Features

- -Stainless Steel 304 Bar Foot Rest Rail Tubing ;

- -Popular choice for bar foot rail installation;

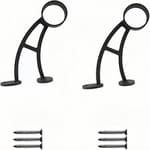

- -One arm of the bracket screws directly into the face of your bar while the other arm rests on the floor;

- -Two points of contact provide the best support and stability;

- -Fits 2" outside diameter bar rail tubing;

Specifications

| Color | Sliver |

| Release Date | 2024-10-01T07:00:00Z |

| Size | 2 Pack |

| Unit Count | 2 |

Related Tools

Stainless steel 304 combination bar-and-floor mounting brackets designed to support 50.8 mm (2") outside-diameter foot rail tubing. One arm fastens to the face of the bar while the other rests on the floor for two-point stability; includes screws and is supplied as a two-pack.

HAIWEN 2Pack Stainless Steel Bar & Floor Mount Combination Foot Rail Bracket ,Fits 50.8mm/2inch OD Bar Foot Rail Tubing Furniture Hardware with Screws Review

Why I chose these combination brackets

I installed these combination brackets on a home bar this summer, and they surprised me in a few ways—mostly good. I wanted a clean, sturdy foot rail that wouldn’t wobble over time, and I specifically looked for a bracket that ties into both the bar face and the floor. The HAIWEN combination foot-rail brackets tick that box: one arm screws into the bar, the other anchors to the floor, creating a rigid triangle that resists both downward load and lateral torque from restless feet.

These brackets are designed for 2-inch outside-diameter tubing (50.8 mm), which is the most common size for bar foot rails and a comfortable diameter underfoot. The set ships as a two-pack with mounting screws included.

Build quality and finish

The brackets are 304 stainless steel, which is the right choice for an indoor bar or any space with occasional moisture. The finish on my set was a bright, reflective “silver” (spelled “sliver” on the listing), with even polishing across the visible surfaces. Edges were clean, and the welds were ground and blended well enough that they disappear in casual use. This isn’t mirror-finish boutique hardware, but it looks crisp and professional installed.

Because they’re 304 stainless, they shrug off shoe scuffs and the odd splash from mopping without spotting, provided you wipe them down. If you’re planning a coastal installation or an outdoor bar, 316 stainless would be the safer call, but for indoor residential or hospitality use, 304 is the practical sweet spot.

The two-point mount makes a difference

Compared to wall-only brackets, the bar-and-floor combination layout really does add stability. With the rail supported at two points, the setup feels notably rigid underfoot. There’s less “racking” when someone plants a heel and twists, and less movement when multiple people rest on the rail at once. On my install, the rail stayed level and silent, with no creaks or loosening after a few weeks of regular use.

If your bar face isn’t particularly stout—think thin veneer over MDF—this bracket style also spreads the load. You still want solid blocking behind the face (more on that below), but you’re not relying solely on screws into a vertical surface to resist downward force.

Real-world sizing and the height you’ll actually get

A critical point: these brackets position a 2-inch OD rail at roughly 6 inches off the finished floor (measured to the centerline of the tube, it’s closer to 5 inches). That’s the conventional height for a foot rail and, ergonomically, it feels right. If you’re expecting an 8–12 inch elevation for some reason—say, a knee rail or a handhold—that’s not what these are designed for.

Depth from the bar face to the rail centerline is also around 6 inches, which provides comfortable toe clearance without pushing the rail too far into walk space. In other words, the geometry is exactly what you want for a traditional bar footrest.

My advice: confirm these dimensions against your bar overhang and toe-kick, and mock up the rail with painter’s tape before drilling. If you need a taller or shorter rail height, choose a different bracket pattern; the geometry on this one isn’t adjustable.

Installation experience

Planning and spacing: For a 2-inch tube, I aim for a bracket every 4 feet or so. The two-pack is perfect for a short run, but you’ll likely need additional brackets for anything longer. Dry-fit your tubing and mark bracket positions with a level before committing to holes.

Bar-face anchoring: If your bar face is decorative only, add blocking or hit studs. I used stainless wood screws into a solid frame through pre-drilled, countersunk holes. The kit includes screws, which are fine for wood, but I preferred my own screws for length and thread quality. Pre-drill to avoid splitting, and hit the same vertical plane for every bracket to keep the rail straight.

Floor anchoring: On wood floors, use stainless screws long enough to bite into subfloor. For tile over concrete, use appropriate masonry or sleeve anchors and take your time drilling—chips at this stage ruin aesthetics quickly. I set a thin neoprene gasket under the floor flange to protect the finish and absorb minor irregularities.

Level and alignment: With combination brackets, leveling becomes easy: tighten the face screws lightly, level the bracket arm, then mark floor holes. Once the floor anchors are in, you can snug everything down and drop the tube into the saddles.

The whole process, with careful measuring and drilling through porcelain tile, took me about two hours for a single 7-foot run using three brackets.

Stability and everyday use

The finished rail feels secure. The two-point contact makes a noticeable difference in how “solid” the rail feels when someone leans or swivels their foot. There’s no springiness, and the brackets don’t deflect under a typical bar’s use. The 2-inch tube diameter is comfortable, distributing pressure across the shoe sole without creating a pressure point.

Noise is often overlooked; cheaper single-point brackets can squeak as the face screws work in and out with lateral load. I haven’t heard a sound from these. After installation, a quick check with a hex driver two weeks later showed no loosening.

