Features

- -Stainless Steel 316 Bar Foot Rest Rail Tubing ;

- -Popular choice for bar foot rail installation;

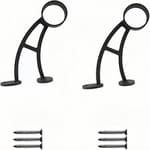

- -One arm of the bracket screws directly into the face of your bar while the other arm rests on the floor;

- -Two points of contact provide the best support and stability;

- -Fits 2" outside diameter bar rail tubing;

Specifications

| Color | Matte Black |

| Release Date | 2024-10-01T07:00:00Z |

| Size | 2 Pack |

| Unit Count | 2 |

Related Tools

Combination bar-and-floor foot rail bracket constructed from 316 stainless steel to fit 2" (50.8 mm) outside-diameter foot rail tubing. One arm fastens to the bar face while the other rests on the floor for two-point support and stability; screws are included for installation, the finish is matte black, and the pack contains two brackets.

HAIWEN Stainless Steel Bar & Floor Mount Combination Foot Rail Bracket ,Fits 50.8mm/2inch OD Bar Foot Rail Tubing Furniture Hardware with Screws Review

Why I chose this combo bracket

I added a foot rail to a home bar this year and went looking for hardware that was sturdy, straightforward to install, and visually understated. The HAIWEN combo foot rail bracket checked the right boxes on paper: 316 stainless construction, a matte black finish that would disappear against a dark bar face, and a design that ties the rail both to the face of the bar and the floor. I paired it with 2-inch OD stainless tubing and used a two-pack to start a short run before ordering more.

What follows is my experience installing and living with these brackets, along with the practical details I wish I’d known before I started drilling.

Build and finish

The overall build quality is solid. The bracket feels dense, with no tinny ring or flex when you load it by hand. Edges are clean and consistent, and the finish is an even matte black with a very slight sheen—enough to resist showing dust and fingerprints, but not so glossy that it reads “industrial.” The finish held up well through installation; I taped off the contact points and was not gentle, and I didn’t pick up any scratches or chips.

The 316 stainless specification is meaningful if you’re near moisture, in a kitchen, or considering an outdoor application. It’s more corrosion-resistant than common 304 stainless. Finish aside, the base material gives peace of mind if a spill goes unnoticed or you mop right up to the bracket regularly.

How it installs

This is a combination bracket: one arm screws into the face of the bar, and a lower arm rests on the floor. The two-point support is what sold me—it substantially reduces wobble compared with face-only brackets, and it spreads load into the floor rather than relying entirely on fasteners biting into the bar face.

A few practical notes from my install:

Hardware: Screws are included. For my setup (3/4-inch hardwood face over solid blocking), I used the included screws for a test fit, then swapped to longer stainless fasteners for the final installation. If your bar face is MDF or thin veneer, add blocking or a backer board; don’t count on short screws alone.

Floor contact: The lower arm simply bears on the floor—it’s not an anchor point. On finished hardwood, I added a thin, inconspicuous neoprene pad to prevent scuffing and to eliminate any potential buzz or micro-movement under load.

Layout: I set brackets at 4-foot spacing and one near each end. That’s a conservative spacing that felt rock solid with 2-inch tubing. If your rail will see heavier use, tighten the spacing.

Protect the finish: Painter’s tape wherever I expected tool contact was worth the extra minute.

Leveling: Dry-fit the rail into two brackets on the floor, mark centers, then transfer those marks up to the bar face with a laser or long level. It keeps the run perfectly straight and avoids creeping errors.

Real-world dimensions and ergonomics

Specs that matter here are the fitment and the working height. The bracket is designed for 2-inch (50.8 mm) outside-diameter tubing. Tubes slid in snugly without play, and set screws (on my rail ends) seated cleanly.

On height, my tape measure read roughly 6 inches from the floor to the centerline of the rail when the bracket is seated. Projection from the bar face to the rail center was also about 6 inches on my install. That geometry produced a comfortable resting posture: toes land on the rail naturally, and calves don’t crowd the bar face.

If you prefer a higher footrest or have a use case that demands more elevation, this fixed-height design isn’t adjustable. In that case, you’d want a different bracket pattern that sets the rail center higher. For most residential bars and kitchen islands, though, the roughly 6-inch height felt right and matched common ergonomic guidance.

Stability and feel underfoot

With the rail mounted, the combo design shows its value. The floor contact reduces the lever arm on the screws into the bar face, so there’s less tendency for the bracket to flex or “smile” under load. In day-to-day use—resting feet, occasional leaning while chatting—there’s no creak, shift, or perceptible spring. I intentionally loaded a single bracket area while testing the spacing layout; the rail deflected minimally and returned without complaint.

Note that because the floor arm isn’t anchored, the ultimate stability still depends on the integrity of the fasteners into the bar and the rigidity of the bar structure. If you’re installing on a thin face panel or a hollow chase, invest the time to add blocking.

Design and compatibility

Finish: Matte black pairs well with modern and transitional bars. It reads as intentional hardware, not an afterthought, and hides scuffs better than mirror finishes.

Material: 316 stainless is appropriate for damp basements, kitchens, and even covered outdoor spaces. If installing outdoors, keep in mind that the black finish will get warmer in direct sun and will age differently from bare stainless.

Tubing: This is a 2-inch OD solution. If you’re migrating from a smaller legacy rail (1.5-inch, for example), you’ll need new tubing to match.

