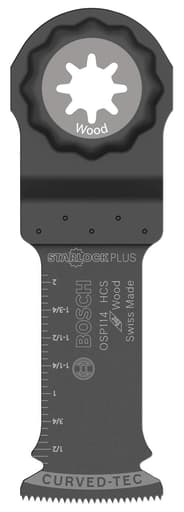

Features

- Bi-metal cutting edge for general-purpose use, including wood with nails

- StarlockPlus three-dimensional interface for increased torque transfer and reduced vibration

- Curved Tec blade shape for improved control and smoother plunge cuts

- Color-coded interface and laser-etched blade identification

- Swiss-made blade for dimensional precision

Specifications

| Model Number | OSP114F |

| Blade Width | 1.25 in (1-1/4 in) |

| Immersion Depth | 1.5 in |

| Material | Bi-metal (BIM) |

| Interface | StarlockPlus (compatible with StarlockPlus and StarlockMax tools) |

| Arbor Size | 0 |

| Weight | 0.0625 lb |

| Pack Quantity | 1 |

| Barcode/Gtin | 13389656 |

| Origin | Switzerland |

| Intended Use | Plunge cutting, general-purpose; suitable for wood with nails |

Related Tools

Related Articles

StarlockPlus oscillating multi-tool plunge-cut blade constructed with a bi-metal cutting edge. The StarlockPlus three-dimensional interface is designed to increase torque transfer and reduce vibration compared with a flat interface. The blade is intended for heavy-duty and general-purpose plunge cutting, including in wood with embedded nails, and is compatible with StarlockPlus and StarlockMax tool interfaces.

Bosch 1-1/4 In. StarlockPlus Oscillating Multi-Tool Bi-Metal Plunge Cut Blade Review

Why I reached for this Bosch bi‑metal plunge blade

On most renovation days, I need a blade that can plunge cleanly, stay controllable in tight spots, and survive a surprise nail or two. That’s why I’ve been running this Bosch bi‑metal plunge blade as my everyday cutter on a StarlockPlus multitool. After a few weeks of trim work, subfloor patches, and a deck repair, I have a solid feel for where it excels—and where it shows its limits.

Setup and compatibility

The StarlockPlus interface is the backbone here. The three‑dimensional mount snaps onto my tool with a positive, wiggle‑free lock, and the connection does translate to better torque transfer compared with older flat-interface or OIS-style blades. There’s no screw to fuss with, and the quick-change mount means I’m swapping blades one‑handed with gloves on.

Important note on fit: this blade is StarlockPlus and also works on StarlockMax tools. It does not fit basic Starlock or legacy OIS tools. If your multitool is StarlockPlus/Max, you’re set.

Build and design details

- Blade size: 1-1/4 in. wide, with a 1.5 in. plunge depth

- Material: Bi‑metal cutting edge (BIM)

- Weight: about an ounce

- Origin: Switzerland

Bosch’s Curved‑Tec profile on the leading edge is more than marketing fluff. That slight curve reduces the “grab” you sometimes get when initiating a plunge and spreads the cutting load across more teeth. The blade is visibly well made: flat, true, and with cleanly formed teeth. Laser‑etching on the face makes it easy to confirm the model and intended materials at a glance, and the color‑coded interface helps when you’re fishing in a crowded blade box.

Control and vibration

The rigid StarlockPlus mount pays dividends in feel. On my tool, vibration was noticeably lower than with generic OIS adapters and budget blades. That was most obvious during plunge starts and long, deep cuts in framing lumber. Less chatter means straighter cuts and fewer marred surfaces when you’re skimming past finished trim.

The 1‑1/4 in. width is a nice balance: narrow enough for detail and outlet box cutouts, wide enough for stable tracking along a line. At 1.5 in. depth, it reaches through 3/4 in. material and a subfloor face without bottoming out, though it won’t replace a long-reach wood blade for deep notches.

Cutting performance in wood

This blade’s sweet spot is wood—everything from soft pine casing to stubborn oak jambs. Plunge starts were smooth and predictable. In casings and baseboards, the Curved‑Tec edge let me feather the entry, easing in without skittering across the surface. I could score a clean line, pitch the tool slightly, and let the teeth self-feed without excessive downward pressure.

Speed and cut quality were consistent across species. In 2x SPF, the blade tracked straight and ejected chips well, so it didn’t heat up quickly. In hardwoods, it still cut cleanly, with the expected modest slowdown. Chip-out along the kerf was minimal when I kept the oscillation speed mid-range and let the blade, not force, do the work.

Encountering nails and screws

“Wood with nails” is always the promise that raises eyebrows. In practice, this blade handled the occasional 15–16 gauge finish nail like a champ. I purposely ran it through two nail-in-wood scenarios: removing old casing with hidden brads, and pocketing into subfloor around a ring-shank decking nail. In both cases, I could finish the cut without swapping to a dedicated metal blade. Teeth wear was evident afterward (you’ll feel a slight drop in bite), but not catastrophic.

As with any bi‑metal wood/metal blade, technique matters. If I heard that telltale ping of metal, I backed off the speed a notch, kept pressure light, and let the oscillation work. That preserved the edge far better than muscling through. I wouldn’t choose this as a primary metal cutter, but as a “nail insurance policy,” it earns its keep.

Metals and plastics

On soft metals—think thin aluminum trim or a rivet or two—it will make the cut. I tested on a handful of small aluminum rivets during a screen-door fix. It cut them, but the edge lost sharpness faster than it does in wood. That’s expected for a general-purpose bi‑metal profile. For frequent metal cutting or thicker screws, I’d switch to a dedicated carbide or fine-tooth metal blade.

In PVC and ABS, the blade tracked nicely with minimal melting when I kept the speed moderate and cleared chips frequently. It’s perfectly serviceable for outlet cutouts and plumbing notches in plastic.

