Features

- Softer abrasive formulation for faster material removal on harder metals

- Three full sheets of fiberglass reinforcement for increased durability and safety

- Aluminum oxide abrasive suitable for general metal grinding

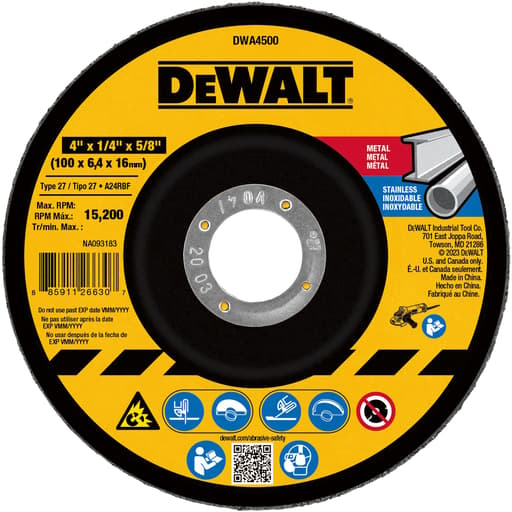

Specifications

| Diameter | 4 in |

| Arbor Size | 5/8 in |

| Disc Thickness | 1/4 in |

| Abrasive Material | HP Aluminum Oxide |

| Grit | A24N |

| Package Quantity | 25 |

| Maximum Operating Speed | 15,200 RPM |

| Upc | 885911266307 |

| Approximate Weight (Per Package) | 7.5 lbs (25 pieces) / ~0.4 lb (single wheel) |

Related Tools

Related Articles

4-inch Type 27 grinding wheel intended for metalworking tasks such as smoothing welds, deburring, and surface preparation. It uses an aluminum-oxide abrasive formulated to remove material from harder metals more quickly and includes fiberglass reinforcement for structural durability. Fits a 5/8" arbor.

DeWalt Type 27 Metal Grinding Wheel Review

Why I reached for this wheel

I put this 4-inch DeWalt wheel to work on a stack of shop tasks that usually send lesser abrasives to the trash: knocking down MIG welds on A36 plate, beveling 3/16-inch angle for fit-up, dressing flame-cut edges, and cleaning up mill scale ahead of primer. It’s a Type 27 depressed-center wheel with a coarse, aluminum-oxide grain and a relatively soft bonding formulation. On paper, that mix promises fast stock removal on tough material with a trade-off in wheel life. In practice, that’s more or less what I experienced—quick, predictable cutting with a finish that’s appropriate for grinding, not blending.

Setup and compatibility

This wheel uses a 5/8-inch arbor. That’s important. Many 4-1/2-inch grinders in the U.S. are set up for 7/8-inch arbor-hole accessories (or have 5/8-11 threaded hubs). If your grinder expects a 7/8-inch wheel or a threaded hub, you’ll need the correct flanges or a grinder that specifically accepts 5/8-inch-bore depressed-center wheels. On my compact 4-inch grinder, the wheel seated properly on the OEM flanges with the guard in place and cleared.

A few quick setup notes from the bench:

- Respect the 15,200 RPM maximum. Most 4-inch grinders fall under that; confirm your no-load speed.

- Keep the guard on. The wheel’s 1/4-inch thickness is meant for grinding, not cutting, and the guard keeps the working angle consistent.

- Aim for a 15–30 degree approach to the work. With the Type 27 shape, I got the best bite and control right around 20 degrees.

Performance on common shop metals

Mild steel (A36 plate and angle): The wheel chewed through weld crowns quickly and evenly. It didn’t glaze under reasonable pressure, and it tolerated heavier pushes when I needed to flatten a bead fast. The aggressive 24-grit cut left a uniform, coarse pattern that’s fine for subsequent fabrication steps or primer, but not a final finish.

Hot-rolled scale and mill edges: The soft-bond formulation helped keep fresh grain exposed, so scale removal stayed brisk without the wheel skittering. I noticed fewer “hot spots” than with harder, longer-wearing wheels that tend to skate or chatter on hard skin.

