Features

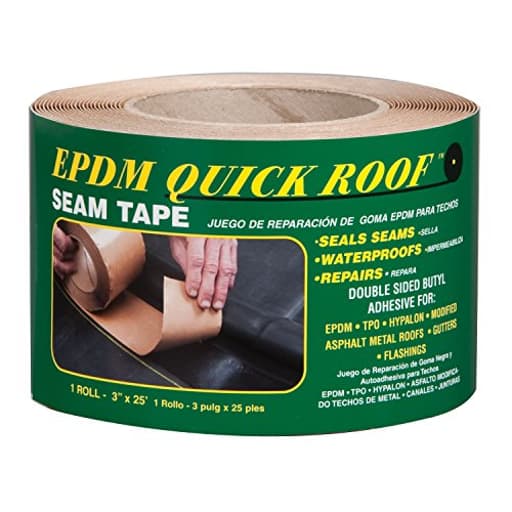

- EPDM Quick Roof Seam Tape

- Double-sided butyl adhesive

- Designed to splice two pieces of rubber together into a waterproof seam

- Use with EPDM, TPO, Hypalon, modified asphalt, metal roofs, gutters and flashings

- Size: 3" x 25'

Specifications

| Color | black |

| Release Date | 2016-03-01T00:00:01Z |

| Size | 3 inches x 25 |

| Unit Count | 1 |

Related Tools

A 3-inch by 25-foot double-sided butyl seam tape designed to create waterproof splices between roofing membranes. It is compatible with EPDM, TPO, Hypalon, modified asphalt, metal roofs, gutters and flashings and comes in black for discreet seams.

Cofair BST325 Quick Roof Butyl Seam Tape 3" x 25' Review

Why I keep a roll of this butyl seam tape in my roofing kit

I don’t often get sentimental about tape, but this butyl seam tape has become a quiet problem-solver on jobs where water loves to sneak in. I’ve used it to splice EPDM seams, bridge a drip-edge transition, and tighten up a leaking gutter joint. Each time, the result was the same: a tenacious, waterproof bond that doesn’t let go—provided I prepped properly and didn’t rush the application.

What I’m reviewing here is a 3-inch by 25-foot double-sided butyl tape, black in color. It’s designed specifically to splice roofing membranes—think EPDM, TPO, Hypalon—and it also plays well with modified asphalt, metal, gutters, and flashings. The “double-sided” part matters: this is a seam tape meant to live between layers. It’s not a surface patch with a top facer; it creates a hidden, waterproof splice.

What it is (and what it isn’t)

At 3 inches wide, the tape gives you some wiggle room on alignment while keeping seams conservative and discreet. The butyl adhesive is applied on both sides and covered by a release liner. It’s slightly under 1/16 inch thick, which is enough body to fill minor surface texture without creating a bump that telegraphs through the membrane.

Because it’s double-sided, this isn’t the tape you reach for to slap over a hole by itself. If you need a top-exposed patch, use a compatible cover strip or single-sided repair tape. This product shines when you’re marrying two clean, compatible surfaces and want that union to be watertight.

Prep matters more than anything

I’ve never had good results with any butyl product on dusty, chalky, or oily surfaces, and this tape is no exception. Here’s the prep routine that’s given me consistently strong bonds:

- Clean both mating surfaces thoroughly. On roofing membranes, I start with a dry wipe, then use a membrane-safe cleaner to remove chalk and grime.

- Use primer where required. On EPDM and TPO, I get far better adhesion and long-term performance with a compatible primer. The difference is noticeable—both in initial tack and in how the seam feels after rolling.

- Dry and warm helps. Application in warm weather is ideal. In cooler conditions, I gently warm the surfaces (not the roll) with a heat gun to improve flow and tack. Don’t overheat; you’re just taking the chill off.

- Lay out the seam and mark alignment. Since the tape is unforgiving once it touches, I dry-fit and mark with a pencil so I’m not guessing when it counts.

Application experience

The first thing you notice is how aggressively tacky the butyl is. Once the liner comes off, it wants to stick to everything, including itself. I apply it to one side first, using the release liner to handle the tape without stretching it. With the first side down and rolled, I peel the liner and bring the second layer into contact carefully, starting at one end and working toward the other to avoid trapping air.

