Features

- 10-inch diameter blade

- 24 cutting teeth

- Designed for brush saw use

- Sold as a single replacement blade

Specifications

| Diameter | 10 in |

| Tooth Count | 24 |

| Price | $36.99 (USD) |

| Sku | 1070659 |

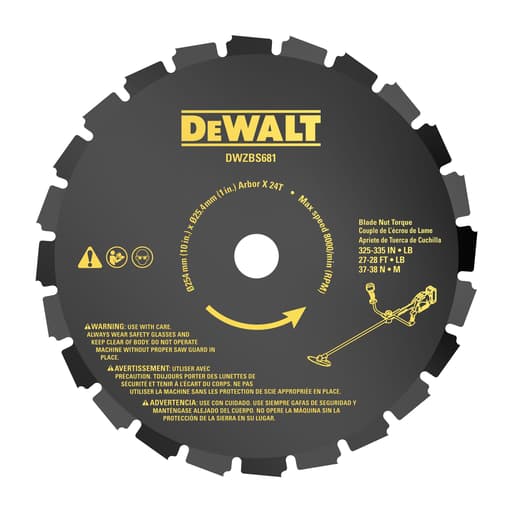

| Manufacturer Part Number | DWZBS681 |

| Stock Status | In stock |

Related Tools

Related Articles

10-inch replacement blade intended for brush saws. It has 24 cutting teeth and is intended for cutting brush and similar vegetation.

DeWalt Replacement Brush Saw Blade Review

Why this blade earned a spot in my clearing kit

Brush clearing is one of those jobs where the right blade turns an exhausting slog into a steady rhythm. After several sessions with DeWalt’s 10-inch brush blade on a handful of overgrown properties, I’ve come away impressed by how reliably it cuts and how little fuss it requires. It’s a straightforward, 24-tooth disc designed for brush saws, and it leans into that simplicity: no gimmicks, just a solid bite on woody stems and scrub.

Setup and compatibility

The blade ships as a single, bare replacement—no hardware, no bushings, no instruction leaflet. That’s typical for this category, but worth noting if you’re new to circular brush blades. You’ll need to use the clamping washers, flange, and any arbor adapter specified for your saw. I mounted it on a clearing saw with a standard guard and blade cup, following the saw manufacturer’s sequence and torque spec.

A small tip if you’re new to these: before tightening the nut, double-check the tooth orientation relative to your saw’s rotation. The teeth should “lead” into the cut. Without instructions in the packaging, it’s easy for a first-timer to second-guess this. Once oriented correctly and snugged down, the blade tracked true with no noticeable wobble.

Cutting performance

This blade is happiest in the dense, mixed material that drives string trimmers to their knees: blackberry canes, saplings up to a couple of inches, sumac shoots, wild rose, and sapling-studded grass margins. The 24-tooth pattern strikes a sensible balance—aggressive enough to pull cleanly through woody stems without hanging up, yet refined enough to avoid shredding and whipping smaller brush.

In practice, it feeds well at a moderate pace. I could keep a smooth arc through 1–2 inch saplings without the machine bogging or the blade skating off the cut. On softer species and green growth, the cut is surprisingly neat; I didn’t get the ragged splintering that can happen with very coarse, low-tooth-count brush discs. It also sheds chips cleanly, which helps keep the cut line visible and prevents the “snowplow” effect that slows progress in heavy thickets.

If your work skews toward thicker hardwood, this blade will still make the cut, but you’ll be nudging the upper end of its comfort zone as diameters approach 3 inches. A higher-tooth forestry blade or a chainsaw becomes the better tool beyond that.

Control, smoothness, and noise

One thing I appreciated is how predictable the bite feels. With some brush blades, you get a grabby moment right as the tooth engages, especially when you catch a fibrous stem at an angle. Here, the engagement is gentle enough that I could maintain a consistent sweeping motion without bracing for a jolt. That reduces fatigue over a long session.

Vibration was low on my setup, provided the blade stayed out of the dirt. Hit a rock or wire, and you’ll feel the consequences immediately—any brush blade will transmit that impact. On balance, though, it runs smoothly and a touch quieter than finer-tooth discs, which tend to sing at high RPM. The overall “sound profile” feels less shrill and more of a steady cutting hum.

Durability and edge holding

Edge life on a brush blade is hard to generalize because ground contact, hidden fencing, and mineral-heavy weeds can undo a fresh edge in seconds. Within those realities, this blade held up well for me across several hours of clearing mixed brush and young saplings. I avoided grit where I could, paused to knock mud off the stems before cutting near the ground, and the teeth stayed sharp enough to keep chips flying.

The 24-tooth count also makes touch-ups practical. Fewer teeth mean quicker filing, and the profile here is straightforward to re-hone with a flat or triangular file and a simple guide. I did a light maintenance pass between sessions and restored a crisp edge without much effort. If you push primarily through dry, knotty hardwood or you tend to work close to rocky soil, plan on more frequent touch-ups—this is true of any steel brush blade.

