Features

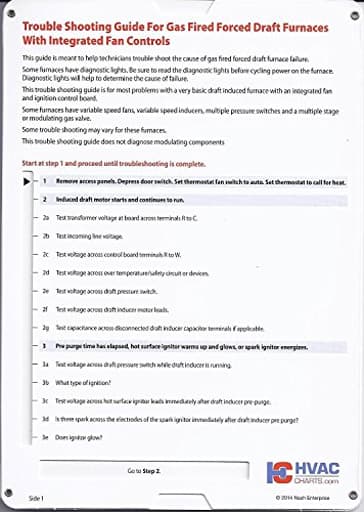

- Step by step instructions for troubleshooting most gas forced air furnaces.

- For use with furnaces with integrated fan controls.

- Helps technicians learn sequence of operation.

- Some troubleshooting may vary for certain brands.

- Does not diagnose modulating components.

Related Tools

A step-by-step repair and troubleshooting guide for gas forced-air furnaces that explains common fault isolation and repair procedures. Intended for furnaces with integrated fan controls, it outlines sequence of operation and typical troubleshooting paths, notes that procedures may vary by manufacturer, and does not cover diagnosis of modulating components.

MFEESYOB Gas Forced Air Furnace Repair and Trouble Shooting Guide Review

Why I reached for this guide

A no-heat call on a cold morning is the wrong time to be scrolling through PDFs or guessing at a furnace’s logic. I picked up this furnace troubleshooting guide to have a simple, reliable way to walk through the sequence of operation on standard gas forced-air units with integrated fan controls. After several service calls and a couple of controlled tests on my bench setup, I found myself using the guide not just as a reminder of steps I already know, but as a way to structure diagnostics so I don’t skip something obvious.

What the guide actually covers

This is a focused, step-by-step reference for conventional, non-communicating furnaces that use integrated fan control boards. It lays out:

- The standard sequence of operation (thermostat call → inducer → pressure switch → ignition → gas valve → flame sense → blower).

- Where each safety and control component plays its role, and how faults in that stage typically present.

- Common, repeatable checks with a meter and manometer.

- Typical variations you may encounter between brands.

It does not attempt to diagnose modulating or communicating systems, and it doesn’t try to be an encyclopedic brand-by-brand manual. Think of it as a structured flow through the fundamentals that apply across most single-stage and many two-stage furnaces, provided they’re not using fully modulating or proprietary communicating controls.

How it worked in the field

The first time I used the guide in earnest, I had a 90% condensing furnace that would light, run for 30–60 seconds, then drop out and retry. The guide had me slow down and follow the sequence instead of jumping straight to the gas valve. Starting at the call for heat, I checked the inducer and verified negative pressure. The next step highlighted the pressure switch and condensate pathway. A quick check of the trap showed a partial blockage; clearing the trap stabilized the pressure switch, and the nuisance cycling stopped. Nothing complex—just a clean, logical path that kept me disciplined.

Another case was a classic “no-heat, inducer runs, no flame” scenario. The guide’s ignition stage spelled out checks I already make: verify 120V to the hot surface igniter, inspect for cracks, confirm current draw, measure 24VAC to the gas valve at the right point in the sequence, and verify flame rectification once ignition occurs. In this case, the igniter had no continuity, and replacing it restored heat. Again, basic stuff—but having the steps laid out prevents tunnel vision.

Where the guide adds value is in bridging symptoms to the sequence without assuming brand-specific knowledge. It points you to read board fault codes, verify W and C at the control, and then decide whether you’re looking at a low-voltage control problem, a safety open, or a combustion/airflow issue. If you’ve ever chased a limit-trip that turned out to be a filthy filter and closed registers, you’ll appreciate the reminder to check external airflow restrictions before diving into component replacement.

Strengths that stood out

- Clear sequence of operation: The backbone of the guide is its orderly progression through the furnace’s logic. If you teach apprentices, it doubles as a structured lesson plan for how a furnace thinks.

- Practical test points: It doesn’t get lost in theory. It points you to the terminals you’ll actually measure (W/C, R/W voltage during a call, gas valve coil voltage, pressure switch continuity) and the typical timing delays you can expect.

- Works across brands (within limits): Because it’s rooted in fundamentals, it translates across most integrated control boards. You may need to adapt for different fault code charts, but you won’t be left guessing what step comes next.

- Good at ruling out: The flow encourages elimination. If you can prove the board is sending 120V to the igniter and 24V to the valve at the right times, you’ve narrowed the field considerably.

Where it comes up short

- No coverage of modulating or communicating systems: If you spend most of your time with fully modulating furnaces, communicating thermostats, or proprietary OEM diagnostics, this guide won’t meet all your needs. You’ll want brand-specific literature for ECM module diagnostics, data bus issues, or valve modulation logic.

- Generic fault-code handling: It reminds you to check the board’s blink codes, but you’ll still need the furnace’s service label or technical sheet to interpret brand-specific patterns.

- Assumes access to basic tools: It’s written with the expectation that you have (and know how to use) a multimeter, a manometer (for pressure switch validation), and a basic understanding of line and low-voltage circuits. It’s not a substitute for electrical safety training.