A few practical notes from the field:

- Use a seam roller. Rolling pressure is what turns good adhesion into a watertight seam by wetting out the butyl. I roll multiple passes with firm, even pressure.

- Avoid stretching the tape. If you pull it, especially around corners, it can thin and compromise uniformity. Better to cut and lap pieces.

- Keep the tape and work area clean. A stray pebble will make a lump that won’t roll out.

- Plan for overlaps. Where two tape pieces meet, I give myself at least an inch of overlap and roll it thoroughly.

The tape cuts cleanly with a sharp utility knife. Keep extra blades handy—gummy edges dull blades quickly.

Performance in real use

EPDM seam repair: I used it to re-splice a failing seam where an EPDM sheet overlapped a curb flashing. With primer and proper rolling, the butyl grabbed immediately and relaxed into the micro texture of the EPDM. After a year of exposure beneath a termination bar and cover layer, there’s no edge lift and no evidence of water infiltration.

Drip-edge transition: On a low-slope roof where a rubber membrane ran over an aluminum drip edge, thermal movement used to crack the sealant bead. The butyl seam tape, sandwiched between rubber and metal, created a flexible joint that has stayed bonded through seasonal expansion. It’s not exposed to sunlight in that setup, which is ideal for long-term durability.

Metal gutter joint: I’ve used short lengths between nested aluminum gutter sections before riveting. It functions as a compressible gasket and adhesive in one, and unlike many mastics, it doesn’t shrink or go brittle. Just remember: because it’s double-sided, you’re bonding metal-to-metal with compression—not capping a leak from the outside.

Under foot traffic or ponding, the tape performs best when it’s protected—either by the overlapping membrane, a patch, or flashing. Butyl is robust, but continuously exposed edges are an invitation for dirt pickup and eventual edge contamination. Keep it sandwiched and rolled, and it holds up.

Handling and storage

- Store it cool and flat. Heat can encourage the butyl to cold-flow and stick to the liner edges.

- Keep the release liner clean during application. If you drop it in grit and then use it as a handling aid, you’ll contaminate the adhesive.

- Black color is a non-issue when the seam is concealed, but it’s discreet enough at edges where it might peek out.

Where it falls short

- Very little repositioning: This is not a “lift and reset” product. Once it makes contact, you can peel it back, but the butyl stretches like taffy and loses that neat, uniform thickness. Plan your seam and commit.

- Not a top-surface patch: If you’re expecting a single-sided roof tape with a UV-stable facer, you’ll be disappointed. This is for splicing and sandwiching.

- Prefers warmth and pressure: In cold conditions without warming and rolling pressure, your bond will be mediocre. That’s true of most butyl tapes, but it’s worth stating clearly.

Compatibility and use cases

This tape has bonded reliably for me to:

- EPDM, TPO, Hypalon membranes (with appropriate cleaner/primer)

- Modified asphalt surfaces (smooth, clean, and primed as needed)

- Metal (aluminum, galvanized steel) for gutters and flashings

- Underlayment transitions and curb details where a hidden splice is preferable

If you’re working on a pond liner or water feature using compatible rubber, the tape can splice liners effectively. The same prep rules apply, and you’ll want full overlap and rolling pressure. Keep the splice protected from UV, stones, and abrasion.

Durability and weathering

Butyl’s strength is its flexibility and ability to maintain a seal as materials move. It doesn’t cure hard; it stays elastoplastic, which allows it to absorb thermal cycling. To maximize longevity:

- Keep the seam covered from direct UV where possible.

- Avoid creating exposed edges. Terminate under a cover strip or flashing.

- Roll thoroughly at install; most failures trace back to insufficient pressure or dirty surfaces.

In the installs I’ve revisited months and years later, the seams remained cohesive and tacky under the surface, which is what I want from a butyl splice—no brittleness, no voids, no water tracks.

Value

At 3 inches by 25 feet, a single roll goes a long way for small repairs and detail work. It’s also cost-effective compared to larger roofing kits or specialized adhesives, especially when you only need to create a few watertight splices. The double-sided format fills a niche that single-sided repair tapes don’t: hidden, structural bonding between layers without adding a top facer.

Tips to get pro-grade results

- Clean, prime, and dry-fit. The time you spend here pays back in zero call-backs.

- Use a roller. Fingers don’t deliver uniform pressure, especially across 3 inches.