Precision and finish

Dimensional precision is a quiet strength here. The blade is flat, the teeth are uniform, and the narrow kerf makes for tight cut lines. I used it for a few reveal-critical cuts—undercutting casing for tile, trimming shims flush to a jamb—and it left clean shoulders without the fuzzy “chew marks” cheaper blades sometimes leave. The 1.5 in. depth helps with flush trimming protruding material in a single pass, provided you mind your angle and let the curved edge ease in.

Durability and value

Longevity landed where I expect for a premium bi‑metal blade. In straight wood work, it stayed sharp longer than off-brand generics I keep as backups. After a couple days of mixed trim and subfloor tasks, the teeth were still biting well in pine and passably in hardwood. Contact with embedded nails or aluminum accelerates wear; that’s part of the bi‑metal bargain. If your job mixes frequent fasteners and abrasive materials, stepping up to a carbide tooth blade will pay off. Otherwise, this strikes a good balance of cost versus lifespan.

Price-wise, it sits on the higher side. You’re paying for the StarlockPlus interface, Swiss manufacturing, and better-than-generic longevity. If you’re using your oscillating tool regularly, the improved control and reduced vibration alone are worth a few extra dollars; fewer ruined cut lines and less hand fatigue show up fast on the job.

Tips for best results

- Use mid-range oscillation speed for plunge starts; ramp up as the kerf establishes.

- If you hit metal, lighten pressure and drop speed one or two settings to protect the teeth.

- Score your cut line with a knife or make a shallow pilot plunge to minimize surface chipping on finished stock.

- Keep the blade moving; dwelling in one spot builds heat and dulls the edge faster.

- Let the Curved‑Tec edge do its thing—rock slightly on entry for a smoother start.

- Mark the 1.5 in. depth on your tool shoe with tape for quick visual reference when pocketing.

Who it’s for

This StarlockPlus plunge blade is a smart everyday choice for carpenters, remodelers, and DIYers who use a multitool as a problem-solver: undercutting trim, notching subfloors, cutting in outlets, trimming shims, and handling the odd hidden nail without swapping blades. If your work is metal-heavy—fastener removal, nail slicing all day, or demo through screws—consider a carbide tooth option as your primary and keep this as your wood specialist.

Final recommendation

I recommend this Bosch bi‑metal plunge blade for anyone running a StarlockPlus or StarlockMax multitool who needs a reliable, controllable, general-purpose cutter for wood and composites with occasional fastener encounters. It stands out for its secure interface, low vibration, smooth plunge starts, and clean cut quality. It’s not a metal-first blade, and it isn’t the cheapest option, but the combination of precision, handling, and respectable durability makes it a dependable everyday blade in my kit.

Project Ideas

Business

Trim & Flooring Precision Cut Service

Offer door-jamb undercutting for new flooring, flush cuts at casing and baseboards, and clean register/vent cutouts in hardwood. The 1.5 in plunge depth and curved entry allow accurate, clean cuts with minimal tear-out, making on-site work fast and tidy.

Cabinet Modification & Appliance Fitment

A mobile service to adapt existing cabinetry for new appliances, sinks, or lighting. Plunge cut openings for outlets, vents, and under-cabinet lighting channels. The vibration-damping interface gives cleaner edges in finished kitchens and reduces rework and dust.

Reclaimed Lumber Prep & Products

Source pallets/barn wood and use the bi-metal blade to process stock without pulling every nail. Sell cleaned boards, charcuterie blanks, or mosaic kits. Market the speed and safety advantage of cutting through fastener-prone wood with minimal waste.

Selective Demo & Retrofit Cut‑Ins

Provide surgical cut-ins for electricians, plumbers, and low-voltage installers: outlet boxes, access panels, and notch cuts in framing or sheathing, even where nails are present. Precision plunge cuts reduce overcuts and patching time, speeding multi-trade projects.

Van/RV/Boat Custom Interior Cutouts

Specialize in installing vents, hardware, cable chases, and access hatches in tight spaces. The compact 1.25 in blade excels at controlled plunge cuts with minimal vibration—ideal for thin cabinetry, paneling, and composite cores without splintering.

Creative

Hidden Cord Channels in Furniture

Retrofit credenzas, TV stands, and desks with clean cable management. Use precise plunge cuts to create 1.25 in wide, up-to-1.5 in deep channels and pass-throughs for power strips and chargers. The curved plunge profile helps start cuts exactly where needed, and the bi-metal edge lets you work safely through old casework that may have hidden brads or staples.

Reclaimed Wood Mosaic Wall Art

Turn nail-riddled pallet or barn wood into geometric mosaics. The bi-metal blade handles wood with embedded nails, so you can square edges, create tight seams, and flush-trim pieces without stopping to pull every fastener. The low-vibration StarlockPlus interface helps maintain crisp lines on small, intricate segments.

Concealed-LED Slat Feature Wall

Build a modern slat wall with hidden LED strips and service access. Plunge cut neat raceways, junction pockets, and access knockouts behind slats without overcutting. The 1.25 in blade width is ideal for consistent channels and the smooth plunge action reduces tear-out on visible faces.

Secret Compartment Puzzle Box

Craft a small box with sliding panels, magnet catches, and hidden keyholes. Use the blade to plunge precision slots for runners and latches and to cut reliefs for thin magnet recesses. The controlled plunge lets you stop right at layout lines for tight, satisfying mechanisms.

Live-Edge Shelf with Hidden Magnetic Mounts

Create a floating shelf that doubles as a key/knife holder. Plunge recesses for rare-earth magnets and keyhole hangers on the back, even if the slab has old nails. The bi-metal tooth design keeps you cutting confidently through reclaimed stock without blade-damaging surprises.