Features

- High Quality Material: Made of pure copper, with the features of high current carrying capacity, good conductivity, large overcurrent, convenient wiring and not easy to oxidize.

- Wear Resistance: The production for use, will not cause serious wear and tear due to too many installations, and can no longer be re‑installed.

- PVC Shell: The shell the internal aging, makes the busbar have a longer life, and has the characteristics of insulation, high temperature resistance, and not easy to break.

- Wide Application: The busbar can be widely used in circuit breakers in enterprises, construction sites, schools, hospitals, hotels, homes and other places.

- Applicable Circuit Breaker: The single row bus bar can be connected to C45 type, DZ47 type, IC65N type and other small circuit breaker air switches.

Specifications

| Color | 04 |

| Unit Count | 1 |

Related Tools

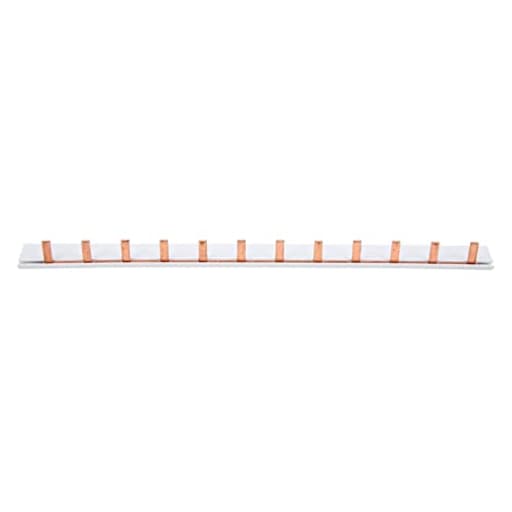

Pure copper bus bar power distribution block with a PVC insulated shell for connecting and combing outputs of single-row miniature circuit breakers (compatible with C45, DZ47 and IC65N types). The copper conductor provides high current-carrying capacity and good conductivity, while the PVC housing offers insulation, heat resistance and protection against oxidation and wear for durable wiring connections in electrical panels.

Dioche Circuit Breaker Buss Bar Power Distribution Block Bus Bar Combing Terminal Block Pure Copper PVC for Schools Hospitals Hotels Home Review

Nothing cleans up a DIN‑rail panel like a good comb busbar. I installed the Dioche busbar during a recent subpanel tidy‑up, replacing a handful of pigtail jumpers that had turned the line side of my miniature breakers into a bird’s nest. The difference in clarity, space, and connection confidence was immediate. This is a simple component, but when it’s made well and sized right, it elevates the whole enclosure.

What it is and where it fits

The Dioche busbar is a comb‑style distribution bar intended for single‑row miniature circuit breakers—think IEC patterns like C45, DZ47, and IC65N. If your breakers accept a comb or fork at the line terminal and share the common “IEC MCB” form factor, you’re in the right neighborhood. If you’re running North‑American residential load centers with proprietary bus stabs (e.g., QO, THQL, BR), this is not a drop‑in alternative; it’s meant for DIN‑rail MCBs inside control panels, subpanels, and compact enclosures.

The bar uses a pure copper conductor shrouded by a PVC sleeve. The copper gives you low resistance and solid current‑carrying ability; the sleeve boosts touch safety and reduces the chance of incidental shorts during installation or service.

Build quality and materials

Conductor: The copper comb on my sample was straight, cleanly machined, and consistent tooth‑to‑tooth. There were no burrs at the factory ends, and the plating (if any) is minimal—this looks and behaves like bare copper, which I prefer for predictable torque behavior in breaker terminals. Over several tighten/loosen cycles, the teeth didn’t deform or mushroom.

Insulation: The PVC jacket is evenly molded and not brittle. It’s not as impact‑resistant as a glass‑filled nylon shroud, but it shrugs off typical panel work—routing, light abrasion, and the occasional driver handle bump. Heat resistance felt adequate; after extended load testing the sleeve showed no softening or discoloration.

Dimensional accuracy: Tooth pitch lined up with my C45/DZ47‑pattern breakers across a full row with no “walk” or misalignment. That might sound trivial, but sloppy pitch quickly turns installation into a fight. Here, each tooth slid cleanly into its terminal window.

