Features

- 4.0 CFM delivered at 90 PSI for faster recovery

- Dual soft start valves to assist cold-weather starts

- Oil‑lubricated pump for increased durability

- Cast iron cylinder to extend pump life

- 10" pneumatic wheel and handle kit for mobility

- Top load panel with positioning holes (transports loads up to 100 lb)

- High‑flow regulator for increased performance

- Run multiple tools from dual universal quick couplers

- Ball valve drain for quick and thorough tank draining

- Convenient cord wrap for storage

Specifications

| Amps | 14 |

| Color | Yellow |

| Compressor Tank Capacity (Gal) | 4 |

| Horsepower (Hp) | 1.1 |

| Portable | Yes |

| Lubrication Type | Oil (oil‑lubricated pump) |

| Air Delivery (Cfm @ 90 Psi) | 4.0 |

| Maximum Pressure (Psi) | 125 PSI |

| Motor Type | Induction |

| Noise Level (D B) | 83.0 |

| Number Of Pieces | 1 |

| Power Source | Corded electric |

| Voltage (V) | 120 |

| Product Height (In) | 23.0 |

| Product Length (In) | 22.0 |

| Product Width (In) | 18.5 |

| Product Weight (Lbs) | 87 |

| Pump Type | Oil lube |

Related Tools

Related Articles

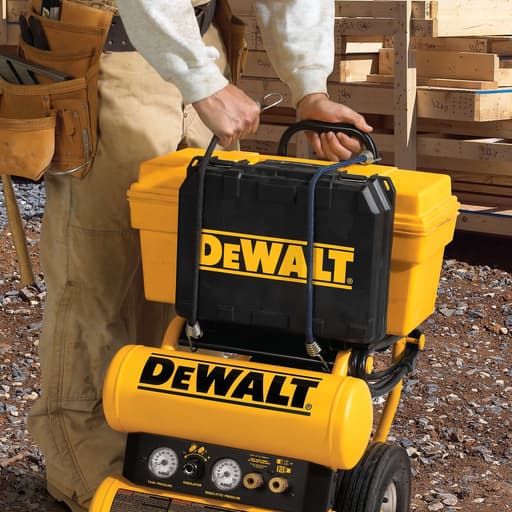

Electric, corded wheeled dolly-style air compressor with a 4‑gallon tank and a 1.1 HP motor. Delivers approximately 4.0 CFM at 90 PSI. Uses an oil‑lubricated pump with a cast‑iron cylinder for durability and includes dual quick couplers, a high‑flow regulator, dual soft‑start valves for easier cold starts, a top load panel that can carry up to 100 lb, 10" pneumatic wheels and a handle for mobility, a ball‑valve tank drain, and cord wrap for storage.

DeWalt 1.1 HP Continuous 4 Gallon Electric Wheeled Dolly-Style Air Compressor with Panel Review

The portable compressor I keep reaching for

I didn’t expect a 4‑gallon, dolly‑style unit to replace both my small trim compressor and my heavier shop unit in day‑to‑day use, but that’s what happened with this DeWalt 4‑gallon compressor. It hits a useful sweet spot: compact enough to wheel into a finished space, stout enough to keep up with real work, and designed with more jobsite sense than most portable compressors I’ve used.

Setup and first impressions

Out of the box, the compressor looks like it’s meant to survive a van ride with other tools. The roll‑cage frame shields the pump and motor, the panel up top is flat and sturdy for stacking gear, and the controls are well guarded yet easy to reach. At 87 pounds, it’s no featherweight, but the 10" pneumatic wheels and long handle make it a true dolly—you roll it, you don’t carry it.

Electrical is straightforward: 120V, 14 amps. It ran fine on a dedicated 15‑amp household circuit; on a jobsite, I avoid daisy‑chained cords and use a 12‑gauge extension if I have to run long. The induction motor comes up to speed confidently, and the dual soft‑start valves help keep inrush manageable.

Build quality and mobility

The pump is oil‑lubricated with a cast‑iron cylinder—an old‑school choice that I appreciate. Oil‑lube units tend to last longer and run smoother than lightweight, oil‑free designs. You’ll have routine maintenance (more on that later), but you get durability in exchange.

The wheeled dolly frame is genuinely useful. The handle locks in and out smoothly, and the balance point is right; it tips back without feeling top‑heavy. The top load panel carries up to 100 pounds, and the holes make strapping down a nailer case or a hose bundle simple. Just don’t treat any plastic guards like a step; this isn’t a ladder.

