Features

- Engineered with cobalt infused tungsten carbide to extend cutting life

- Laser cut vibration dampening slots to minimize heat and noise

- Ideal for dry metal cutting

- Cuts cooler for immediate handling and reduced downtime

- Designed to provide clean cuts and a burr-free finish

- 5/8 in. arbor hole

- 8 in. diameter

- Cermet tipped for longer life and increased wear resistance

- Hardened steel body

- Vibration dampening

Specifications

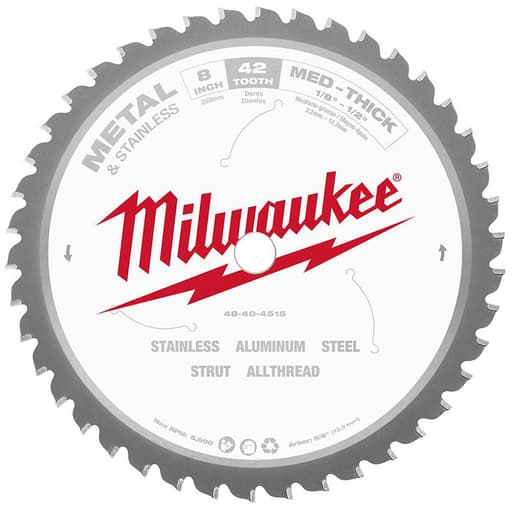

| Application | Metal & Stainless |

| Kerf Thickness | 0.073 in |

| Number Of Teeth | 42 |

| Tooth Grind | Alternate Top Bevel (ATB) |

| Composition | Cermet |

| Hook Angle | 0° |

| Arbor Size | 5/8 in |

| Size | 8 |

| Diameter | 8" |

| Length | 12.7 in |

| Weight | 1 lb |

| Height | 0.2 in |

| Width | 10.4 in |

| Thickness | 1/16" - 1/2" |

| Material Composition | Alloy Steel |

| Material Application | Metal |

Related Tools

Related Articles

Metal circular saw blades are designed for cutting various types of metal and stainless materials. They feature a hand-tensioned, hardened alloy steel body that enhances blade life and cutting quality.

Milwaukee Metal Cutting Circular Saw Blade Review

Engaging with the Milwaukee Metal Cutting Circular Saw Blade, model 48-40-4515, has been an enlightening experience showcasing the combination of engineering prowess and practical performance. This particular blade is designed for metal cutting applications, and it certainly lives up to its reputation for quality and efficiency.

Design and Build Quality

One of the first things that struck me about this blade is its robust construction. Milwaukee has engineered the blade with a cobalt-infused tungsten carbide composition, a choice that immediately signals durability and long-term use. The cobalt infusion not only extends the life of the blade but also ensures it maintains sharpness over extended periods of heavy use. This is particularly beneficial for professionals who rely on consistent performance day in and day out.

The blade's body is made from hardened alloy steel, which provides an additional layer of robustness. This hardened steel is hand-tensioned to reduce the risk of warping or bending, a crucial feature when cutting through tough metals. Additionally, the blade incorporates laser-cut vibration dampening slots, a thoughtful design element that minimizes both heat and noise during operation. This not only makes for a more comfortable cutting experience but also helps in maintaining the integrity of the blade over time.

Cutting Performance

When it comes to cutting performance, the 48-40-4515 does not disappoint. The blade is designed for dry metal cutting, which is a significant benefit as it eliminates the need for messy lubricants or coolants. One of the standout features is its ability to cut cooler compared to other metal cutting blades. This cooler cutting reduces the chance of heat-induced warping and allows for immediate handling of cut materials, significantly reducing downtime.

The blade's 42 teeth, with an Alternate Top Bevel (ATB) tooth grind, ensure clean and precise cuts. The ATB grind is known for its ability to produce sharp and burr-free edges, which is essential when working with metal to avoid additional filing or grinding. I found that the blade handled various metals, including stainless steel, with ease, maintaining a consistent cutting speed without bogging down.

