeth with a hammer—once a tooth bends, it rarely seats well. If you need maximum strength, mirror the connection with a second plate on the opposite face; the sandwich effect increases bite and reduces the risk of the wood lifting around the prongs.

Performance on different materials

I tried the plates on a handful of common scenarios:

- SPF 2x6, kiln-dried: Seats easily with a press, holds firmly, and shows minimal surface bruising around the teeth. Removal took real persuasion with a flat bar, which is what you want.

- Rough-cut 6x6, still a bit green: Nearly ideal. The teeth buried deeply with a bench vise and the plate snugged flush. This is a good use case if you’re trying to arrest end checking or keep a split from propagating on heavy timbers.

- Southern yellow pine 2x material: Requires more force than SPF but finishes cleanly under a press. I’d avoid hammer-only installs here.

- Red oak offcut: The teeth will go in under a shop press, but the required load is high and the risk of strip-out on removal is real. I wouldn’t choose pronged plates for hardwood repairs where precision matters.

- OSB and particle board: Not recommended. The teeth fracture the top veneer on OSB and crumble particle board. There just isn’t enough long-grain fiber for the teeth to engage.

As marketed, these plates are designed for solid wood. They excel where there’s continuous grain for the prongs to bite. If you’re connecting sheet goods or engineered products, switch to a nail-on plate or a screw/bolt pattern with washers.

Real-world fixes and shop uses

Two practical jobs stood out. First, I used a pair to stabilize the end of a 6x6 post that had started to check after a summer in the sun. One plate per face, pressed in with a vise, and the checking stopped widening. It’s a low-visibility fix that took minutes.

Second, I built a quick prototype frame for a storage rack from SPF 2x4s. The plates were perfect for fast, tool-light assembly: clamp, press, move on. I wouldn’t rely on that frame for heavy loads without additional fasteners, but for a quick mockup they saved a lot of drilling and screwing. I also tested one plate across a small edge split in a 2x6 gate rail; it kept the crack from creeping with opening and closing. The staggered teeth help distribute load away from a single failure line.

Outdoors, the galvanization shrugged off early fall rain with no red rust after a couple of weeks. For permanent exterior installations in wet or coastal environments, I’d still keep an eye on coating longevity and chemistry; ACQ-treated lumber is hard on zinc. If that’s your use case, confirm the coating thickness or consider a connector rated specifically for harsh environments.

Strength, ratings, and code reality

These are “truss-style” plates, but that doesn’t magically make a field-assembled truss. The big limitation isn’t the physical plate so much as the lack of published engineering values and the variability of field installation. Factory truss plates come with evaluation reports and are pressed under controlled conditions. This set doesn’t include load tables, and I couldn’t find any stamped approvals tied to a building code evaluation. That means they’re great for repairs, blocking, jigs, prototypes, and non-inspected projects, but I would not use them as the primary structural connection where an inspector expects listed hardware or certified truss manufacturing.

If you need a rated solution for a load path, look at nail-on mending plates or specific connectors from major brands that publish design values, or step up to structural screws or bolts with proper edge distances and washers. For what they are—unrated pronged mending plates—these do the job well.

Ergonomics and safety notes

The teeth are unforgiving. Handle and store them in a way that doesn’t invite accidental contact—keep the cardboard slip sheets, or stack them tooth-to-tooth with a scrap between. When pressing, check that no teeth have curled; a bent tooth can lift the plate or create a pressure point that scars the wood. Eye protection is non-negotiable.

Value and who they suit

In a 10-pack, the plates hit a sweet spot for small shops and serious DIYers: enough to tackle a few projects without committing to a contractor case. I appreciate having them on hand for:

- Arresting splits in posts and beams

- Reinforcing non-critical splices and frames

- Temporary fixtures and jigs where screws would be in the way

- Quick bracing during glue-ups

If your work is primarily code-inspected structural framing, these won’t replace listed connectors. If your work involves solid lumber repairs, prototyping, or farm-and-ranch problem-solving, they’re a handy addition to the hardware drawer.