Harder steels (4130, heat-affected zones near welds): The wheel maintained a strong bite. I could feel the bond releasing worn grain to prevent glazing, which preserves speed at the expense of longevity. If you’re doing extended work on alloy steels, this is exactly the behavior you want for consistent removal.

Stainless: It grinds stainless just fine from a pure material-removal standpoint. However, this isn’t a contaminant-free INOX wheel. If you’re doing stainless that must be cosmetically clean or corrosion-resistant after finishing, be mindful of potential contamination and consider a dedicated stainless wheel for final passes. For rough prep or weld knockdown on stainless that will be further finished, it worked adequately.

Thin gauge sheet: It’s easy to overdo it. The 1/4-inch thickness and coarse grit will introduce heat and gouge if you’re not careful. I used a very light touch for edge cleanup and switched to a flap disc for blending.

Speed vs. lifespan trade-off

This wheel is formulated on the softer side to stay sharp on harder metals. The upside is speed. Even on stubborn welds and heat-affected zones, I kept a consistent cut rate without needing to constantly shift angles to find fresh grit. The downside is predictable: it wears faster than harder, longer-lived wheels. Over several sessions of weld knockdowns and beveling, I went through wheels at an expected pace for a soft-bond, coarse-grit disc. If your priority is relentless stock removal with steady feel, this balance makes sense. If you’re chasing maximum wheel life per dollar on easier materials, a harder bond or a ceramic grain alternative may outlast it.

Cut quality and control

The wheel tracks true. I didn’t see wobble or eccentricity out of the box, and it remained stable as it wore down. The depressed center gives enough clearance to work edges without the nut interfering, and the 1/4-inch thickness provides a reassuring, planted feel when you’re leaning into a weld bead. It’s not a finesse tool for blending; it’s for making metal disappear. For surface prep where appearance matters, I followed with a 60–80 grit flap disc and had no trouble removing the grind marks.

One nice characteristic: the wheel feels predictable across variable pressure. Some hard-bond wheels go from “slow” to “scorched” in an instant. This one lets you modulate pressure to control heat and depth with less drama.

Heat and debris

Aggressive grinding makes heat. This wheel is no exception, but the soft bond keeps it cutting cool relative to its class. If I stayed moving, I avoided blueing on mild steel. If I stalled in one spot, it would generate typical heat and discoloration. The spark stream is dense and coarse, which tells you it’s removing material. PPE is mandatory: full face shield, gloves, ear protection, and a proper dust mask. The fiberglass reinforcement is there for safety, but technique and protection matter more.

Safety and durability

Three full sheets of fiberglass reinforcement give this wheel a sturdy backbone. I didn’t experience edge shedding or chunking, even after accidentally nicking a clamp jaw. As always, discard the wheel if you drop it—any abrasive can be compromised by impact—and store the pack flat in a dry area to prevent moisture from affecting the bond.

The 1/4-inch thickness is appropriate for grinding, not cutting. If you need to slot or cut off, use a dedicated cutoff wheel; trying to cross over will feel sluggish and could encourage unsafe side-loading.

Value and packaging

The standard pack is 25 wheels at roughly 7.5 pounds total. In a small fab shop, that’s an appropriate quantity that keeps you from running out mid-job. For occasional users, 25 may be more than you need—verify availability as single wheels or smaller sleeves if space or budget is tight. From a value standpoint, you’re getting fast-cutting performance and consistent behavior. You’ll likely consume them a bit faster than harder-wearing discs on mild work, but you save time on tasks where speed matters, especially around welds and hard zones.

Where it fits in a kit

- Use this wheel when you need to remove a lot of metal fast: weld crowns, bevel prep, heavy scale, and dressing rough cuts.

- Follow with a flap disc for blending.

- Switch to a contaminant-free wheel when finishing stainless or nonferrous-sensitive parts.

- Consider ceramic-grain wheels if you routinely grind alloy steels and want longer life per wheel, accepting a higher upfront cost.

Tips from the shop floor

- Keep your angle between 15–30 degrees and use steady, moderate pressure. Let the bond refresh the grain rather than forcing it.

