Features

- OEM Replacement: MHU45 LP, MHU45 NG, MHU50 LP, MHU50 NG, MHU55 LP, MHU55 NG, MHU70 LP, MHU75 LP, MHU75 NG, MHU80 LP, MHU80 NG, MHU125 LP, MHU125 NG

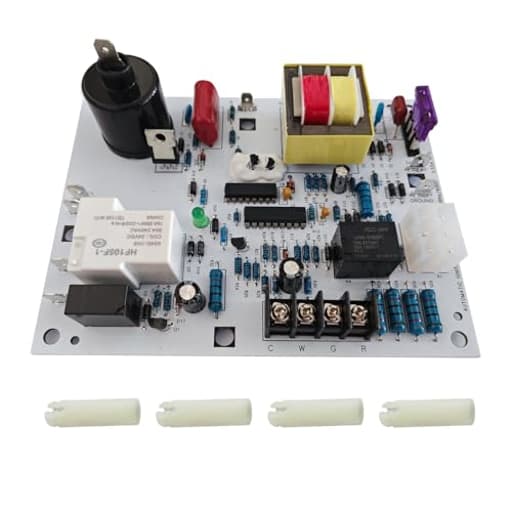

- 60105 Control Board is the newest style 6 Pin control board compatable for all Mr Heat-er, Heat-Star, Big Ma-xx and Ener-co overhead Propane and Natural gas unit heaters under 125,000 BTU

- Control and Command Center: This circuit board acts as the control center, regulating various functions such as ignition, temperature settings, and safety features and providing troubleshooting fault code flashes

- Reliable Performance: 60105 Heater Circuit Board is a crucial component for efficient and reliable operation of your compact overhead furnace and garage heaters

- 60105 Circuit Board is constructed with durable materials and precise engineering. This ensures direct replacement, consistent performance, and longevity for your heating unit

Specifications

| Color | As Shown |

| Unit Count | 1 |

Related Tools

This 6‑pin control board serves as a direct replacement for overhead propane and natural gas forced‑air unit heaters up to 125,000 BTU. It manages ignition, temperature control, and safety interlocks while providing diagnostic fault‑code flashes for troubleshooting. The board is constructed for durable, drop‑in replacement and consistent operation with compatible furnace models.

Aepiraza 60105 Control Board Fit for Mr Heater, Enerco, MHU and HSU Series Overhead Compact Garage and Workshop Natural Gas and Propane Fired Forced Air Furnaces up to 125,000 BTU's Review

Why I Replaced My Heater’s Brain

My garage unit heater chose the first cold snap of the season to quit. The blower ran, but there was no ignition, no flame, and no heat. After checking the thermostat, rollout switch, pressure switch, and gas valve wiring, all signs pointed to a failed control board. I installed the 60105 control board as a drop-in replacement, and it brought the heater back to life on the first try. Here’s how the board performed, what installation was like, and a few practical notes if you’re considering the same fix.

What the 60105 Control Board Does

Think of this as the command center for compact overhead unit heaters that run on natural gas or propane. The 60105 board coordinates ignition, monitors safety interlocks (pressure switch, rollout and limit switches), reads the flame signal, and controls the blower timing. It also includes an onboard LED that flashes fault codes—hugely helpful when a heater refuses to light and you’d rather not guess which safety string is open.

Compatibility is wide for 6‑pin Mr. Heater/Enerco-based units under 125,000 BTU. In my case, I installed it in a Mr. Heater MHU-series natural gas unit. The 6‑pin harness matched, the mounting holes lined up, and no wiring changes were necessary. The board is also intended to work with common models across Mr. Heater, Heat Star, Big Maxx, and Enerco in the MHU/HSU family, including popular sizes like 45k, 50k, 55k, 70/75k, 80k, and 125k BTU units—both LP and NG variants—so long as your heater uses the newer 6‑pin style.

Installation Experience

My swap took about 20–30 minutes at a comfortable pace.

- I locked out the breaker and shut the service switch before opening the heater cabinet.

- I took clear photos of the original board and wiring (highly recommended) to have a reference for each terminal and harness.