- Work warm or warm the surfaces. You’ll feel the butyl relax and flow.

- Don’t stretch; cut and overlap. Maintain consistent thickness throughout the seam.

- Protect the seam from UV and abrasion. A cover strip or flashing is your friend.

Recommendation

I recommend this butyl seam tape for anyone needing a reliable, double-sided splice on EPDM, TPO, Hypalon, modified asphalt, or metal details. It’s extremely tacky, fills minor surface irregularities, and maintains a watertight seal through thermal cycling—so long as you respect the basics: clean surfaces, compatible primer where appropriate, warm application, and firm rolling pressure. It’s not a cure-all and it’s not a surface patch, but used as intended, it’s one of the most dependable ways I know to create a discreet, waterproof seam.

Project Ideas

Business

Emergency Roof Repair Kit (Retail)

Package the BST325 tape into a branded DIY emergency roof-leak kit for homeowners and landlords. Include pre-cut patches, surface cleaner/primer wipes, a small roller for adhesion, step-by-step instructions and a QR code linking to an install video. Sell through hardware stores and online marketplaces as a quick, higher-margin product for urgent waterproof repairs.

Mobile Roof & RV Seam Repair Service

Offer an on-site repair service specializing in seam failures on flat roofs, RV roofs, boats and gutters. The BST325 tape enables quick, permanent repairs without hot-air welding or large crews. Target property managers, marinas and campgrounds; price by job type and offer routine maintenance contracts to catch small leaks early.

Custom Waterproof Planter Production

Start a small manufacturing business making rooftop and terrace planter liners and boxes from EPDM/TPO with butyl-taped seams. Emphasize fast turnaround, lightweight construction and leakproof warranties. Partner with landscapers, architects and green-roof installers who need custom sizes that are difficult to source commercially.

Event Canopy & Awnings Rental + Repair

Build a fleet of modular, waterproof canopies and awnings using taped membrane panels and rent them for outdoor events, markets and film shoots. Use the BST325 for fast field repairs between bookings. Offer add-ons such as branded printing on removable skirt panels and on-site setup services to increase revenue per job.

Wholesale DIY Roof Repair Supply Packs

Create bulk-ready packs for contractors and maintenance departments: rolls of BST325, primers, applicator rollers and instructions bundled at volume pricing. Market to multi-family housing associations, commercial building services and facility managers as a time-saving, safer alternative to heat-welding small patches.

Creative

Rooftop Planter Liners

Use EPDM or TPO scrap and the double-sided butyl seam tape to build custom, fully waterproof planter liners for rooftop gardens or balconies. Cut panels to size, tape overlapping seams with the BST325, reinforce corners with extra tape layers, add a simple drainage layer and grommeted overflow. The black tape blends with liner material for a discreet finish and makes rapid, solvent-free assembly.

Custom Wading Pool or Pet Pool

Create small portable pools from EPDM or Hypalon sheets by splicing panels with the butyl seam tape. Fold and tape corners to form vertical sides, use clamps while the adhesive cures, and optionally add an exterior fabric skirt. Because the tape is compatible with common membrane materials and creates a waterproof seam, it's ideal for DIY pet pools, children’s splash tubs or temporary livestock water troughs.

Seamless Gutter-to-Barrel Rain Collection

Build a discreet, watertight connection from a gutter downspout to a rain barrel by shaping TPO/EPDM into a funnel and sealing all joints with the BST325 tape. The black tape hides inside dark gutters and resists moisture. Add a mesh filter and hose fittings to complete a neat DIY rain-capture system that won’t leak at seams.

Event Canopy Panels and Blackout Backdrops

Make modular canopy or blackout panels by joining TPO/EPDM sheets into larger panels with the double-sided seam tape. Use reinforced tape runs where grommets or tie points will be installed. The result is lightweight, waterproof panels that can be rolled up, stored, and reconnected on site for outdoor events, photography backdrops or vendor booths.

Outdoor Furniture Covers & Gear Bags

Fabricate tailored, waterproof covers for grills, patio furniture or equipment using membrane sheets and butyl seam tape for invisible, durable seams. Pattern pieces to fit, tape the seams, and add hook-and-loop or buckles. Because the tape bonds strongly to metal and rubberized fabrics, covers resist wind and rain without heavy sewing or heat welding.