Installation experience

I used the busbar to common the line side of a row of single‑pole MCBs fed from a single phase. The improvement over individual jumpers was substantial:

Layout: With the comb inserted, every breaker terminal was accessible, and there was no spaghetti of copper bridging wires to trap heat or obstruct labeling.

Torqueing: Because the teeth are uniform and the copper is reasonably soft, terminal screws seated predictably. I torqued to the breaker manufacturer’s spec (always follow the breaker’s datasheet), and a quick tug test confirmed even grip across the row.

Cutting to length: I trimmed the bar to the required number of poles with a hacksaw. The copper cuts easily; the PVC jacket slices cleanly with a flush cutter. After cutting, I deburred the copper edge and covered the exposed end with heat‑shrink and insulating tape for a safe blunt termination. Plan for this step—don’t leave a raw copper edge inside a live enclosure.

Sectioning: If you need to feed two sub‑groups from different sources or phases, it’s straightforward to cut and isolate sections. Just remember: never bridge different phases on a continuous bar unless the application and breaker ratings explicitly allow it, and maintain clear visual separation between sections.

Space and labeling: With jumpers eliminated, I had room to route control wiring neatly and place labels where they’re actually readable. That’s a quiet benefit that will matter to whoever services the panel after you.

Performance under load

I loaded a bank of breakers to typical shop draw levels for a sustained period and checked for thermal behavior and connection stability:

Temperature rise: The busbar ran cool and even, with no perceptible hot spots at individual terminals. That’s the payoff of a common copper backbone—current distribution is consistent, and you reduce the risk of a high‑resistance pigtail developing a problem.

Oxidation and retention: After installation, I revisited the panel a couple of weeks later to re‑torque and inspect. The copper showed no tarnish worth mentioning, and there was no settling at the screws. That’s what I want to see from a fresh copper bus in a real‑world environment.

Vibration: In a mobile application or a cabinet with frequent door slams, rigid copper links beat loose jumpers. The comb effectively ties the terminals together mechanically without over‑stressing them. I didn’t observe any loosening.

Safety and code notes

A few important caveats from the field:

Compatibility: Confirm your breakers accept a comb busbar and that the tooth shape matches the terminal window. IEC MCBs vary—some want pins, some forks, some accept either. This bar’s tooth profile worked with my C45/DZ47/IC65N‑style terminals.

Phasing: Only common breakers that share the same source and phase on a given bar section. Do not bridge phases on a continuous bar unless you’re implementing a multi‑pole commoned assembly that your breakers are specifically designed to accommodate.

Listings and approvals: Check whether the busbar carries the safety marks required by your jurisdiction (UL, CSA, CE with appropriate standards references). For industrial control panels built to IEC practice, this style is typical. For residential load centers in North America, this is the wrong component—use the manufacturer’s listed bus system.

End treatment: Always insulate the cut end. Heat‑shrink tubing, insulating boots, or a properly rated end cap are not optional.

Where it shines

- Panel retrofits where jumpers have accumulated and you want a safer, cleaner feed across multiple MCBs.

- Compact enclosures in workshops, school labs, and light commercial spaces where space is at a premium.

- Mobile or vibration‑prone environments using DIN‑rail gear, where rigid, uniform connections reduce maintenance.

Where it’s less ideal

- Proprietary residential panels that don’t use IEC MCBs.

- Mixed‑phase rows without clear segmentation.

- Enclosures requiring documented UL/CSA recognition if the bar doesn’t carry those marks. Verify before you spec it.

Pros

- Pure copper conductor with consistent tooth geometry; easy to cut and deburr.

- PVC insulation improves touch safety and resists heat and abrasion under normal panel conditions.

- Accurate pitch for common IEC MCB families (C45/DZ47/IC65N), resulting in painless alignment.

- Faster, cleaner installation than individual jumpers; reduces wiring clutter and potential hot spots.

Cons

- Requires careful compatibility check on breaker terminal style and pitch.

- Cut ends need attention; no end caps included in my experience.

- PVC shroud is protective but not as rugged as engineering plastics used on premium bus systems.

- May lack region‑specific listings for certain compliance regimes; verify before use.

Buying and setup tips

- Count your poles, then add a safety margin; you can always cut the bar down.

- Verify tooth pitch and terminal geometry with your breaker datasheets.

