Features

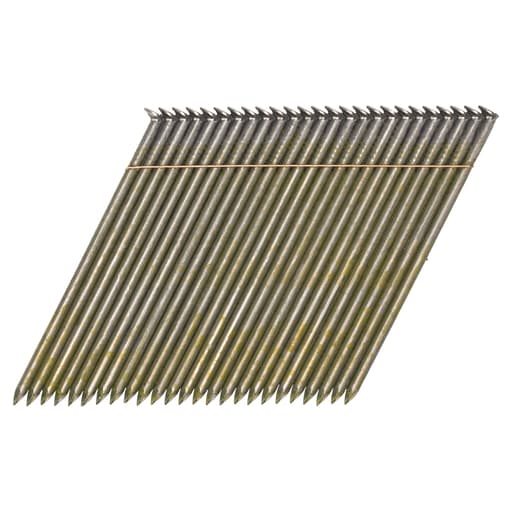

- Wire collated (strip loading)

- Smooth shank for easier penetration

- Bright finish and coated for improved holding

- Full/offset round head to increase holding power

- 2000 nails per box

- ACQ rated (suitable for treated lumber applications)

Specifications

| Fastener Callout Size | 3-1/2 in. x 0.131 in. |

| Nail Length | 3.5 in. |

| Fastener Head Width / Diameter | 0.131 in. |

| Nail Angle | 28 degree |

| Shank Type | Smooth shank |

| Head Style | Offset / full round head |

| Collation Material | Wire |

| Fastener Material | Metal |

| Finish / Coating | Bright finish (coated) |

| Nail Penny Size (D) | 16d |

| Nails Per Box | 2000 |

| Loading Type | Strip |

| Interior / Exterior | Interior |

| Product Weight | 26.56 lb (box) |

| Package Dimensions (L × W × H) | 10.5 in × 5.9 in × 4.7 in |

| Returnable | 90-Day |

Boxed wire-collated framing nails intended for interior framing applications. Smooth shank nails with a bright finish and coating to aid holding power and penetration. Full/offset round heads increase holding capacity. Supplied in strips (wire collation) with 2,000 nails per box; designed for use with 28° wire-collated framing nailers.

DeWalt 3-1/2 in. x 0.131 in. Wire collated smooth shank framing nails Review

First impressions and setup

A framing nailer is only as good as the sticks you feed it. I ran two boxes of these DeWalt 16d wire‑collated nails through a 28° nailer while framing a shed and a basement partition, and they behaved the way consumables should: predictably, consistently, and without drama. The strips arrived straight with clean welds, no bent points, and no flaking coating. Loading into a 28° wire‑collated magazine was simple—the angle and strip stiffness make them easy to drop in one‑handed without fighting the follower.

Quick compatibility note: these are 28° wire‑collated nails. They’re not for 21° plastic or 30–34° paper nailers. Some nailers are tolerant of slight angle differences, but most aren’t; match your nailer exactly to avoid headaches. If you’re already running a DeWalt or similar 28° wire gun, you’re set.

Specs that matter on site

- Size: 3‑1/2 in. x 0.131 in. (16d)

- Shank: Smooth

- Head: Offset/full round

- Collation: Wire, strip‑loaded

- Finish: Bright with a friction‑activated coating

- Nails per box: 2,000

The 0.131 in. shank is the sweet spot for general framing in SPF and SYP. The offset/full round head provides wide bearing for better holding at the plate and helps with inspectors in jurisdictions that prefer or require full‑head nails. Being wire‑collated, the strips hold together in damp conditions better than paper, and they don’t produce the brittle shards that plastic collation leaves behind.

Driving performance

Out of the box, the nails fed smoothly. Over several thousand shots, I didn’t experience a single nail that was out‑of‑spec enough to cause a misfeed. Depth of drive was consistent across stud faces and sill plates. The coating on these nails earns its keep: once the point breaks the surface, the nail slides in cleanly, then grabs as the coating heats. I noticed fewer half‑set “kickers” compared with uncoated brights, especially when toe‑nailing through kiln‑dried studs.