- A few edge cases missing: In higher-efficiency units, subtle issues like intake/exhaust termination icing, shared venting interactions, or condensate pump interlocks don’t get explicit treatment. The fundamentals still help you find them, but you won’t get a tailored path for those scenarios.

Tips for getting the most out of it

- Pair it with the unit’s wiring diagram and fault code chart. The combination is much more powerful than either alone.

- Read through the entire sequence once before testing. Having the big picture in mind helps you avoid unnecessary parts swapping.

- Take notes as you go. Recording voltages and continuity checks at each stage lets you backtrack cleanly if the first hypothesis doesn’t pan out.

- Confirm airflow and combustion air early. The guide nudges you in that direction, but make it a habit to check filters, returns, and terminations upfront.

- Respect lockout behavior. Give the control board time to reset, or manually reset if needed, when moving between stages; otherwise you can misinterpret what the board is doing.

Who it’s best for

- Technicians and apprentices working mostly on legacy and conventional non-communicating furnaces. If your bread and butter is 80% and 90% furnaces with integrated boards, this fits neatly in your bag.

- Facility maintenance staff who need a structured approach. The sequence-of-operation framing helps non-specialists avoid common missteps, provided they’re comfortable with basic measurements.

- Experienced pros as a sanity check. Even if you know the steps by heart, having a reference reduces the chance of skipping a simple check on a busy day.

If you primarily service modern, fully modulating or communicating systems, you’ll want to supplement this with brand-specific diagnostic guides. The fundamentals still apply, but you’ll outgrow the guide’s scope quickly when dealing with communication bus faults, ECM module issues, or adaptive controls.

What I’d like to see improved

- A brief appendix on common ECM blower checks and safe testing practices would round this out for a broader slice of the market.

- More explicit notes on two-stage operation nuances (pressure switch configurations, staging delays) would help intermediate techs.

- A quick-reference chart mapping generic symptoms to likely causes with test points could speed triage even further.

None of these are deal-breakers; they’re wish-list items that would elevate a solid reference to an even more comprehensive one.

Bottom line

This guide earns a place in my truck because it enforces a disciplined, efficient diagnostic process on standard gas forced-air furnaces. It doesn’t try to be everything to everyone, and that’s part of its strength: it focuses on integrated fan control systems, teaches the real-world sequence of operation, and walks you through testable checkpoints that lead to answers without guesswork.

Recommendation: I recommend this guide for technicians, apprentices, and maintenance pros who routinely work on non-communicating furnaces and want a clear, step-by-step method to isolate faults. It’s especially useful as a training aid and as a guardrail against skipping fundamentals under time pressure. If your workload is dominated by modulating or communicating equipment, treat this as a supplemental reference and lean on brand-specific documentation for those systems.

Project Ideas

Business

Paid Online Course & Certification Prep

Turn the guide into a modular online course with video walk-throughs, quizzes, and a downloadable checklist. Offer tiered pricing (basic reference, pro course with lab exercises, and a paid certificate) to attract apprentices, continuing-education students and company training programs.

Subscription Troubleshooting App

Develop a mobile/web app that implements the guide as an interactive decision tree: searchable faults, step timers, photo capture for job records, and push updates when new procedures are added. Monetize via monthly subscriptions for tech teams or premium single-license downloads.

HVAC Technician Starter Kit

Bundle a printed master guide, pocket cards, basic diagnostic tools (manometer, multimeter probes, combustion analyzer checklist), and an access code to online resources into a branded starter kit for apprentices or new hires. Sell kits to HVAC schools, contractor shops, and distributors.

B2B Licensing & OEM Training Content

License the guide's content to HVAC manufacturers, contractor networks and trade schools to integrate into their standard operating procedures and training programs. Offer customization (brand-specific notes, policy overlays) and recurring revenue via update/maintenance contracts.

Creative

Interactive Troubleshooting Flowchart Poster

Design a large, laminated wall poster that translates the guide's step-by-step sequences into a color-coded decision flowchart. Use icons for safety checks, ignition, gas valves and fans so techs can quickly see next steps during a service call; sell smaller foldable versions as shop-ready reference aids.

Pocket Field Guide Cards

Create a set of waterproof, pocket-sized cards (or a flipbook) that condense common fault isolation steps and test points from the guide (e.g., ignition sequence, flame sensing checks, blower timing). Ideal for apprentices and mobile techs — include quick reference schematics and a QR code linking to full procedures.

Hands-on Repair Workshop Series

Use the guide as the syllabus for a hands-on class: build exercises that simulate common faults, timed troubleshooting drills, and sequence-of-operation labs. Package lesson plans, checklists and student workbooks so you can run community workshops or maker-space events teaching practical furnace diagnostics.

Benchtop Diagnostic Training Board

Construct a removable mock-up of a gas forced-air furnace control system (LEDs, relays, switches, simulated sensors) that can be wired to produce common fault modes. Pair it with the guide so trainees can intentionally inject faults and practice the exact step-by-step troubleshooting without working on live equipment.