The wheels roll over cords and gravel well. Being pneumatic, they ride softer but can lose air. One of mine arrived a bit low; topping it up solved it, but I’ll keep an eye on tube pressure seasonally.

Controls and usability

Controls are clean and familiar: dual quick couplers, a high‑flow regulator, and twin gauges that are easy to read at waist height. I like the high‑flow regulator—some lower‑end regulators give up pressure under demand; this one stays put as long as you’re within the unit’s capacity.

The ball‑valve tank drain purges the 4‑gallon tank quickly. My only nit is access: the valve sits low and slightly tucked under the frame, so if you’re working on a dusty floor or wearing gloves, it can be a bit of a reach. It’s not a deal‑breaker—still better than tiny petcocks—but an offset elbow would make it perfect.

Cord management is simple with the built‑in wrap, and the unit stores upright in surprisingly little space for something with real wheels.

Performance in real work

On paper, the numbers are modest but honest: about 4.0 CFM at 90 PSI, with a 125 PSI max. In practice, that puts this compressor squarely in the “trim to light carpentry” category, with a dash of utility work thrown in.

- Nailers and staplers: It’s excellent for brad, pin, and 15–16 gauge finish nailers. I ran two trim guns off the dual couplers at a steady pace without starving either tool. A single framing nailer is fine for punch‑list work or moderate production, but you’ll feel the recovery on rapid bursts.

- Roofing or siding: One coil nailer is workable for repair work, not ideal for sustained production.

- Automotive/light shop: Tire inflation and blow‑off are easy. A small impact or ratchet works in short bursts, but this isn’t a match for air‑hungry tools.

- Spraying: Touch‑up guns or detail work only; most full‑size HVLP setups need more air than 4.0 CFM at 90 PSI.

Recovery is a strong suit. The 4‑gallon tank doesn’t store a ton of air, but the pump refills quickly enough that cycle times stay short. For trim, that’s often more valuable than a big tank that takes ages to top off.

Noise and jobsite manners

Rated at 83 dB, it’s quieter than the typical oil‑free pancake screamers, but it’s not “quiet compressor” territory either. In a garage or open space, conversation is fine with a raised voice. Indoors, I’ll still throw on muffs if I’m near it for long runs. Vibration is well controlled; the frame and wheels don’t dance across smooth floors.

Cold‑weather starts

Cold starts are a weak spot for many small compressors. The dual soft‑start valves here do help. At around 35–40°F, mine turned over without drama and came to pressure cleanly. Below freezing, you’ll want the right viscosity compressor oil and a heavy‑gauge extension cord if you’re far from the outlet. Like any oil‑lubed unit, the thicker the oil and the colder the pump, the more sluggish the start. If you’re routinely working in sub‑freezing temps, I’d plan on synthetic compressor oil and keeping the unit in a warmer space until use.

Maintenance and longevity

You’re trading low maintenance for longevity here, and I think it’s a good trade.

- Oil changes: Check the sight glass regularly and change oil per the manual (more often if you run it hard). Use compressor‑rated oil appropriate for your climate.

- Draining the tank: The ball valve makes it quick—do it at the end of every day to keep moisture in check.

- Filters and fittings: Keep the intake filter clean, and check couplers for leaks; the high‑flow design is worth preserving.

- Wheels and hardware: Verify tire pressure occasionally and snug up fasteners after the first few trips in a van or truck.

The cast‑iron cylinder and induction motor inspire confidence. Nothing about the frame or fittings feels flimsy.

What could be better

- Drain access: The valve works well, but it’s a touch awkward to reach under the frame. An elbow or short extension would make draining easier with gloves on.

- Weight: Mobility is great on wheels, but 87 pounds is heavy to lift into a truck alone. A second grab point up front would help two‑person lifts.

- Pneumatic tires: They roll beautifully but can go soft. Solid rubber wheels would be zero‑maintenance, though less cushioned over rough ground.

Who it’s for

- Trim carpenters and remodelers who need better than pancake performance without hauling a full 20–30 gallon unit.

- DIYers upgrading from small, oil‑free compressors who want faster recovery, better ergonomics, and longer service life.

- Service techs and mobile trades who appreciate the dolly format, the protected frame, and the top panel for stacking gear.

Who should look elsewhere:

- Anyone running air‑hungry tools (grinders, sanders, big HVLP guns) or two framing guns at full production speed.

- Crews working exclusively in freezing conditions who prefer oil‑free for effortless cold starts.

Practical tips from the field

- Use a 12‑gauge extension cord if you need more than 25–50 feet; it noticeably helps start‑up and reduces voltage drop.

