Features

- High-alloy steel (HAS) construction

- 20 TPI (fine/regular cut)

- 5.75 in tooth length

- Sold as a single blade

- Designed for use with power handsaws

Specifications

| Material | High-alloy steel (HAS) |

| Length Of Teeth (In) | 5.75 |

| Tooth Pitch (Tpi) | 20 |

| Pack Quantity | 1 |

| Type | Power handsaw blade |

Related Tools

Related Articles

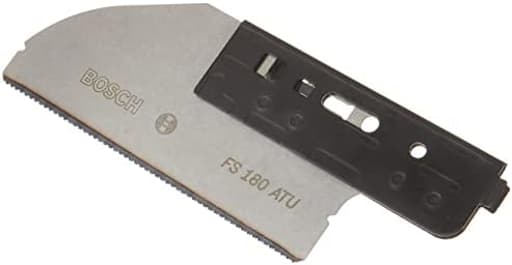

Power handsaw blade constructed from high-alloy steel. Designed for use in power handsaws to produce a fine/regular cut (20 TPI). Tooth length is 5.75 inches. Sold as a single blade.

Bosch Power Handsaw Blade Review

Why I reached for this blade

A fine-tooth blade can make or break a finish cut. I picked up the Bosch blade specifically to tidy up some maple shoe molding and PVC trim on a renovation, expecting clean edges and predictable handling from a compact power handsaw. After a few days of mixed-material work, this blade earned a spot in my kit for fine cuts—though it isn’t the right choice for every task.

Build and design

The blade uses a high-alloy steel body, which keeps it light and reasonably stiff without being brittle. At 20 TPI, the tooth geometry is tuned for fine or “regular” cuts rather than fast stock removal. The tooth length is 5.75 inches, giving you enough usable bite for most compact power handsaws. It’s sold as a single blade, which matters if you’re budgeting for a lot of cuts.

High-alloy steel is a solid pick for wood and plastics. It won’t last as long as bi-metal in abusive conditions or around nails, but it sharpens easily and behaves well with controlled feed pressure. The tooth set is modest, producing a narrower kerf and reducing tear‑out on thin stock.

Setup and compatibility

Installation was uneventful. The spine and mounting end were straight and true, and the blade seated squarely without shimming. In my power handsaw, the full 5.75 inches of teeth engaged with room to spare, which helped maintain a consistent stroke. If your saw has a shorter stroke or tight shroud, double-check that you can expose enough teeth to keep the cut clean and cool.

Because it’s a single blade, I recommend picking up at least one spare if you’re heading into a long day of cutting. Fine teeth are excellent for finish quality but more susceptible to dulling if you push too hard or hit a hidden fastener.

Cutting performance

- Softwoods (pine, fir): Clean crosscuts with minimal fuzzing. Rips were straight but slow; this isn’t a speed blade.

- Hardwoods (maple, oak, cherry): Very good edge quality on crosscuts. Slight burn risk if you pause mid-cut in dense stock—keep the blade moving and let the teeth do the work.

- Sheet goods (plywood, melamine, laminate): This is where the blade shines. Tear-out was impressively low on prefinished plywood, and melamine showed only light micro-chipping along the exit edge.

- Plastics (PVC, ABS): Smooth cuts with no melting at moderate stroke speed. If you notice heat buildup, dial back feed pressure and increase stroke speed slightly.

- Composites (MDF): Clean, but the abrasive binder will dull the teeth faster than solid wood. Plan accordingly.

I avoided cutting metal with it. At 20 TPI, you might be tempted to nibble thin non-ferrous stock, but high-alloy steel won’t hold up like bi-metal, and the tooth profile isn’t optimized for metal chips.

Precision and surface finish

The best part of this blade is the finish quality. On maple trim, the cut surface came off the saw ready for a light sanding pass—no torn fibers at the trailing edge. The narrow kerf makes it easy to creep up on a line and maintain control. Tracking was consistent; I didn’t see the blade wander unless I tried to force a tight curve (which you shouldn’t expect from a fine TPI straight blade anyway).

If you’re trimming face frames, scribing to baseboard, or cutting finish components to length, the results are reliably clean. For jamb extensions and thin moldings, the 20 TPI keeps fibers intact around fragile profiles.

Speed and feed

With fine teeth, patience pays. Light, steady pressure worked best, especially in hardwood and MDF. If you push, you generate heat, glazing, and premature dulling. In softwood, you can increase pace a bit, but it’s still slower than a coarse-tooth blade. That trade-off is typical: you’re using this blade for finish quality, not for demolition or rough framing.

Vibration and control

In my saw, the blade ran smoothly with low chatter, provided the workpiece was well supported. Any flex at the cut line will telegraph as chatter marks because the teeth are so close together. Clamp the work and use backing when cutting thin or brittle surfaces; it improves both feel and finish quality.

Noise was modest. Finer teeth create a more even pitch, and the cut doesn’t bark like aggressive demolition blades.

Durability

After several hours across hardwood, MDF, and PVC, the edge remained serviceable. I noticed a slight drop in bite after extended MDF work, which is expected. High-alloy steel strikes a reasonable balance between cost and life, but it’s not a “hit a nail and keep going” blade. If your work routinely involves unknown fasteners, grab a bi-metal option for those cuts and save this one for clean material.