- The old board came out with a couple of screws and standoffs. The new board’s mounting pattern matched perfectly. No drilling or adapter brackets required.

- The 6‑pin main harness pressed firmly onto the new board, and the individual spade connectors (gas valve, blower, flame sensor lead, limit string) were clearly labeled. Transferring one wire at a time avoided mix-ups.

- Before powering up, I checked all push-on terminals for a positive seat and made sure no wires were near the heat exchanger or any moving parts.

If you’re new to this, you won’t need special tools beyond a nut driver, a small screwdriver, and a flashlight. You’re not opening gas lines for this job, but do make sure the gas valve wiring is returned exactly as found. A wiring diagram on the heater panel is a good cross-check if your photos are unclear.

First Fire and Operation

On first power-up with a heat call, the sequence sounded exactly like a healthy direct-spark system should:

- A short pre-purge by the blower

- The distinct click of the gas valve with ignition

- A quick flame establishment

- Smooth transition to steady burn with the blower ramping to heat the space

The heater recovered the garage temperature quickly and cycled normally afterward. I watched several cycles across an evening of shop work and never saw a hiccup or an unexpected lockout.

The diagnostic LED is a true time-saver. I induced one test by leaving the thermostat off briefly with power on, just to confirm status behavior; the board’s LED made it clear when it was in standby and when a heat call was present. I didn’t need to trigger specific faults, but the printed fault-code key and visible LED give confidence for future troubleshooting if a pressure switch tube cracks or a rollout switch trips.

Build Quality and Design

While I can’t speak to lab specs, the board I installed looked and felt well made:

- Clean soldering with no cold joints visible through the coating

- Solid standoffs that didn’t flex the board during mounting

- Clearly printed terminal labels and an easy-to-read fault legend near the LED

- Firm, positive connection on the 6‑pin harness

Relays click audibly (as expected), but there’s nothing unusually loud or concerning about the operation. The board ran cool and stable during multi-hour cycles in a chilly garage.

Compatibility and Fit Notes

A few quick checks to confirm before ordering:

- Pin style: This board is the newer 6‑pin format. If your existing board uses a different connector style or pin count, verify you’re not dealing with an earlier or unrelated control scheme.

- Heater family: It’s intended for compact overhead forced-air unit heaters (Mr. Heater, Heat Star, Big Maxx, Enerco) under 125,000 BTU. It is not for radiant heaters or wall furnaces with different ignition controls.

- Fuel type: Works with both LP and NG variants in the compatible series. The board itself doesn’t care which fuel you run; the burner orifices and gas valve do.

- Model check: If your model number is one of the common MHU/HSU sizes (e.g., 45/50/55/70/75/80/125), you’re likely in the clear. Still, confirm the 60105 designation in your manual or parts list.

Tips From the Install

- Photograph everything: A few phone pictures before pulling wires is better than guessing later.

- Inspect the pressure switch tubing: If it’s brittle or cracked, fix it now. Control boards often get blamed for pressure switch faults.

- Clean ground and flame rod: Poor flame sensing can mimic a bad board. A quick check while you’re in there can save future headaches.

- Mind the standoffs: Don’t overtighten. Snug is enough to keep the board flat and supported.

- Label loose spades: If your heater has extra accessory wires, label them before removal.

Performance Over Time

After weeks of on-and-off heating in an uninsulated garage—morning warm-ups and evening shutdowns—the board has remained stable. Ignition is repeatable, blower timing feels consistent, and the unit holds temperature as expected with a basic single-stage thermostat. I haven’t experienced nuisance lockouts or random resets.

I do like that this board behaves predictably during short cycling. If the thermostat is toggled quickly, it handles the transition gracefully and resumes a normal sequence without confusion. That’s not always the case with older, failing controls.

Who It’s For (and Who It’s Not)

- Ideal for: Owners of compatible Mr. Heater/Enerco-based unit heaters who’ve diagnosed a failed control board, or those experiencing intermittent ignition and have ruled out sensors, switches, and gas valve issues.