In dense Southern yellow pine, they still sank flush or slightly proud depending on the grain and knot content, which is normal behavior. A quick depth adjustment on the gun took care of that. I also appreciated that the points are sharp without being needle‑fine; they start quickly but don’t tend to follow the grain off line on toe‑nails.

Jams were rare. Wire‑collated strips can occasionally shed a fragment that tries to tag along; here, the welds were tidy and the wire ended cleanly as each nail fired. I found less collation scrap in the nose than I’m used to with cheaper wire strips. And unlike plastic‑collated nails, there’s no shower of plastic chips bouncing back at your face—still wear eye protection, but cleanup is easier.

Holding power and where these shine

These are smooth‑shank nails. That means they drive fast and split less, but they don’t have the same withdrawal resistance as ring‑shanks. For framing walls, plates, headers, and general studwork, they’re exactly what I want: fast, consistent, and strong enough in shear with that full/offset round head. The head helps prevent pull‑through on plates and at corners, and the coating adds meaningful bite once it cools.

If I’m fastening subfloor or sheathing where long‑term squeak resistance matters, I’ll switch to ring‑shanks. For deck framing or fences, I go galvanized or stainless. But for interior framing, stair stringers inside conditioned space, and treated sill plates under a house, these nails hit the target.

ACQ rating and corrosion considerations

DeWalt lists these as ACQ rated, and I used them in pressure‑treated sill plates without any immediate discoloration or obvious reaction. That ACQ compatibility is about the nail’s coating and material not reacting aggressively with the chemicals in modern treated lumber. Still, the finish is “bright,” not hot‑dipped galvanized or stainless. I wouldn’t use bright‑finished nails where they’ll be exposed to weather or high humidity over the long term. For exterior and coastal work, choose HDG or stainless. For interior or covered applications—including treated sill plates—these are appropriate and efficient.

Real‑world handling

- Wire vs. plastic debris: Wire fragments are few, and you can sweep them with a magnet. I prefer this over the blast of plastic shards you get with 21° nails.

- Strip durability: The strips held together bouncing around in a pouch and riding in the truck. No cascading breaks when I snapped a strip mid‑load.

- Box practicality: At a little over 26 lb, the carton is manageable, and the footprint fits neatly on a shelf. The count (2,000) is enough to carry a small project without constant reordering.

- Magazine fit: Offset/full round heads allow slightly tighter staggering, which translates to decent magazine capacity. I didn’t notice any rubbing or drag that sometimes happens with larger head profiles.

Precision and consistency

Nail length and head geometry were uniform. The heads seated evenly without eccentric mushrooming that can happen with softer wire. Point alignment on the strips was straight; that matters for toe‑nailing because you want the nail to leave the nose the moment you expect it to. I didn’t see any double‑feeds or nails welded too tightly to the wire to release cleanly.

One minor note: on a handful of shots into old, dry Doug fir, I got a faint whiff from the coating as it set—normal for coated nails and not offensive, but worth mentioning if you’re sensitive to odors in enclosed spaces.

Use cases and caveats

- Interior framing: Ideal. Studs, plates, headers, blocking—fast and consistent.

- Treated lumber (covered): Fine for sill plates and interior PT where ACQ compatibility matters but weather exposure doesn’t.

- Exterior exposure: Not recommended. Use galvanized or stainless.

- Sheathing/subfloor: Usable, but I prefer ring‑shanks to reduce the chance of movement over time.

- Structural connectors: Don’t substitute these for connector‑rated nails. Use the specific nails your hanger manufacturer calls out.

Tips for best results

- Match your angle: 28° wire‑collated only. Don’t force them into a 21° or 30° nailer.

- Tune depth early: The coating changes drive feel; set your depth on scrap PT and kiln‑dried stock before production.

- Keep a magnetic sweeper: It makes collecting wire fragments quick.

- Rotate the gun for toe‑nails: Smooth shanks toe‑nail cleanly—use the gun’s contact tip angles to avoid wandering around knots.

Value

These aren’t boutique nails, and that’s a compliment. They do the unglamorous work of framing without calling attention to themselves. The 2,000‑count box is priced fairly in my market, and the time saved from fewer misfeeds and clean drive behavior outweighs any marginal premium over bargain nails. If you frame even occasionally, buying by the box makes sense and will likely carry you through a shed, a room addition, or a basement build‑out.