Safety and handling notes

Brush blades deserve respect. The usual cautions apply: full PPE (face shield, eye and ear protection, gloves, boots), a proper harness, and a functioning blade guard. Keep the material at waist height or below, and cut at or near full throttle where the blade is most stable. For stems above your comfort diameter, don’t force it; step up to a more appropriate tool.

I found the blade less prone to kickback than some aggressive cutters when used with a sweeping technique and light feed pressure. Still, be mindful when you’re cutting at the blade’s edge, especially near irregular terrain or hidden obstacles. If you hit wire or rock, stop and inspect the teeth before continuing.

Where it shines—and where it doesn’t

Strengths:

- Fast, confident cuts in woody brush, briars, and saplings up to a couple of inches.

- Smooth engagement with low tendency to grab if you maintain a steady arc.

- Easy to maintain; fewer teeth mean faster sharpening.

- Good chip evacuation keeps the cut visible.

Limitations:

- Not the ideal tool for matted grass or soft weeds; a tri-knife or string head is better there.

- As diameters approach 3 inches in tougher hardwoods, efficiency drops.

- Packaging doesn’t include guidance, so first-time installers may want to consult their saw manual or a reliable setup video.

Value

At $36.99, it hits a reasonable middle ground. There are cheaper generic discs that cut adequately for light-duty use, but they often trade away balance, edge life, or flatness. On the other end, specialized or carbide-tipped options cost more and make sense only if you’re consistently tackling abrasive material or need maximum edge life. For most routine brush clearing, this blade offers a sensible mix of performance and price.

Tips for getting the most out of it

- Keep it clean. Mud and sap bake onto teeth and slow the cut. A quick wipe with a resin remover after a session pays off.

- Avoid ground strikes. Start cuts slightly above soil level, then finish the stump with a controlled pass if needed.

- Maintain often. A light touch-up before the edge is dull restores performance quickly and reduces fatigue.

- Check fasteners. Re-torque the blade nut after the first few minutes of running; components can settle.

Final thoughts

This 10-inch brush blade does exactly what I want from a general-purpose clearing disc: it bites confidently into brush and small saplings, runs smoothly with minimal drama, and is straightforward to maintain. It doesn’t try to be a do-everything cutter, and that’s a strength. If your workload is a mix of thorny thickets, volunteer saplings, and woody edges that need taming, it’s easy to recommend.

Recommendation: I recommend this blade for homeowners, land managers, and trail crews who need a reliable, no-nonsense cutter for woody brush and small-diameter saplings. It delivers consistent performance, is easy to keep sharp, and offers solid value for the price. If your clearing involves heavy hardwood over 3 inches or abrasive, rocky conditions, consider a different blade class; otherwise, this one is a dependable choice for day-in, day-out brush work.

Project Ideas

Business

Brush & Understory Clearing Service

Offer per-hour or per-acre clearing for homeowners, farms, and HOAs. Specialize in saplings, briars, and heavy brush using 10-inch, 24T blades. Bundle services with haul-away, chipper add-ons, and a seasonal maintenance plan.

Vineyard/Orchard Floor Management

Provide canopy-safe understory cutting around vines and trees where mowers can’t reach. Sell monthly or harvest-season packages and keep an inventory of replacement blades to minimize downtime.

Fence Line & Pasture Reclaim

Target ranches and rural properties to clear fence lines, gates, and perimeters. Offer before/after drone photos, fast turnarounds, and discounted follow-up trims. Upsell blade replacements as consumables in quotes.

Trail and Park Maintenance Contracts

Bid recurring contracts with municipalities and land trusts for trail corridor brushing, sightline clearing, and invasive cutbacks. Standardize crews with spare 10-inch blades and track blade wear in job costing.

Blade Sharpening & Exchange Subscription

Run a monthly pickup/exchange for contractors: drop off dulled blades, deliver sharpened or new replacements. Offer tiered pricing, on-site swaps, and recycling for spent blades.

Creative

Dulled-Blade Wall Clock

Upcycle a retired 10-inch blade into an industrial wall clock. Clean, paint or patina the blade, dull and seal the teeth, then mount a clock movement through the arbor hole for a rugged garage or shop accent.

Kinetic Garden Sun-Catcher

Make a wind spinner using two dulled blades suspended on swivels. The toothed edges create shimmering light patterns and can deter birds. Cap or encase edges with clear epoxy or rubber trim for safety.

Trail Stewardship Awards

Engrave or laser-etch volunteer names and dates onto dulled blades and mount them on wooden plaques. Perfect for trail groups or land trusts recognizing brush-clearing efforts.

Industrial Planter Stand

Use a dulled blade as a circular base for a small plant stand. Encapsulate the teeth in resin or fit a rubber edge guard, then weld or bolt a short riser and top plate for a sturdy, gritty look.

Printmaking Texture Plate

Ink a dulled blade and press it onto paper or fabric to create repeating radial tooth patterns. Great for poster art, shop branding, or textile accents without cutting risk.