Features

- Cuts right-hand external threads

- Heat-treated high-carbon steel construction

- Rust- and tarnish-resistant finish

- Laser-etched size and starting-side markings

- Precision machining for a consistent fit

- Flute design to aid chip clearance

Specifications

| Part Number | BPD14F18 |

| Size And Thread | 1/4 - 18 |

| Standard | NPT |

| Thickness | 0.433 in |

| Pack Quantity | 1 |

| Material | High-carbon steel |

| Color / Finish | Metal, rust- and tarnish-resistant |

| Warranty | 1 Yr |

| Product Dimensions | 0.39 in x 1.81 in x 5.88 in |

| Weight | 0.07 lb |

| Upc | 000346621488 |

Related Tools

Related Articles

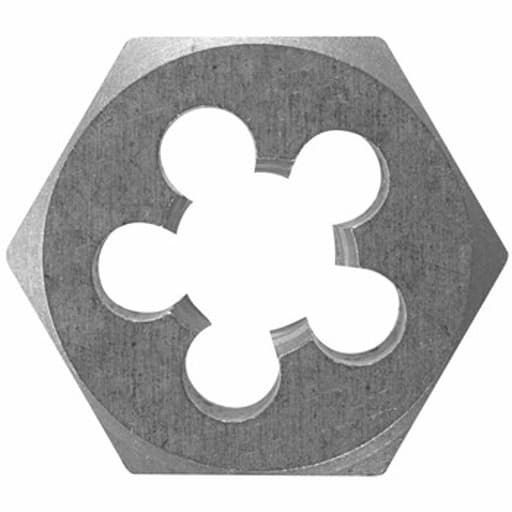

Hand die for cutting right-hand external NPT threads on rods, bolts, and studs. Made from heat-treated high-carbon steel with a rust- and tarnish-resistant finish. Features laser-etched size/start markings, precision machining for fit, and flute geometry for chip clearance.

Bosch 1/4 in - 18 NPT High-Carbon Steel Pipe Die Review

Why I reached for the Bosch 1/4-18 NPT die

I ran into a small but nagging problem: I needed a clean 1/4-18 NPT male thread on a short stub to mate with an existing fitting. I didn’t need a full pipe-threading setup—just a reliable hand die that would track straight, cut predictably, and leave a sealable taper. That’s how I ended up testing the Bosch 1/4-18 NPT die (model BPD14F18). After several sessions on mild steel and brass stock, plus a quick pass on a piece of black iron pipe, I’ve got a clear sense of where it shines and where it’s just okay.

Build and design

This die is heat-treated high-carbon steel with a rust- and tarnish-resistant finish. It’s a compact, standard-profile round die with a 0.433-inch thickness and a weight of about 0.07 pounds—light and easy to handle. The laser-etched markings are genuinely useful; the size and the starting-side marking are crisp and easy to read, even after an oily afternoon. The flutes are generous enough to carry chips out without packing immediately, and the overall machining looks clean—no burrs in the teeth or rough transitions in the gullets.

The die is right-hand only, as most are, and it’s cut to NPT, not NPS. That taper makes alignment and pressure control more important than with straight threads, but it also means you can quickly tune the final fit by running the die a little more or a little less.

Setup and compatibility

I used the die in a standard die stock and also in a small adjustable die holder on a tap wrench for tight spots. It seats well and tracks true if you take your time on the start. The starting-side etch prevents that moment of second-guessing, and the outside diameter is a conventional size that fits typical die stocks without fuss.

Because this is high-carbon steel rather than high-speed steel, I kept my expectations realistic for harder alloys. It excelled on mild steel, brass, and aluminum. On tougher steels, I slowed down, used plenty of cutting oil, and made sure to back off every quarter turn to break chips—and it did the job, but I wouldn’t choose it for a week of production threading on stainless.