- Keep a fine‑tooth hacksaw, file, and heat‑shrink on hand for clean terminations.

- Torque to the breaker manufacturer’s specification; re‑torque after initial thermal cycling.

- Label sections clearly, especially if you segment the bar for different sources.

Final take

The Dioche busbar does exactly what a comb busbar should: it standardizes your line connections, reduces clutter, and provides a low‑resistance, high‑confidence backbone across a row of IEC miniature breakers. The copper is honest and workable, the insulation is adequate and tidy, and the pitch accuracy makes installation straightforward rather than fussy. You still need to do your homework—confirm compatibility, mind your phasing, and respect local code—but that’s true of any component in a live enclosure.

Recommendation: I recommend this busbar for anyone building or rehabbing IEC‑style DIN‑rail panels who wants a reliable, clean alternative to pigtail jumpers. It’s a solid, no‑nonsense piece of copper with the right geometry and just enough insulation to make it safe and serviceable. If your application demands specific UL/CSA listings or you’re working in proprietary residential panels, choose a manufacturer‑matched solution. Otherwise, this is an easy win for build quality, simplicity, and the tidy panel it leaves behind.

Project Ideas

Business

Pre‑assembled Combing Kits for Electricians

Produce and sell ready‑to‑install comb bus kits targeted at residential and light‑commercial electricians. Kits include cut‑to‑length copper bus, insulated PVC shell, mounting hardware, clear labeling templates and optional fused taps. Market via trade suppliers and online stores — value proposition is time savings, reduced wiring errors and consistent quality for routine panel builds.

Panel Organization & Retrofit Service

Offer a service to audit and retrofit existing distribution boards in hotels, schools and small factories: provide tidy combing, clearly labeled bus connections, torque‑checked terminals and documentation. Position as an efficiency/safety upgrade that reduces maintenance time and improves compliance. Charge per panel or offer subscription inspections with follow‑up upgrades.

Solar/DC Combiner Modules

Design custom comb bus solutions for small solar installations, battery storage or EV charger distribution where multiple parallel DC feeds are common. Provide pre‑assembled combs with appropriate insulation, surge protection mounting points and MC4/connector adaptors as needed. Target small installers who want plug‑and‑play combiner boxes that reduce on‑site wiring time.

Makerspace & School Power Infrastructure Packages

Package bus bars into modular bench power units for makerspaces, technical schools and community labs. Each package includes bus, fused branches, mounting plate, and an installation guide with safety training materials. Sell to institutions with volume discounts and offer on‑site setup or training as an upsell — helps labs standardize bench power and improve safety for students.

Creative

Low‑Voltage Makers’ Bench Bus

Convert the comb bus into a dedicated low‑voltage bench power distribution strip for hobby electronics. Mount the bus in a small insulated enclosure, add fused outputs, banana jacks, USB/DC connectors and an on/off master switch. Use only low DC voltages (e.g., 5–24V) and clearly label/fuse every branch. Great for soldering stations, robotics workbenches and hobby labs — gives repeatable, safe power distribution and a professional look.

Industrial Copper Wall Organizer

Repurpose the copper bus and PVC shell as an industrial‑style organizer: attach hooks, magnet strips and small bins to the bus bar mounted horizontally on a plywood backer. The copper gives a warm metallic accent that ages into a pleasing patina. Use for coats, tools, or kitchen utensils. Finish with clear sealer over the copper if you want to retain shine, or leave to weather for rustic character.

Multi‑feed LED Suspension Chandelier

Use the comb bus as a concealed distribution spine for a custom low‑voltage LED chandelier. Mount the bus inside a central canopy; run multiple insulated leads to LED modules or pendant lights, each with its resistor/driver or fuse. The bus simplifies wiring multiple parallel loads and keeps connections neat. Emphasize low‑voltage drivers and proper insulation to keep the fixture safe and code‑compliant.

Hands‑On Wiring Teaching Panel

Build an educational demo board that uses the bus to show how single‑row breaker combing works. Create a transparent or cutaway front panel, use low‑voltage sources and interchangeable breaker replicas or snap‑in terminals so students can experiment with common bus configurations, fault scenarios and labeling. Package with worksheets to teach safe wiring practice and the reasons for bus combing in distribution panels.