Features

- Break-resistant construction

- Welded bi-metal design with sharp steel cutting edge and high-strength body

Specifications

| Number Of Pieces | 5 |

| Product Pack Quantity | 5 |

| Includes | (1) Pack of (5) Utility Blades |

| Product Application | Cutting |

| Primary Material | Metal (bi-metal construction) |

| Product Height | 5.875 in |

| Product Length | 0.219 in |

| Product Width | 1.875 in |

| Product Weight | 0.052 lb |

| Country Of Origin | United States |

| Upc | 76174110074 |

| Warranty | Lifetime Limited Warranty |

Related Tools

Related Articles

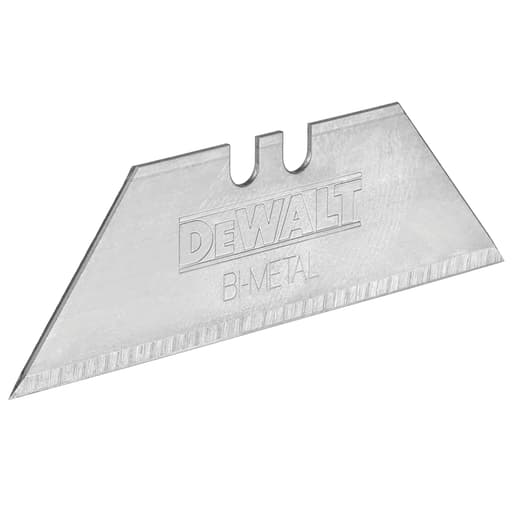

Pack of five bi-metal utility blades with a welded sharp steel cutting edge and a high‑strength body designed to resist breakage during cutting tasks.

DeWalt High Strength Bi-Metal Utility Blade (5 PK) Review

Why these blades earned a spot in my kit

I go through a lot of utility blades—breaking down double-wall boxes, trimming drywall, slicing carpet, and scoring vinyl and plastic. After several weeks rotating these DeWalt bi-metal blades through my everyday knives, I’ve got a clear picture of where they shine, where they stumble, and whether they’re worth reaching for over the big-box generics.

Build and design

These are standard-size utility blades with a welded bi‑metal construction: a high-strength, flexible body mated to a harder, sharp cutting edge. That pairing is the point. The harder edge resists dulling, while the more forgiving body helps prevent catastrophic snaps when you twist a bit mid-cut. In practice, the design does exactly that. The edge feels keen out of the pack—clean grind, no visible waviness—and the spine shows a touch more resilience than typical carbon steel disposables.

They’re sold in a five-pack. That’s convenient for slipping into a pouch or glovebox, though it’s on the small side if you’re outfitting a crew or a job that eats blades. For solo work or a service truck, the pack size works.

An extra confidence marker: they’re made in the USA and carry a lifetime limited warranty. You’ll almost never warranty a consumable blade, but it still signals that defects shouldn’t be part of the experience.

Performance in common materials

I tested the blades across the usual suspects—corrugated, drywall, carpet, roofing membrane, landscape fabric, and some rigid foam. Here’s how they behaved.

Cardboard and packaging: The edge stays crisp for a good run of double-wall cuts. I could break down a pallet’s worth of cartons without flipping or replacing. On plastic strapping and heavy shrink film, the edge slices rather than snags, which is always the sign of a clean grind.

Drywall: Scoring gypsum is a great way to find the line between sharp and durable. These blades cut cleanly on the first score and remained predictable after a dozen sheets. The bi-metal body helps when you accidentally twist the knife while snapping a sheet—you feel a little flex rather than a snap. I still avoid twisting any blade, but this design buys you margin.

Carpet and vinyl: On carpet, the edge retention is noticeable. I got longer runs between flips compared to standard carbon blades. Vinyl plank scoring was smooth, with less of that “skitter” you feel when a blade starts to dull. No chipping at the edge, even after several planks.

Roofing and exterior membrane: Cutting synthetic underlayment and ice-and-water shield tends to gum edges. These blades stuck with it better than average; the edge loaded up with adhesive at about the usual pace, but cleaned easily and returned to form.

Plastics and foam: Rigid foam, PVC trim, and poly sheeting all cut predictably. No chatter, no tendency to wander off line when you’re pulling a long score.

Edge life inevitably depends on the material and the hand behind the knife, but I consistently got more cuts per face than with basic carbon steel blades. I’d ballpark the advantage at roughly one-and-a-half times, sometimes closer to double in clean material. That’s enough to make a difference over a long day.

Durability and safety

The promise of “break-resistant construction” isn’t marketing fluff here. I deliberately abused one blade during a demolition day—prying up old caulk and scoring next to masonry. The tip deformed slightly before the blade would even think about snapping, which is exactly what I want. The spine and notches held up without mushrooming.

A few notes for safe handling:

- Treat the cutting edge as you would any premium blade: it’s sharp out of the pack and will surprise you if you get casual.

- Because the body flexes a bit more than some heavy-duty carbon blades, you’ll feel that in aggressive pull cuts. It’s not a negative, just a slightly different feedback that quickly becomes familiar.