- If you’ll be outdoors in winter, switch to a cold‑weather compressor oil and store the unit in a heated space before use.

- Add a short 1/4‑turn extension to the drain valve if you want truly glove‑friendly draining.

- Take advantage of the top panel: strap down a hose reel or a case and move everything in one trip.

The bottom line

The DeWalt 4‑gallon compressor balances portability, durability, and real‑world performance better than most small jobsite units I’ve used. It delivers a true 4.0 CFM at 90 PSI with quick recovery, runs smoother than oil‑free competitors, and the dolly design makes transport and storage painless. It’s not silent, it’s not featherweight, and you’ll need to give it the maintenance an oil‑lubed pump deserves. But if your work lives in the realm of trim carpentry, finish work, and general jobsite tasks, it’s a dependable, thoughtfully designed tool that earns its keep.

Recommendation: I recommend this compressor to pros and serious DIYers who need a durable, mobile unit for trim to light carpentry and general jobsite use. It’s reliable, well protected, and recovers quickly, with smart ergonomics that make long days easier. If your work demands continuous, high‑airflow tools or you refuse to deal with oil and cold‑weather considerations, choose a larger or oil‑free model. Otherwise, this is a solid, confidence‑inspiring choice.

Project Ideas

Business

Mobile Trim and Molding Service

Offer on‑site installation of baseboards, shoe molding, door/window casing, and wainscoting. The 4.0 CFM at 90 PSI runs brad/finish nailers efficiently, and dual couplers let you and a helper work simultaneously. Market to realtors and renovators for quick, clean upgrades.

On‑Site Furniture Refinishing (Small Pieces)

Provide touch‑up and refinishing for chairs, end tables, cabinet doors, and headboards using an LVLP detail gun or airbrush. The high‑flow regulator ensures smooth atomization, and 83 dB noise is manageable in garages. Package services: color refresh, clear coat, and hardware swap.

Dryer Vent and Appliance Coil Cleaning

Use a long air wand and blow gun to remove lint from dryer vents and dust from refrigerator/AC coils. The wheeled dolly and top panel make it easy to transport hoses and vacs. Sell annual maintenance plans to homeowners and property managers to reduce fire risk and improve efficiency.

Event Balloon and Sports Inflation Pop‑Up

Set up at parks, youth leagues, or community events to inflate sports balls, strollers, wheelbarrows, and latex balloons. Dual couplers run two inflators at once; the high‑flow regulator speeds turnover. Offer flat‑rate stations or team contracts before games and tournaments.

Landlord/Airbnb Turnover Punch‑List

Bundle quick fixes: resecure loose trim, repair casing, adjust doors, fill nail pops, and blow out debris from tracks/vents. The compressor powers nailers and blow guns for fast, tidy results. Sell per‑unit packages with same‑day turnaround between guests or tenants.

Creative

Modern Slat Wall With Hidden Cleats

Build a living room or office feature wall with wood slats and concealed French cleats for floating shelves. Use a brad/finish nailer off the compressor (4.0 CFM @ 90 PSI is perfect for intermittent firing), keep dust under control with a blow gun between passes, and use the top load panel to carry up to 100 lb of slats and trim as you move room to room.

Airbrushed Furniture Gradient

Refinish a dresser, nightstands, or cabinet faces with a soft ombré using an LVLP detail gun or airbrush kit. The high‑flow regulator and 125 PSI max give consistent atomization for small pieces; 4.0 CFM supports detail work and light coats. Mask panels, spray thin layers, then clear coat for a boutique look.

Upholstered Entry Bench

Build a simple hardwood bench and create a tufted cushion. Use a narrow crown stapler on the compressor to attach webbing, foam, and fabric cleanly. Dual quick couplers let a helper run a second tool (e.g., brad nailer) for trim while you upholster. Roll the dolly base and stash supplies on the top panel as a mini worktable.

Skateboard/Longboard Vacuum-Free Press

Laminate veneer plies over a mold using an inner‑tube or inflatable bladder press fed from the compressor. Maintain steady pressure (40–60 PSI) with the regulator for even glue lines. The oil‑lubed, cast‑iron pump handles the longer holds while you shape and sand.

Mobile Bike Repair and Inflation Cart

Turn the compressor into the heart of a rolling bike station. Add a hose reel, Presta/Schrader inflator, and small tool rack on the top panel. Use the 10" pneumatic wheels to navigate parks/garages. Great for family garages or community tune-up days.