- Not ideal for: Anyone with a mismatched pin configuration, radiant heaters, or high-BTU commercial units outside the listed range. Also, if you’re not comfortable working inside a gas appliance, it’s worth calling a pro—incorrect wiring can defeat safety circuits.

Pros and Cons

Pros

- True drop-in replacement on compatible 6‑pin units

- Clear terminal labels and onboard fault-code LED

- Stable ignition and blower control with predictable sequencing

- Solid build quality and firm connector engagement

- Works across NG and LP variants in the supported series

Cons

- Only fits the newer 6‑pin ecosystem; older boards aren’t covered

- No frills beyond what you need (a plus for reliability, but not “smart” features if you’re looking for them)

- If safety faults exist in the furnace (e.g., blocked vent, failed switches), a new board won’t magically solve them—diagnosis still matters

Bottom Line Recommendation

I recommend the 60105 control board for anyone maintaining a compatible Mr. Heater/Enerco-style unit heater under 125,000 BTU. It restored my heater instantly, installed without wiring gymnastics, and offers straightforward diagnostics for future troubleshooting. The board does exactly what a control board should: manage ignition and safeties reliably without fuss. If your existing board has failed and you’ve confirmed compatibility and basic system health, this is a dependable, practical replacement that gets heat back into the shop with minimal downtime.

Project Ideas

Business

Niche Replacement Parts E‑commerce

Start an online store specializing in hard-to-find OEM replacement control boards (like the 60105) and compatible parts for compact overhead unit heaters. Offer detailed compatibility charts, wiring diagrams, troubleshooting guides, and video installation tutorials to reduce returns and build trust with DIYers and independent HVAC shops.

Mobile Board Replacement & Safety Inspection Service

Offer a service that dispatches to garages and small workshops to diagnose heater failures, replace control boards, test safety interlocks, and certify safe operation. Package fixed-price replacements, seasonal tune-ups, and emergency callouts. Add a digital checklist and photos on every job to upsell maintenance agreements.

HVAC Technician Workshops & Certification

Run paid hands-on classes for independent contractors and DIYers showing how to read fault codes, install the 60105 board, wire thermostats and interlocks, and perform safe start-up procedures. Provide students with a take-home cheat-sheet, problem-simulation kits, and optional bulk-purchase discounts on replacement boards.

Refurbish, Test & Warranty Resale

Collect failed or surplus 60105 boards, perform component-level diagnostics and repairs, then test them on bench rigs and resell with a limited warranty. Offer a lower-cost alternative to new OEM boards and add value with documented test logs, return shipping, and a quick-turn inventory for contractors who need same-day parts.

Creative

Steampunk Control-Board Clock

Turn the 60105 control board into the centerpiece of a wall clock or tabletop sculpture. Mount the board on a brass or reclaimed-wood backplate, add vintage gauge faces for temperature and status, repurpose the LED fault-code flashes as a visual seconds indicator, and surround with pipes/valves for a steampunk aesthetic. Important: deactivate and pot the board or remove powered components so the artwork is safe to handle.

HVAC Learning Bench

Build a compact bench-top teaching module that uses a 60105 board wired to simulated components (mock blower motor, LED gas valve indicators, thermostat input, and labeled connectors). Use it for hands-on demonstrations of ignition sequences, safety interlocks, and fault-code troubleshooting. Include clear labels, a removable cover, and an isolation transformer so students can safely practice diagnostics without live gas.

Interactive Fault-Code Lamp Sculpture

Create an interactive lamp that visually displays the board's diagnostic flash patterns as an ambient light show. Map different fault-code flash sequences to color/brightness changes or to separate LED rings. The control board becomes both an art element and an educational toy about how heaters communicate errors. As with all repurposing, ensure the board is unpowered or safely enclosed from users.

Showpiece Demo Heater (Trade Show Prop)

Assemble a non-powered demo of a compact overhead heater using the 60105 board mounted with clear acrylic housings and labeled components to show how a furnace works. Use this prop at trade shows or in a showroom to explain ignition, thermostats, and safety interlocks visually. Design it so gas/electric lines are disabled and observers can safely view moving parts and diagnostic LEDs.