In-use performance

The die bites predictably once you’ve chamfered the workpiece. I always recommend a pronounced chamfer on NPT starts—about 30–45 degrees—to help center the die and reduce the initial load on the cutting edges. With a good cutting oil, the first revolution feels steady rather than grabby. From there, the cutting action is smooth, with clear chip formation and decent evacuation through the flutes.

One detail I appreciated is how consistent the die feels across the taper. Some budget dies can act loose, then suddenly grab as the taper deepens. This one transitions evenly, making it easier to hit the engagement depth you want. Threading up to a test fitting in stages gave me a snug, sealable fit without Teflon tape on the first pass; with tape or compound, it sealed well under typical shop air pressures.

Accuracy and thread quality

The threads are crisp, clean, and appropriately tapered. Crest and root formation look uniform, and I didn’t see the ragged edges you sometimes get from dull or poorly ground dies. Gauging with a few different 1/4-18 NPT female fittings, the fit was in the pocket. I typically stop short, test fit, then advance a quarter turn at a time until I have the engagement I want. This die responded predictably to that approach.

On softer materials like brass, surface finish was excellent. On mild steel, finish quality remained good and consistent; a light deburr on the lead-in was all I needed. I wouldn’t call it glass-smooth on harder stock, but it was clean enough that sealing performance wasn’t impacted.

Durability and maintenance

I ran a modest batch of parts—enough to get a feel for wear—and the cutting edges held up well. High-carbon steel won’t outlast HSS in abusive conditions, but for shop work and field fixes it’s perfectly serviceable, especially if you use cutting oil and avoid overheating the die. The rust-resistant finish actually does something: after sitting with residue from sulfur-based oil for a few days, it wiped clean without discoloration or flash rust.

A few maintenance tips helped longevity:

- Brush out chips frequently; don’t let packed chips recut.

- Use a proper cutting oil, not general-purpose lubricant.

- Back off regularly to break chips and reduce torque.

- Wipe down after use and add a light film of oil before storage.

Limitations

A couple of practical constraints are worth noting:

- High-carbon steel construction means it’s not the best pick for repeated work in stainless or hardened steels. It will cut, but you’ll accelerate wear.

- It’s a fixed die with no split for adjustment. For most NPT work, that’s fine, but you won’t be dialing in fit with set screws like you can on some adjustable dies.

- NPT threading demands a good chamfer and careful depth control. This die is accurate, but if you’re new to NPT, plan to test fit frequently until you internalize how many turns equal the engagement you want.

None of these are dealbreakers; they’re more about matching the tool to the task.

Tips for best results

If you’re new to cutting external NPT threads by hand, a few habits make a big difference:

- Prep the work: Turn the OD to the recommended starting diameter and add a generous chamfer.

- Align carefully: Use the etched “start” side, apply steady axial pressure for the first full turn, and check squareness from two angles.

- Use the right oil: A sulfurized cutting oil keeps temperatures down and improves surface finish.

- Cut in stages: Quarter-turn forward, a touch back to break chips, then continue.

- Fit as you go: Stop early, test a female fitting, then advance incrementally to fine-tune seal engagement.

- Finish clean: Deburr lightly and clean the threads before applying tape or compound.

Alternatives and value

Compared to pricier HSS dies, this Bosch option slots in as a practical, budget-friendly shop staple. If you’re threading stainless day in and day out, I’d steer you toward HSS or even a die head on a threading machine. But for maintenance techs, hobbyists, HVAC installers, or general fabricators who occasionally need a precise 1/4-18 NPT male thread, this die hits a sweet spot between cost and performance.

The one-year warranty is standard for a hand die and adds a little peace of mind. Between the clean machining, readable markings, and reliable cutting action, it feels like a thoughtful design rather than a generic rebrand.

The bottom line

The Bosch 1/4-18 NPT die delivers consistent, accurate threads with an easy start and predictable taper engagement. The laser-etched markings and chip-clearing flutes are small touches that add up in daily use. Its high-carbon steel construction is well heat-treated and finished, and while it won’t replace HSS for abusive workloads, it holds its own in the materials most of us thread by hand.