- Dress sharp corners first. The wheel’s 1/4-inch body will hold shape well enough to trace bevels accurately.

- Mark stainless zones if you’re concerned about contamination and reserve fresh wheels for those areas.

- Check your grinder’s arbor and speed before you buy. This is a 5/8-inch bore wheel rated to 15,200 RPM.

The bottom line

This 4-inch DeWalt wheel does what a Type 27 grinder wheel should: it removes metal quickly, tracks predictably, and stays safe under normal shop use. The soft-bond, coarse aluminum-oxide grain keeps it cutting on tougher material without excessive glazing, and the triple-fiberglass reinforcement inspires confidence. The trade-off is expected—faster cutting means faster wear—but the time saved on aggressive tasks balances that out for most fabrication work.

Recommendation: I recommend this wheel for anyone running a compatible 4-inch grinder who prioritizes fast stock removal on steel, welds, and scale. It’s a dependable, no-surprises choice for fabrication and repair work where productivity matters more than stretching every last millimeter of wheel life. If your workflow leans heavily on stainless finishing or you need maximum life on mild steel, supplement it with a dedicated INOX wheel or a harder-bond/ceramic option. For general metal grinding, this DeWalt is an easy wheel to keep in the shop.

Project Ideas

Business

Weld Cleanup & Finish Subcontracting

Offer a service to local welders and small fab shops to handle weld blending, slag removal, and surface prep. Price by the part or linear foot, provide quick turnarounds, and standardize finish levels (e.g., blend-only, blend + prime-ready). Keep inventory of 4" Type 27 wheels for consistent results.

Metal Art & Home Decor Line

Produce grind-textured wall art, minimalist planters, and small furniture pieces for Etsy and local markets. Emphasize durable construction, safe deburred edges, and distinctive grind patterns. Batch work using the 25-pack of wheels to control costs and margins.

Property & Facility Metal Repair

Provide on-site grinding and repair for railings, gates, stair treads, and signposts. Services include deburring hazards, smoothing weld repairs, removing rust/scale for repainting, and compliance-focused edge finishing for commercial properties and HOAs.

Powder-Coat/Paint Prep Partner

Partner with powder coaters and painters to deliver clean, uniform, profile-ready steel. Offer weld spatter removal, edge rounding, and surface prep prior to media blasting or coating. Bundle pickup/drop-off for small fab shops that lack finishing capacity.

Intro to Grinder Finishing Workshops

Host short classes for makers and hobbyists on safe angle grinder use, weld blending, edge treatment, and surface prep. Charge per seat, include PPE checklists, and provide practice stock. Sell consumables (Type 27 wheels) and offer discounted finishing services to attendees.

Creative

Reclaimed Steel Side Table

Build an industrial-style side table from angle iron and a salvaged steel plate top. Use the Type 27 wheel to bevel edges for tight welds, flush-blend the seams, and remove mill scale for a clean, paint-ready surface. Add ground-in decorative chamfers along the tabletop for a refined look.

Layered Metal Wall Art

Create a multi-layer steel wall piece with cut silhouettes (letters, skyline, nature motifs). Use the wheel to deburr edges, add intentional grind patterns for texture, and blend welds on stand-offs to give the art depth. Finish with contrasting patinas or clear coat to showcase the grind marks.

Upcycled Garden Planters

Turn scrap tubing or old steel pipe into modern planters. The grinding wheel helps knock off rust and scale, smooth sharp edges, and blend any added brackets or feet. Add drainage holes and a weatherproof coating for a durable outdoor finish.

Custom Fire Pit Ring

Fabricate a round or polygonal fire pit ring from mild steel sheet with welded seams. Use the wheel to dress the welds, round over top edges, and remove spatter. Add decorative cutouts and highlight them by lightly grinding for bright, contrasting bare metal before high-temp coating.

Bottle Openers and Key Hooks

Make small giftable items from flat bar: bottle openers, wall-mounted key hooks, and coat hooks. The wheel quickly shapes profiles, chamfers edges, and blends welds where hooks meet backplates. Polish select areas to a bright grind finish and seal with a clear coat.