Practical note: Wipe pitch off periodically. Resin build-up on fine teeth quickly turns into heat and burn marks, especially in pine and fir.

Value

Sold as a single blade, the value hinges on your use case. If you need a fast, consumable option for rough cutting, this isn’t compelling. If you need clean, predictable cuts in wood and plastics from a compact power handsaw, buying one or two makes sense. I’d keep one in the box as a dedicated finish blade and switch to a coarser, tougher blade for dirty work.

Where it fits

Choose this blade if:

- You prioritize cut quality over speed.

- You’re working in finish carpentry, cabinetry, trim, or plastics.

- Your power handsaw benefits from a fine, narrow-kerf blade for precise control.

Skip it if:

- You’re doing demolition or cutting near fasteners.

- You need to rip thick softwood quickly.

- You frequently cut abrasive composites and don’t want to swap blades.

Tips for best results

- Use a light feed and steady stroke. Let the 20 TPI do the work.

- Back up thin stock and melamine with scrap to minimize exit chipping.

- Keep the full tooth length engaged; partial strokes heat the teeth and reduce life.

- Clean pitch and dust from the teeth between tasks.

- Mark both faces for critical cuts; the narrow kerf makes following a line easy from either side.

The bottom line

The Bosch blade does exactly what a fine-tooth power handsaw blade should: it delivers clean, controlled cuts with minimal fuss. It’s not flashy, and it’s not meant for abuse. In the right lane—finish work, careful cuts in hardwoods, smooth edges in sheet goods and plastics—it performs reliably and feels predictable in the hand. The high‑alloy steel construction suits those tasks, and the 20 TPI tooth pattern keeps surfaces clean enough to go straight to glue or finish with only a quick sanding pass.

Recommendation: I recommend this blade for anyone using a power handsaw in trim, cabinetry, or general finish carpentry who needs a fine, consistent cut in wood and plastics. It earns its keep on clean material where surface quality matters. If your work skews toward demolition, hidden fasteners, or abrasive composites, choose a tougher, coarser blade for those jobs and keep this one as your finish option.

Project Ideas

Business

On‑Site Trim and Molding Fitting

Offer a mobile service installing and modifying baseboards, crown, and casing. The 20 TPI blade provides finish-ready cuts on thin, prefinished moldings with minimal tear-out, and the compact tooth length enables precise plunge and scribe cuts in tight spaces around returns and corners.

Custom Picture Framing Pop‑Up

Set up a micro-shop for made-to-order frames using thin hardwoods and veneered moldings. Advertise clean miters and tight joints made possible by the fine/regular cut blade. Upsell splined corners and floating frames; produce same-day orders with minimal sanding and touch-up.

Drawer Dividers & Closet Inserts

Create bespoke drawer dividers and closet organizer inserts from birch ply and thin hardwood slats. The 20 TPI blade yields clean, chip-free cuts on thin panels, ensuring press-fit slots and tidy edges that look professionally made.

Acrylic Signage & Retail Fixtures

Provide small-batch acrylic nameplates, shelf talkers, and product risers. The fine-tooth blade cuts 1/8–1/4 in acrylic with clean edges when run slow, ideal for boutiques and cafes needing quick turnaround without laser lead times.

Careful Deconstruction & Salvage

Specialize in removing baseboards, casings, and built-ins for reuse. The compact 5.75 in tooth length and fine teeth allow controlled, low-vibration cuts to free nails and seams with minimal damage to walls and trim, preserving resale value of reclaimed materials.

Creative

Geometric Inlay Coasters

Use the 20 TPI blade to cut thin hardwood veneer and 1/8–1/4 in plywood pieces with minimal tear-out for crisp geometric inlays. The fine tooth pitch and HAS construction give clean edges that glue up tightly, reducing sanding. The compact 5.75 in tooth length helps with controlled plunge cuts into small panels.

Gallery-Grade Picture Frames

Rip and miter delicate molding strips for a set of minimalist picture frames. The fine/regular cut of 20 TPI yields smooth miters on thin stock and prevents chipping on veneered moldings. Add splines or keys by making careful plunge slots using the short blade for extra strength and a boutique look.

Secret-Mechanism Puzzle Box

Build a small puzzle box with sliding panels and hidden tracks. The high-tooth-count blade lets you make tight, precise kerfs for sliders and stops in hardwood. Use the compact 5.75 in cutting length to work inside the box for flush and relief cuts without overcutting exterior faces.

Acrylic Desk Organizer

Cut 1/8–1/4 in acrylic sheets into interlocking partitions for a desk caddy. The 20 TPI blade reduces chip-out and melting when paired with slow feed and masking tape on cut lines. Finish edges with a quick scrape and polish for a clean, modern look.

Miniature Furniture & Trim

Craft dollhouse furniture and architectural trim from basswood/balsa. The fine tooth pitch allows delicate cuts on thin profiles like chair backs, window muntins, and crown details without fuzzing, making assembly easier and cleaner.