I didn’t find burrs on the spine or the notches. Everything seated cleanly in my knives and operated smoothly.

Compatibility and fit

I used these blades in a mix of fixed, folding, and retractable knives from several brands. No fit issues. The notches are cut accurately, so the slider engagement is positive with distinct stop points. In knives with internal storage, the five-pack gave me a full reload with a couple spares in the pouch.

One small observation: in a very tight new knife, the fresh blade felt a hair snug during the first few cycles, then ran normally. That’s more about the knife than the blade, but worth noting if your knife is brand new or has tight tolerances.

Packaging and value

The five-pack packaging is compact and pocketable. It isn’t fussy, but you’ll still want a pair of scissors or a knife to open it safely—no frustration, just standard retail plastic. The holder keeps the remaining blades from rattling loose.

Value-wise, bi-metal blades cost more per piece than basic carbon steel. In return, you’re getting longer edge life, better resistance to snap under torsion, and more predictable performance across tough materials. If you cycle blades constantly on demolition, that cost difference may be a wash. But for general construction, shop work, facilities maintenance, delivery breakdown, or any task where you prize consistency, these pay back in fewer swaps and cleaner cuts.

Quirks and limitations

- Pack size: Five blades won’t last long on a jobsite. If you’re outfitting multiple folks, look for larger quantities. For a single tech or DIY kit, five is fine.

- Not a pry bar: The more resilient body can tempt you to push your luck. It’s still a razor edge on a thin blank. Use it for cutting; reach for a scraper or pry tool when that’s the job.

- Edge coating: There’s no exotic coating here, and none is needed. Keep the blades dry and wipe off adhesive build-up to maximize life.

Who will appreciate these blades

- Tradespeople cutting drywall, carpet, roofing membranes, and packaging who want fewer blade changes and less chance of snap under torque.

- Shop and warehouse crews who need predictable, clean cuts without feathering or tearing material.

- DIYers who prefer buying a smaller pack of better blades rather than a big box of disposables.

The bottom line

These DeWalt bi‑metal blades strike a practical balance: a hard edge that stays keen, bonded to a tough body that shrugs off the minor abuse utility blades inevitably see. They fit every knife I tried, cut cleanly across a wide spread of materials, and resisted snapping when I made less-than-ideal cuts. You can absolutely get by with cheaper carbon blades, but if you value longer edge life and a little extra safety margin, these are a noticeable step up.

Recommendation: I recommend these blades. They’re a reliable, made‑in‑USA option with real improvements in edge retention and break resistance, backed by a lifetime limited warranty. If you burn through blades daily on heavy demo, you may want a larger pack size. For most users—from pros to serious DIYers—the performance and consistency justify the upgrade.

Project Ideas

Business

Custom Stencil Shop

Offer made-to-order Mylar stencils for cafes, parking lots, craft boutiques, and wall artists. Use the break-resistant blades for fast, accurate cutting of intricate logos and lettering, and sell via Etsy/local pickup with tiered pricing.

Leather Goods Micro‑Brand

Launch a small line of wallets, key fobs, and cord organizers. Precision cutting with bi-metal blades ensures consistent parts and clean edges, reducing sanding time and elevating perceived quality. Sell at markets and online.

Display & Prop Fabrication

Provide short-run displays, photo backdrops, and retail props from foam board, gatorboard, and corrugated plastic. The high-strength blades speed clean bevels and inside cuts, enabling quick turnarounds for events and pop-ups.

eCom Prep & Repack Service

Offer local FBA/eBay prep: box resizing, poly‑bagging, label windows, and protective inserts. Reliable blades help safely open cartons, trim void-fill, and resize corrugate, improving efficiency and presentation.

Vinyl Decal and Film Trimming

Provide on-site trimming for installed vinyl decals, window films, and paint-protection film edges. The sharp, stable blade body allows controlled scoring and edge cleanup around seals, hinges, and badges for a pro finish.

Creative

Precision Leather Wallet

Design and hand-cut a slim leather wallet using printable templates. The sharp, break-resistant blade lets you score and slice veg-tan leather cleanly for pockets, stitch grooves, and edge bevel setup, resulting in crisp seams and professional edges.

Custom Paint Stencils

Create reusable stencils from Mylar or acetate for wall art, signs, or fabric printing. The welded bi‑metal edge makes precise inside corners and smooth curves easier, producing clean paint edges and repeatable designs.

Foam Core Shadow Box

Build a layered shadow box from foam core and cardstock. The strong blade body resists flex while cutting multiple layers and long straight runs, giving tight miters and tidy window openings for a gallery-quality look.

Hand-Cut Paper Silhouettes

Turn profile photos into elegant paper silhouettes. Print, adhere as a guide to black cardstock, and cut smooth contours and hair detail with the sharp steel edge for striking framed art or greeting cards.

Chipboard Organizer Trays

Cut and assemble chipboard into drawer or desk organizer trays with finger joints and dividers. The durable blade slices dense board without chipping, yielding square, snug-fitting parts ready for glue and finish paper.