Compatibility and fit

Tubing: The saddles are shaped for 2-inch OD tubing. If you’re using 1.5-inch or 1.75-inch tube, pick a different bracket model; this one won’t cradle smaller sizes neatly.

Environment: Indoors and away from salt air, 304 stainless is appropriate. For commercial back bars that see aggressive cleaning chemicals, rinse and dry if chlorinated cleaners are used to preserve the finish.

Surfaces: The included screws make sense for wood. For concrete or tile, budget for proper anchors. If you’re unsure, a local fastener supplier can match anchors to your subfloor for a few dollars, which is money well spent.

Maintenance

Maintenance is simple: a damp cloth and mild soap, then dry with a microfiber towel. Avoid steel wool or harsh scouring pads; they’ll mar the finish and can embed carbon steel that later causes tea staining. If scuffs appear, a fine non-woven pad used lightly, with the grain, will blend them out.

What I’d improve

Two things stood out:

Hardware breadth: It would be helpful if the kit included a mixed hardware pack—wood screws, plus anchors for concrete. Most installations will require a trip to the hardware store if you’re not mounting to wood.

Documentation and dimensional clarity: A simple dimension diagram in the box would reduce guesswork. The brackets put the rail around 6 inches off the floor; spelling that out clearly would help users verify fit before drilling.

None of these are dealbreakers, but they’re worth noting so you can plan accordingly.

Value

As a two-bracket set in 304 stainless, these land in the reasonable-value category. The finish is good, the geometry is correct, and the two-point support delivers real-world stability you can feel. If you need a longer run, factor in the cost of an extra bracket or two and proper anchors. Given the durability and the clean look, I consider them a smart buy for residential bars and many light commercial installs.

Recommendation

I recommend these combination foot-rail brackets for anyone installing a 2-inch OD bar footrest on a standard-height bar and looking for a solid, stable feel underfoot. They’re well-made in 304 stainless, the two-point mount keeps the rail rigid, and the finish looks right in both modern and traditional spaces. Just be sure the ~6-inch rail height fits your design, plan your spacing (typically every 4 feet), and source the right anchors for your floor. If you need an adjustable height, a different rail diameter, or outdoor/marine-grade corrosion resistance, look elsewhere; otherwise, these brackets are a dependable, straightforward choice.

Project Ideas

Business

Mobile Bar Installation Service

Offer on-site installation of professional foot rails for homeowners and small hospitality venues. Package the stainless steel brackets with pre-bent 2-inch tubing, end caps, and optional LED lighting as an add-on. Market to new-build contractors, Airbnb hosts, and homeowners renovating basements or outdoor kitchens.

Custom Restaurant & Bar Fit-Outs

Specialize in commercial fit-outs focused on seating comfort and durability. Use the two-point brackets to build heavy-duty foot rails for bars, booths, and high-top tables. Offer customization in tube finish, bracket finish, and integrated accessories (rubber grips, branded end caps). Provide bulk pricing and maintenance contracts for venues.

DIY Footrail Kits

Create and sell do-it-yourself kits that include the stainless 2-pack brackets, pre-cut 2-inch tubing segments, screws, caps, and a simple template for installation. Offer kit variations (indoor, outdoor, LED-ready) and sell them through an online store or marketplaces. Include video tutorials and upsell matching hardware and finishes.

Retail Fixture & Display Supplier

Use the brackets to build modular display rails and shoe racks for boutique stores. The floor-mounted support lets you create long-span rails without sagging, ideal for footwear displays or garment racks. Sell complete fixtures or custom-sized runs to retailers and visual merchandisers.

Event & Pop-Up Bar Rentals

Launch a rental fleet of portable bar footrail systems for events, trade shows, and pop-up bars. The two-point brackets provide stability on varied flooring, and systems can be designed for quick assembly and teardown. Market packages by event size and offer add-ons like branded end caps, lighting, and transport cases.

Creative

Home Bar Makeover

Use the stainless steel 304 combination brackets and 2-inch OD tubing to add a professional foot rail to a home bar or island. Mount the brackets to the face of the bar and run a polished or powder-coated 2-inch tube through them. Add rubber end caps and integrated LED tape underneath the rail for ambient lighting. The two-point bracket gives strong support for heavy use and creates a finished, commercial look in a residential space.

Convertible Kitchen Island Footrest

Create a removable footrest for a kitchen island that doubles as a low-hanging towel or magazine rail. Use the floor-mounting arm for extra stability when in use and design quick-release clamps so the rail can be detached for cleaning or to open up floor space. Use brushed or matte stainless tubing to match modern kitchen hardware.

Outdoor Patio Lounge Rail

Build a weatherproof foot rail system for outdoor seating areas (covered patios, pergolas) using 304 stainless parts. Incorporate a slightly elevated mounting plate to avoid pooling water on the bracket, and pair with marine-grade tubing. Add non-slip rubber sleeves where feet rest and/or fit a hidden LED strip along the underside of the rail for night ambiance.

Industrial Shower & Towel Rail

Repurpose the brackets to create an industrial-style towel and robe rail for a bathroom or locker room. Mount 2-inch stainless tubing at varying heights for hand towels, bath towels, and robes. The floor support arm prevents sagging under heavy wet towels, and the 304 stainless finish is ideal for humid environments.

Raised Pet Feeding Station

Design a raised feeding station for pets with a continuous 2-inch rail that stabilizes an elevated platform for bowls. The brackets act as sturdy legs and foot stabilization points so the station remains steady while pets eat. Use removable brackets to disassemble the station for cleaning or transport.