The bottom line

DeWalt’s 16d wire‑collated framing nails are reliable consumables for 28° nailers. They feed smoothly, drive consistently, and offer solid holding power for interior framing thanks to a friction‑activated coating and a full/offset round head. The ACQ rating makes them appropriate for treated lumber in covered conditions, while the bright finish rightly keeps them out of the weather. Their few limitations—smooth shank withdrawal versus ring‑shank alternatives, and incompatibility with non‑28° nailers—are predictable and easy to plan around.

Recommendation: I recommend these for anyone doing interior framing with a 28° wire‑collated nailer. They’ve been consistent, jam‑free, and efficient in real work, and the 2,000‑count box is a practical size for small to mid‑sized projects. For exterior or long‑term moisture exposure, step up to galvanized or stainless; for sheathing and subfloors, choose ring‑shanks. Used where they’re intended, these nails are exactly what you want: dependable and unremarkable—in the best way.

Project Ideas

Business

Basement & Interior Framing Packages

Offer fixed-price framing packages for basements, home offices, and utility rooms. Standardize around 28° nailers and these 3-1/2 in. coated nails for speed and code-friendly full/offset round heads. Provide material takeoffs, nailer + nails, and rapid install crews to deliver framed, ready-to-insulate spaces.

Pre-Framed Partition Wall Kits

Manufacture knockdown interior wall modules (labeled studs, headers, plates) pre-assembled in segments with these nails, designed to fit through doorways. Deliver kits with layout plans and hardware for easy DIY install. Ideal for home offices, studios, and retail buildouts.

Event/Film Set Flats Fabrication

Build standardized stud-backed scenic flats and platforms using 2x frames nailed with 28° wire-collated strips for fast throughput. Rent or sell to theaters, production companies, and event planners. Smooth shank nails speed production while still providing adequate holding in temporary indoor applications.

Mobile Framing Gun + Consumables Service

Run a mobile supply and support service for small contractors: on-site delivery of 28° nailers, these 16d nail boxes, fuel/air accessories, and quick maintenance. Offer subscription restock plans and emergency drop-offs to keep crews productive.

Water/Fire Remediation Reframe Crew

Specialize in quick tear-out and reframing of damaged interior walls for restoration firms. Standardize tooling with 28° nailers and these coated, ACQ-rated nails for treated sill plates and contact areas in basements or crawlspaces (in covered/interior conditions). Emphasize speed, cleanliness, and documentation for insurers.

Creative

Freestanding Workshop Tool Wall

Build a stud-framed, freestanding pegboard wall for a garage or studio. Use the 3-1/2 in. 16d, 28° wire-collated nails to assemble a rigid 2x4 frame with cross-bracing, then skin one side with plywood and pegboard. The full/offset round heads give great holding power for structural joints, and the smooth shank with coating speeds assembly with a 28° nailer.

Acoustic Slat Feature Wall

Create a sound-dampening slat wall by framing a shallow, insulated cavity and attaching furring strips over acoustic felt. The nails’ coated, bright finish is suited for interior framing, and their length ensures solid grabs into studs. Adds modern aesthetics while improving room acoustics for a media room or studio.

Indoor Climbing/Bouldering Panel

Frame a robust substructure for a home bouldering wall using 2x lumber fastened with these nails, then bolt on plywood panels with T-nuts. The nails provide fast assembly for the hidden structural frame, while you mechanically fasten the panels. Ideal for basements or garages where interior-rated fasteners are appropriate.

Hidden-Bracket Floating Shelves

Build torsion-box shelf cores with 2x framing ripped to size and nailed together, then skin with plywood. The long 16d nails create strong internal frames that mount to wall studs, supporting heavy loads. Finish with veneer or paint for a sleek, floating look.

Modular Room Divider/Partition

Construct movable partition wall modules (stud frames with lightweight skins) to zone open spaces. Use the 28° collated nails for fast, repeatable framing in jigs. Include removable feet or casters. Interior-rated nails are perfect for these indoor, non-load-bearing applications.