Features

- Optimized tooth geometry for straight, precise cuts

- Face-ground teeth to minimize splintering and improve surface finish

- Micro-grain carbide teeth for clean cutting

- Patented body slots to reduce vibration

- ToughCoat anti-stick coating to reduce friction and gumming

- Thin kerf design for smoother cuts and reduced material removal

Specifications

| Arbor Size | 5/8 in |

| Diameter | 7-1/4 in |

| Number Of Teeth | 40 |

| Tooth/Hook Angle | 7° |

| Kerf Thickness | 0.063 in |

| Material | Carbide tipped |

| Maximum Speed | 9000 rpm |

| Intended Material | Wood |

| Number In Package | 1 |

Related Tools

Related Articles

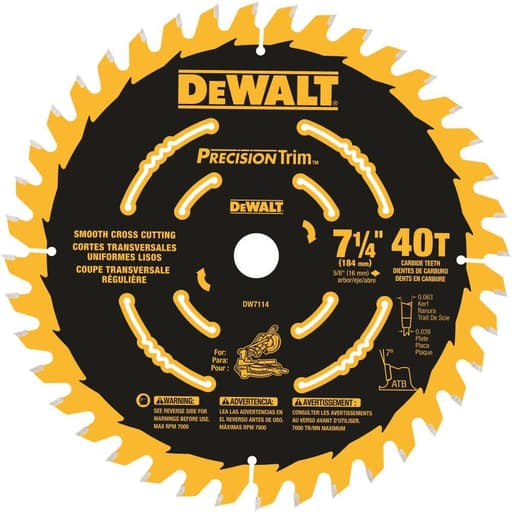

7-1/4 in. precision trim miter saw blade with a laser-cut body and micro-grain carbide teeth. Designed for crosscutting wood; face-ground teeth and an optimized tooth geometry reduce splintering and help produce straight cuts. Body slots and a thin-kerf design reduce vibration and material removal; an anti-stick coating reduces friction and gumming.

DeWalt 7-1/4 in. Precision Trim Miter Saw Blade Review

A compact trim blade that punches above its size

I put this DeWalt 7-1/4-in trim blade on a compact miter saw I keep for punch-list work and small-room trim. My priorities with a blade this size are simple: clean crosscuts in MDF and softwood moldings, predictable feed on a light saw head, and accuracy that doesn’t evaporate when I swing into a compound miter. After a couple of weeks of base, casing, and some plywood tasks, this blade delivered the sort of consistent, “don’t-think-about-it” performance I want from a finish setup.

Setup and build features

Out of the sleeve, the blade looked the part of a purpose-built finishing tool: laser-cut plate, micro‑grain carbide teeth, and a very thin 0.063-in kerf. The 5/8-in arbor fit snugly on my saw, and the plate ran true without noticeable runout. DeWalt’s body slots and anti-stick coating are more than cosmetic; the saw spun up with a smooth, soft whir, and I didn’t get the roar or plate flutter you sometimes hear from thinner blades on small saws.

Important basics:

- Diameter: 7-1/4 in

- Teeth: 40

- Hook angle: 7°

- Kerf: 0.063 in

- Max speed: 9000 rpm

- Arbor: 5/8 in

- Intended for: Wood

That 7° hook angle is mild enough for controlled feeding on a miter saw but not so negative that the blade feels sluggish. It’s a good compromise for crosscutting trim and breaking down smaller stock.

Cut quality on trim and hardwood

On primed MDF, finger-jointed pine, and poplar, the blade produced crisp, ready-to-paint ends with very little fuzzing. The face-ground teeth leave a surprisingly polished surface for a 40-tooth count in this diameter, and more importantly, the blade tracks straight through miters without wanting to walk with a firm but reasonable feed rate. Inside and outside miters closed up cleanly with minimal sanding. On poplar and maple shoe molding, the end grain was smooth enough that I reached for a touch of 220 grit mostly out of habit.

In thicker hardwoods—think 5/4 oak stair nosing or dense maple—I could coax smooth crosscuts if I slowed my feed and let the saw do the work. You can overpower a thin-kerf plate in tough stock if you lean on it; this one held its line well relative to its kerf, but the best results came with a light, steady feed and the blade at full speed.

Plywood, veneered panels, and tear-out control

For small plywood parts and cabinet trim, the blade’s face-ground geometry and thin kerf kept splintering in check. On prefinished birch veneer, the show face was very clean, and the back face had the expected trace of fuzz on the exit side. A zero-clearance insert and a backer board eliminated most of that. If you routinely cut veneered panels, you’ll still want your tear-out control habits—zero clearance, steady feed, and, if needed, painter’s tape on the exit line—but this blade makes those steps effective.

Vibration, noise, and feel

A big worry with thin-kerf blades on compact saws is chatter at the start of the cut or mid-stroke. The DeWalt’s body slots do their job: the blade runs quietly, with less ringing than many general-purpose 7-1/4-in blades. That matters on a lightweight saw head, where any vibration can translate into miter faces that don’t close. I had no issues with the work chattering when nibbling thin returns or coping angles—always a good sign that the plate is behaving.

Power draw and speed

At 0.063 in, the kerf is noticeably slimmer than standard trim blades, and I could feel the benefit on a compact saw. The motor stayed up on speed through 1x and 2x softwood, and I didn’t have to preload the cut to avoid bogging. That thinner bite also preserves layout lines. If you’re doing tight reveal work on small moldings, less material removal is helpful for dialing in miters without “growing” gaps.