Recommendation: I recommend this die for anyone who needs a dependable 1/4-18 NPT solution for mild steel, brass, aluminum, and occasional use on tougher steels with proper technique. If you’re a production shop cutting stainless all week, look elsewhere for HSS. But for maintenance, repair, and small-batch fabrication, this Bosch die is a tidy, reliable tool that earns its spot in the die drawer.

Project Ideas

Business

On-Demand 1/4" NPT Threading Service

Offer a local/mobile service to cut or chase 1/4" NPT external threads on customer-supplied rods and studs for pneumatics, gauges, and instrumentation projects. Market to makerspaces, auto/wood shops, and hobby robotics. The heat-treated die and clear start markings support quick, repeatable results with minimal rework.

Mini Industrial Desk Organizer Line

Design and sell compact organizers built from 1/4" NPT crosses/tees and custom pre-threaded rods: pen cups, phone stands, business card holders. Provide multiple finishes (raw, matte black, brass). The precision die ensures clean threads so kits assemble smoothly for customers.

Terrarium/Reptile Misting Hardware Kits

Sell ready-to-assemble misting arches, nozzle mounts, and bulkhead pass-throughs using standardized 1/4" NPT connections and pre-threaded rods. Bundle with adapters, mounting plates, and sealant tape. Position as an upgrade kit compatible with popular pumps and nozzles.

Workbench Air Manifold Bars

Produce bench-mounted air distribution manifolds with multiple 1/4" NPT ports, plus pre-threaded standoffs/rods for easy installation under shelves or along pegboards. Offer options with quick couplers and gauges. Clean die-cut external threads reduce leak points and returns.

Gauge Trees for Home Labs

Assemble modular gauge trees for homebrew, vacuum experiments, and shop compressors using 1/4" NPT tees/crosses and custom threaded rods. Offer configurations with isolation valves, test points, and mounting brackets. Sell direct online with made-to-order layouts.

Creative

Industrial Mini Plant Hangers

Cut 1/4" NPT male threads on the ends of short steel or brass rods and screw them into 1/4" NPT elbows/tees to create minimalist wall-mounted plant hooks for air plants or tiny succulents. Use the die’s laser-etched start-side to avoid misstarts and the chip-clearing flutes to keep threads crisp. Finish the assembly with blackened, brushed, or clear-coated metal for an industrial aesthetic.

Desk Airbrush Stand + Air Manifold

Make a compact base that holds a 1/4" NPT cross. Thread small rods with 1/4" NPT and mount them as hooks/cradles for airbrushes. Add 1/4" NPT-to-1/8" adapters on the ports for multiple airbrush hoses, and include a small pressure gauge (common 1/4" NPT) on one port. The die’s precision fit helps ensure leak-ready male threads when used with tape or paste.

Terrarium Misting Arch

Thread both ends of a gently bent aluminum rod to 1/4" NPT and mount it through the terrarium lid using 1/4" NPT bulkhead fittings. Attach misting nozzles via standard 1/4" NPT adapters along the arch. The high-carbon steel die will cut consistent tapered threads so fittings seal properly with thread sealant.

Gauge-Cluster Clock Sculpture

Collect a few vintage pressure/vacuum gauges with 1/4" NPT female ports. Thread rods to 1/4" NPT to mount them onto a hardwood base via tees/crosses, and swap one gauge face for a small clock insert. The industrial cluster becomes a functional desk clock with a steampunk vibe.

Modular Drip Irrigation Ring

Create a small irrigation halo for potted plants from curved rod sections with 1/4" NPT threads at each joint. Connect with 1/4" NPT elbows and 1/4" NPT-to-barb adapters for tubing and emitters. The die’s tapered profile helps make reliable male ends that seat and seal with common fittings.