Pack size: The two-pack makes sense for short runs, but plan your bracket count ahead of time. A typical 8–10 foot run will need three or four brackets, plus end caps and elbow fittings if you’re turning corners (not included).

What I’d improve

No product is perfect, and a few tweaks would make installation foolproof:

Clear dimensioning: A simple diagram with centerline height and projection would help plan installs without guesswork. I measured about 6 inches for both, which is fine, but it’s the number I want to see before buying.

Optional floor pad: Including a thin neoprene or felt pad for the floor contact would prevent scuffing and make the “resting” interface feel more deliberate.

Hardware clarity: The included screws work, but guidance on screw length for typical substrates (solid wood, plywood with blocking, etc.) would save a trip to the hardware store.

Maintenance and durability

Cleanup has been easy. A microfiber cloth and mild soap takes care of the occasional shoe scuff on the rail and bracket. The matte finish hides minor marks, and the 316 stainless underlayer inspires confidence against corrosion. If you use aggressive cleaners on the floor, avoid soaking the interface; wipe it dry to protect the finish over the long term.

After living with the setup, I haven’t seen any finish failure, flaking, or color change. The rail still sits square, and fasteners haven’t loosened.

Who it’s best for

Home bars and kitchen islands that need a clean, understated bracket in black.

Installations where a two-point support reduces wobble without drilling into the floor.

Users who already have or want 2-inch OD tubing and want a robust, corrosion-resistant bracket.

I’d look at a different bracket if you need a taller rail position, want a floor-anchored base for commercial abuse, or are married to a different tube diameter.

The bottom line

The HAIWEN combo foot rail bracket does the fundamentals right: solid 316 stainless construction, a durable matte black finish, and a design that meaningfully improves stability by sharing the load with the floor. Installation was straightforward with a few common-sense precautions—solid blocking behind the bar face, careful layout, and a protective pad under the floor contact. Once installed, the rail feels secure and comfortable, with a working height that suits most residential setups.

Recommendation: I recommend this bracket for residential bars and kitchen islands that use 2-inch OD rail and want a stable, low-visibility support in matte black. It’s an especially good choice if you prefer not to drill into the floor but still want the steadiness of a two-point design. If you need a higher rail centerline or heavy-duty floor anchoring for commercial traffic, choose a different bracket style tailored to those requirements.

Project Ideas

Business

Custom Bar Build Service

Offer a niche service building and installing stainless 2" foot rails for residential and commercial bars. Market the two-point bracket system as a premium stability upgrade for high-traffic venues and patios. Upsell powder-coating or matte-black matching to client decor and provide installation + warranty packages.

DIY Kit Product Line

Package the brackets with pre-cut 2" tubing, end caps, mounting screws, and a step-by-step guide to sell as a DIY footrail kit online. Create multiple kit sizes (single run, corner sets, and full bar kits) and offer instructional videos. Target DIY home-bar builders, restaurateurs, and event rental companies.

Hospitality Retrofit Contracts

Pitch to bars, hotels, and restaurants to retrofit existing bars with stainless foot rails that anchor to both face and floor for safety and durability. Position the offering as a low-cost renovation that improves customer comfort and reduces maintenance—bundle installation, periodic inspection, and corrosion-resistant materials for recurring revenue.

Workshops & Maker Classes

Run hands-on workshops teaching attendees how to plan, cut, and install bar-foot rails using the combination brackets. Charge per-person workshop fees and sell take-home kits. This builds community awareness of your brand and generates product sales plus potential referrals for custom work.

Wholesale Supply for Builders

Become a supplier of 316 stainless combination brackets and matching tubing to boutique cabinetmakers, commercial fit-out contractors, and furniture builders. Offer volume discounts, custom branding (matte-black finish control), and quick-ship kits so trade customers can finish projects faster and to a higher standard of stability.

Creative

Home Bar Foot Rail Upgrade

Install a matte-black 2" foot rail along a home or garage bar using the combination face-and-floor brackets for two-point stability. Use the included screws and 316 stainless brackets to mount 2" OD tubing so the rail withstands heavy use and moisture—ideal for open-air patios or basement bars. Add rubber end caps and LED strip behind the rail for a polished, comfortable foot rest.

Custom Standing Desk Footrail

Attach a horizontal 2" tube beneath a standing desk or high workbench to create a sturdy footrest. The floor-anchoring arm of the bracket prevents wobble even with lateral pressure—use the matte-black finish for a modern industrial look. This gives makers and remote workers a comfortable perch and reduces leg fatigue.

Industrial Towel & Blanket Rack

Build a wall-mounted towel or blanket rack using multiple lengths of 2" tubing and the combination brackets. Install one arm to the wall or cabinet face and let the other rest on the floor for extra load-bearing capacity—perfect for heavy throws or a stack of towels in a bath or mudroom. The 316 stainless brackets resist corrosion in humid environments.

Pet Feeding Nook Rail

Create an elevated pet feeding station with a horizontal rail in front to keep bowls from sliding away. The floor-supporting bracket helps the rail take knocks from energetic pets. Matte-black hardware blends into modern interiors while the stainless construction holds up to spills and easy cleaning.

Modular Low Partition with Kick Rail

Use 2" tubing and the two-point brackets to make low room dividers for cafes or studios that double as foot rails at the base. The floor-mounted arm prevents tipping when people lean on the divider and lets you create modular runs that are easy to reconfigure—great for pop-up markets or maker spaces.