Durability and maintenance

Micro‑grain carbide buys you edge life, but only if the grind is supported by a stable plate and you keep pitch under control. After a steady run of MDF and painted pine, the anti-stick coating did seem to hold off the worst gumming. I still gave the teeth a quick clean at the end of each day with a pitch remover. After a couple of projects and a few hundred cuts, the edge remained keen, with no shiny flats on the cutting edges. It’s a grind that should take a sharpening later, which is worth doing given the clean finish it produces.

Accuracy on bevels and compound miters

The real test for trim is cutting compound miters and coming back to the same angle hours later. With the blade warmed up, I set a few 38°/52° crown profiles laid flat and the miters stayed consistent. The thin kerf never felt whippy mid-bevel, which is often where cheaper plates give up. If you’ve trued your saw, built a zero-clearance insert, and clamp the work on steep bevels, this blade will reward that setup with repeatable results.

Limitations and best use

No blade is a unicorn. A few practical limits showed up:

- It’s optimized for crosscuts in wood. Don’t expect good results in aluminum or PVC extrusions.

- In very dense hardwoods over 1-1/2 in thick, you need a patient feed. If your work leans heavily into thick exotics, a stouter plate or more teeth may be a better primary blade.

- For rough construction cuts or demolition, this is the wrong tool. Save it for finish work.

Those are not flaws so much as boundaries of the design brief: a thin-kerf, finish-oriented crosscutter for compact miter saws.

Tips to get the most from it

- Use a zero-clearance throat plate and a backer when cutting veneered faces.

- Let the blade reach full speed before entering the work; feed with steady, moderate pressure.

- Clamp small moldings; thin kerf rewards a stable workpiece.

- Keep it clean. A quick de-gum preserves the edge and the anti-stick coating.

- Check your fence and bevel stops—this blade is accurate enough that saw misalignment will be the limiting factor.

Value and alternatives

In the 7-1/4-in category, many blades are adapted from circular saw duty. This one feels purpose-built for a miter saw: a mild hook, thin kerf, and a grind that favors crosscut finish. If you prioritize ultra-glassy cuts on fragile veneers, a higher-tooth-count blade with a more negative hook can eke out a bit more cleanliness at the expense of speed. For general trim, though, the 40T count here strikes an excellent balance of pace and polish.

Recommendation

I recommend this DeWalt 7-1/4-in trim blade for anyone using a compact miter saw for finish work—door and window casing, baseboard, crown returns, picture frames, and small cabinet parts. It combines a very thin kerf with a stable, quiet plate and a tooth geometry that leaves clean, straight cuts in common trim materials. The blade’s anti-stick coating and micro‑grain carbide hold up over multiple projects, and its mild hook angle keeps feeding predictable on light saw heads. The main caveats are typical of its class: ease off in very hard, thick stock and save it for wood, not metals. Within those boundaries, it’s a reliable, accurate, and efficient upgrade that makes a compact miter saw feel like more than a “small job” tool.

Project Ideas

Business

Custom Picture Framing Pop-Up

Offer made-to-order frames at markets or in a small studio. The blade’s clean crosscuts on hardwoods and moldings deliver premium joints fast, letting you upsell to museum-grade frames with splines or inlay. Add on mat cutting and glass fitting for full-service packages.

Precision Trim and Finish Micro-Service

Provide on-call casing, baseboard, and return cuts for homeowners and contractors. The laser-cut blade body and thin kerf yield tight miters and crisp reveals, reducing caulk lines and callbacks. Market as a ‘final 5%’ punch-list specialist.

DIY Kit Production (Frames, Lanterns, Planters)

Manufacture flat-packed kits with perfectly mitred parts and clear instructions. The blade’s low tear-out ensures customer-friendly parts requiring minimal sanding. Sell through Etsy, craft fairs, and local boutiques, offering custom sizes and wood species.

Wholesale Parquet Coasters and Small Decor

Batch-produce geometric coasters, trivets, and wall tiles with tight seams and repeatable dimensions. The thin kerf reduces material waste, improving margins. Brand sets with laser-engraved logos and offer wholesale to cafes, gift shops, and realtors.

Mobile Crown and Return-Cut Service

Partner with painters and remodelers to deliver on-site mitered returns, shoe molding, and stair trim with minimal tear-out. The anti-stick coating keeps cuts smooth in pre-primed and resinous stock, speeding installs and enabling premium ‘no-fill’ finish quality.

Creative

Gallery-Quality Picture Frames

Build hardwood frames with flawless 45° miters and splines. The blade’s face-ground, micro-grain carbide teeth and thin kerf minimize tear-out and gaps on end grain, so joints close up tight and require less sanding and filler. Add contrasting spline keys for strength and a custom look.

Segmented Wood Art/Bowls

Cut repeatable segments (e.g., 12-, 18-, or 24-segment rings) for flat or turned art. The optimized tooth geometry keeps cuts straight and consistent across many pieces, while the anti-stick coating helps maintain smooth feed in resinous woods like cherry or pine.

Shoji-Style Tea-Light Lantern

Create delicate lattice frames and miters that won’t splinter on thin stock. The thin-kerf blade preserves material and the low-vibration body slots help maintain accuracy for tight-fitting joinery and clean intersections that look crisp when backlit.

Parquet Coasters and Wall Mosaic

Produce patterned tiles (herringbone, chevron, hex) by batch-cutting small, precise pieces at 30/45/60°. The reduced vibration keeps tiny parts from chattering, and the clean crosscuts let patterns assemble with near-invisible seams.

Keepsake Boxes with Splined Miters

Make small boxes with perfectly matched grain wraps at the corners. The blade’s smooth crosscut finish reduces sanding on delicate veneers and the thin kerf keeps lids and sides consistent when separating the box lid after glue-up.