Versatility and Usability

The versatility of this blade is another aspect worth highlighting. With an 8-inch diameter and a 5/8-inch arbor hole, it fits a wide range of circular saws, making it a flexible addition to any toolkit. The blade's 0° hook angle also aids in making smooth, controlled cuts, reducing the likelihood of kickback and improving safety during use.

One of the key features that enhance usability is the blade's cermet-tipped teeth. Cermet, a composite material composed of ceramic and metallic materials, offers superior wear resistance. This means that the blade maintains its sharpness longer, even under rigorous use, which is a significant advantage for professionals who need reliable tools.

Practical Applications

In practical applications, the Milwaukee Metal Cutting Circular Saw Blade excels. I used it for dismantling various metal structures, including conveyor systems and metal piping. The blade cut through these materials like a hot knife through butter, making the task significantly easier and faster. The clean cuts also meant that there was minimal need for post-cut finishing, saving both time and effort.

Another application where the blade shined was in fabricating metal parts. The precise cuts allowed for tight tolerances, which is crucial in fabrication work. The reduced heat generation during cutting was particularly beneficial in this context, as it prevented the metal from becoming too hot to handle immediately.

Value for Money

Given its performance and durability, the Milwaukee Metal Cutting Circular Saw Blade offers excellent value for money. While it might be priced slightly higher than some generic blades, the investment is justified by the blade's extended lifespan and consistent performance. The time saved on frequent blade changes and the superior cut quality make it a cost-effective choice in the long run.

Final Thoughts

The Milwaukee Metal Cutting Circular Saw Blade, model 48-40-4515, is a testament to Milwaukee's commitment to quality and innovation. Its cobalt-infused tungsten carbide teeth, hardened alloy steel body, and laser-cut vibration dampening slots all contribute to a blade that is both durable and efficient. The blade's ability to cut cooler and produce clean, burr-free edges enhances its practicality and usability across a range of metal cutting applications.

For anyone in need of a reliable and high-performing metal cutting blade, I would highly recommend the Milwaukee 48-40-4515. Its robust construction, precise cutting capability, and extended lifespan make it a valuable addition to any professional's toolkit. Whether you are dismantling metal structures or fabricating new parts, this blade is designed to deliver superior performance consistently.

Project Ideas

Business

Custom Metal Fabrication Service

Start a custom metal fabrication business, offering services to clients who need precise metal cutting for various projects, ranging from construction to artistic endeavors. Provide tailored solutions to meet specific client needs.

Metal Signage Business

Launch a business focused on creating high-quality, custom metal signs for businesses, homes, and events. Offer a range of styles and finishes to cater to different markets and preferences.

Metal Furniture Manufacturing

Establish a metal furniture manufacturing company that produces durable, stylish, and functional pieces. Target both residential and commercial markets, showcasing the strength and aesthetic appeal of metal furniture.

Metal Art and Decor Shop

Open a retail shop or online store specializing in metal art and decor items. Curate a collection of unique, handcrafted pieces created using the metal cutting circular saw blade, appealing to art enthusiasts and interior decorators.

Automotive Customization Service

Offer a service that provides custom metal parts and modifications for vehicles. Use the saw blade to create precise, high-quality components for automotive enthusiasts looking to personalize their cars or motorcycles.

Creative

Custom Metal Art Sculptures

Use the metal cutting circular saw blade to create intricate metal sculptures. Design and cut various shapes and forms from metal sheets, then assemble and weld them together to produce unique art pieces for home decor or public installations.

Metal Wall Art Panels

Create decorative metal wall panels with detailed designs. Use the saw blade to cut patterns, geometric shapes, or even custom images into metal sheets. These panels can be used as statement pieces in homes or commercial spaces.

Personalized Metal Signs

Design and cut personalized signs for homes, businesses, or events. Offer custom text and shapes, allowing clients to create unique signage that reflects their style or brand.

Functional Metal Furniture

Craft functional pieces of furniture such as tables, chairs, and shelves. Use the saw blade to precisely cut metal components, which can then be welded and assembled into modern, industrial-style furniture.

Metal Jewelry and Accessories

Design and produce metal jewelry and accessories like bracelets, necklaces, and belt buckles. The precision of the saw blade allows for detailed and intricate designs, making each piece unique.