The bottom line

The Mozcorn 4x6 pronged truss plates are sturdy, well-coated, and effective on solid lumber when installed with a press or heavy clamping. The staggered teeth seat cleanly and resist initiating splits, and the galvanized finish provides sensible protection for general use. They’re not a substitute for engineered truss connectors or rated hardware in inspected applications, and they don’t belong in OSB or particle board. Within those bounds, they’re quick, reliable problem-solvers that save time.

Recommendation: I recommend these plates for shop and site tasks that call for fast, broad-surface reinforcement in solid wood—stopping checks, backing up non-critical joints, and building temporary or light-duty assemblies. I would not recommend them as primary connectors in code-governed structural work or for use in sheet goods. If you understand that line, you’ll find them useful and cost-effective to keep on hand.

Project Ideas

Business

Prefab Truss Kits for Small Structures

Assemble and sell prefabricated roof/floor truss kits for sheds, greenhouses, and tiny houses using these truss plates. Offer models with cut lumber, plates installed, and clear assembly instructions so customers can erect structures quickly without specialized joinery—appealing to contractors and DIYers.

DIY Connector Kits + Online Plans

Package the 4×6 plates with precut lumber templates, bolts, and step-by-step plans for projects (tables, pergolas, bookshelves). Sell kits on an e-commerce site or marketplaces with how-to videos. This low-overhead product targets hobbyists who want the industrial look with simple assembly.

Signature Industrial Furniture Line

Design and produce a line of industrial furniture (benches, tables, shelving) that uses truss plates as a visible signature component. Market to urban/loft demographics, interior designers, and retailers. The plates become a brand element—durable, rugged, and visually distinctive.

Hands-On Workshops & Certification

Run workshops teaching contractors and serious DIYers how to use pronged truss plates and press equipment to build safe trusses and wood structures. Offer tiered courses (intro to trusses, furniture building, small-structure assembly) and sell starter kits to attendees for follow-up projects.

Mobile Pressing Service / Equipment Rental

Offer a mobile or rental service where you bring a hydraulic/roller press to job sites or maker spaces to press plates into wood for customers who lack the equipment. Charge per-plate or per-hour. This lowers the barrier for small builders and hobbyists while generating steady service revenue.

Creative

Industrial Corner Coffee Table

Use the 4×6 truss plates as visible corner brackets on a thick reclaimed-wood coffee table. Press the pronged plates into the table legs and apron for a rugged, industrial look that also adds structural strength. Finish the wood with a clear coat to contrast the galvanized plates and highlight the hardware as a design feature.

Modular Knock-Down Bookshelf System

Create a flat-pack shelving system where shelves and uprights join with truss plates recessed into routed slots. The plates act as strong, repeatable connectors so customers can assemble and disassemble without screws or complex joinery. Offer different shelf widths and a simple bolt or pin that locks the assembled plates in place.

Geometric Wall Art or Sculpture

Arrange several truss plates into repeating geometric patterns and fasten them to a wooden or metal backing to make a large-format wall sculpture. The galvanized finish provides a reflective industrial texture; combine with backlighting, painted accents, or patinas for gallery-style pieces.

Garden Trellis/Arbor Connector Kit

Use the plates to join cedar or pressure-treated posts for small arbors, pergolas, and trellises. The pronged plates make fast, split-resistant connections ideal for DIY garden structures. Combine with pre-cut lumber plans so hobbyists can build a sturdy garden piece in an afternoon.

Heavy-Duty Wall Hook & Pot Rack

Embed a truss plate into a hardwood board and add custom hooks or a steel rod to create a heavy-duty coat rack, pot rack, or bicycle hanger. The plate provides the bite into the wood and a design accent, allowing the rack to carry more weight than conventional hanging hardware.